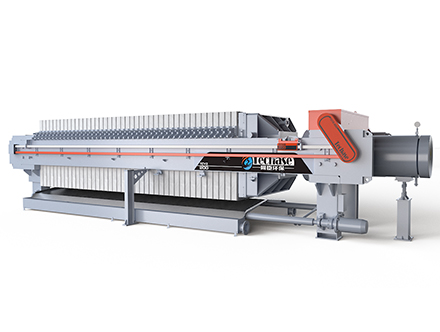

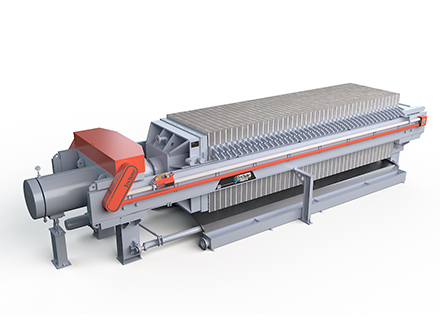

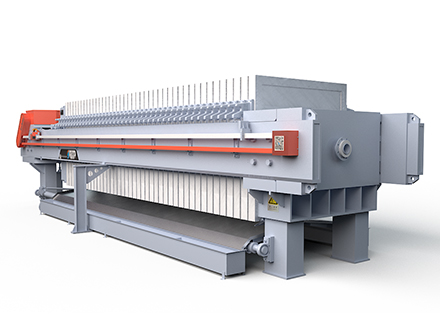

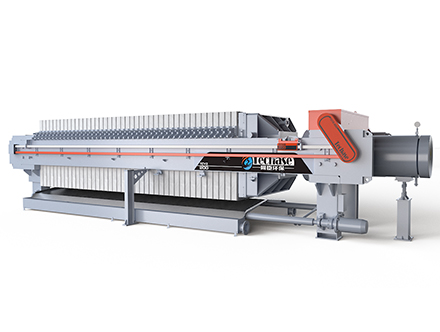

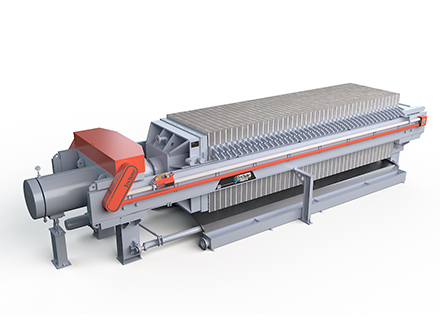

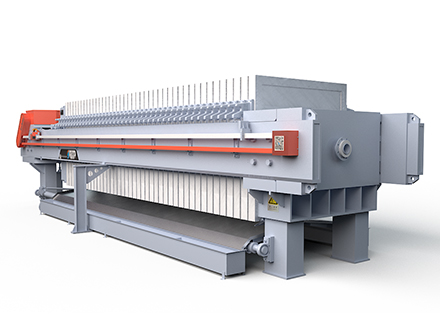

Elaspress® Super-high Pressure Filter Press-YG Series, which was developed by Techase in cooperation with Tongji University based on extensive R&D to meet customers’ requirements, is a new innovative pressure filter that is supplied for a wide range of applications in municipal & industrial industries to generate filter cakes whose dryness which, depending on the filtered materials, can even reach 80% (20% humidity) under pressure.

Equipment Composition

Skeleton

Filter Pack: filter plates made of steel fitted with filter cloths, springs of stainless steel

Automatic Plates Shifting System

Movable Drip Tray

Hydraulic System

Control Cabinet

Elastic Media Type

Press Pressure: 2.5 ~ 10MPa

Techase has optimized the structure of the conventional filter presses and ingeniously applied elastic medias of stainless steel to create pressure and reduce energy consumption. Owing to its design and innovation, when compared with other similar filter presses, Elaspress® Super-high Pressure Filter Press is considered of higher efficiency, smaller footprint, lower operation cost, higher performance and easier operation & maintenance.

Available Options

Automatic Discharge

Automatic Cloths Cleaning

PLC Remote Control

Belt / Screw Conveyor

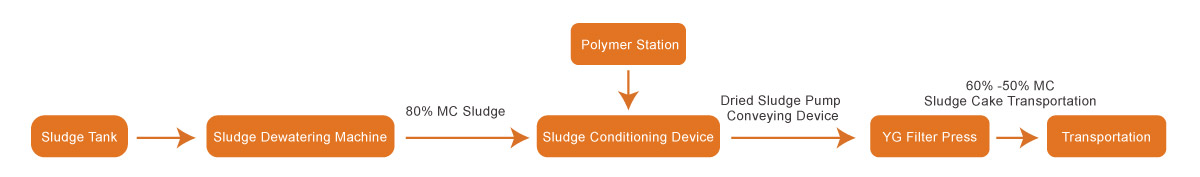

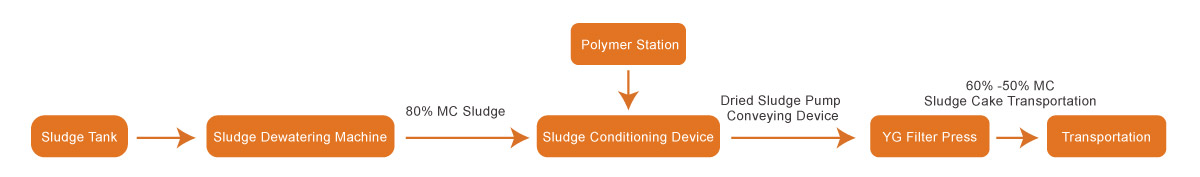

New Development – Process – YG Series

80% MC Sludge Feeding Directly

Conventional deep sludge dewatering projects generally need to control sludge MC at about 95%, and then start the final squeezing stage for deep dewatering. In this way, some sludge with 80% MC has to be diluted first which is more complex and expensive.

In response to the above problem, Techase has promoted “80% MC Sludge Feeding Directly” process, which can be connected to existing sludge dewatering machine. In face of the sludge with 80% MC, we can change the original deep sludge dewatering technology (dilute → condition), and achieve feeding sludge directly, which would simplify deep sludge dewatering process and save operation and investment cost to some extent.

Process Flow

Application

Range of Application

Sludge usually comes from (but not limited to) municipal sewage treatment plants and various industrial and mining enterprises with high moisture content sludge.

Application Site

1.Upgrading of original dewatering workshop

The original dewatering workshop has had multi plate screw press, belt filter press, centrifuge, plate-and-frame machine or other sludge dewatering machines and the sludge moisture content is about 85%-75%.

2. Centralized Sludge Disposal

It treats stock sludge (municipal sludge’s sludge pit), or sludge collected and transported by the sludge centralized disposal center with a moisture content of about 80%.

Supporting Equipment & Devices

Technological Advantages

1.80% MC Sludge Feeding Directly, Simple Technology, Low Operation Cost

It can be seamlessly connected with the existing sludge dewatering equipment in the sewage plant, on the basis of the original equipment, the sludge with 80% moisture content is directly fed into the equipment, and the original deep dewatering process of dilution and conditioning is changed.The whole process is simple and the operation cost is low.

2. Fast and High Efficient, System operation efficiency is increased by 40%

Techase adopts the new process to effectively shorten the single batch running time of YG filter press, the core equipment of deep stripping, and improves the system running efficiency by about 40%.

3. Good Performance, Stable Final Output Sludge CakeYG Filter Press has great structure strength and it can adapt 80% MC sludge feeding directly which cannot be treated by membrane filter press. Finally, the deep sludge dewatering can be realized with good effect and the moisture content of final output sludge cake can be in the range of 60%-50%.

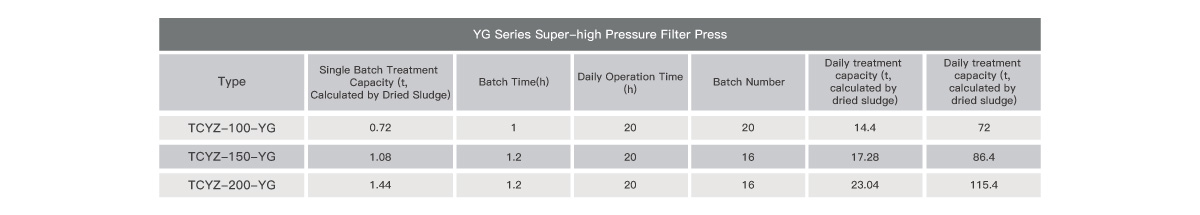

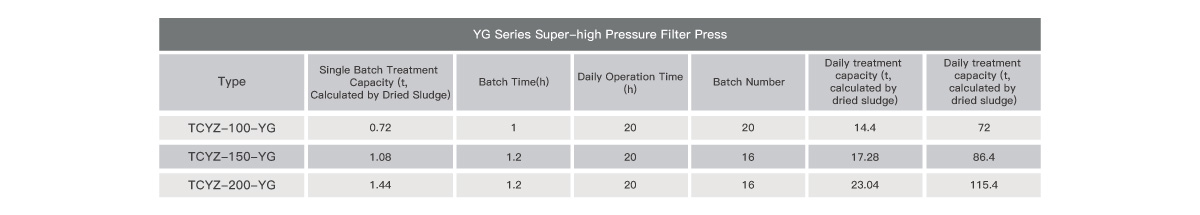

Model Table

Anhui Lingbi Sewage Treatment Plant

Main Processing Equipment: TCYZ-100-YG

Supporting Equipment: Double Screw Mixer, Conditioning Chemical Dosing Device, Dried Sludge Cake Pump, etc.

Input Sludge MC: About 80%

Output Sludge Cake MC: 60%-50%

The sludge is first dewatered by Multi Plate Screw Press, and the sludge moisture content is lowered to about 80%. Then it is transported to double screw mixer for conditioning. At the same time, the chemical is fed to the mixer. Then dried sludge cake pump transports it to YG filter press for dewatering, and the moisture content of final output sludge cake is reduced to 60%-50%.

扫一扫咨询微信客服

扫一扫咨询微信客服