At present, the general methods to treat sludge in livestock breeding industry are dehydration reduction. However, from the perspective of sludge dewatering, the sludge in livestock breeding industry has the characteristics of long fibers and large sludge output, which are easy to clog. In terms of this issue, Techase carried out innovative research and development, and launched agriculture machinery equipment called the Special Unit for Livestock Breeding Industry. It can be used for sludge and water treatment.

1.Classification, Hard to Clog

The biggest problem to treat sludge in livestock breeding industry is the machine blockage caused by long fibers. Once occurs, it will affect the treatment quality at least, and cause the damage of the machine if it is serious.

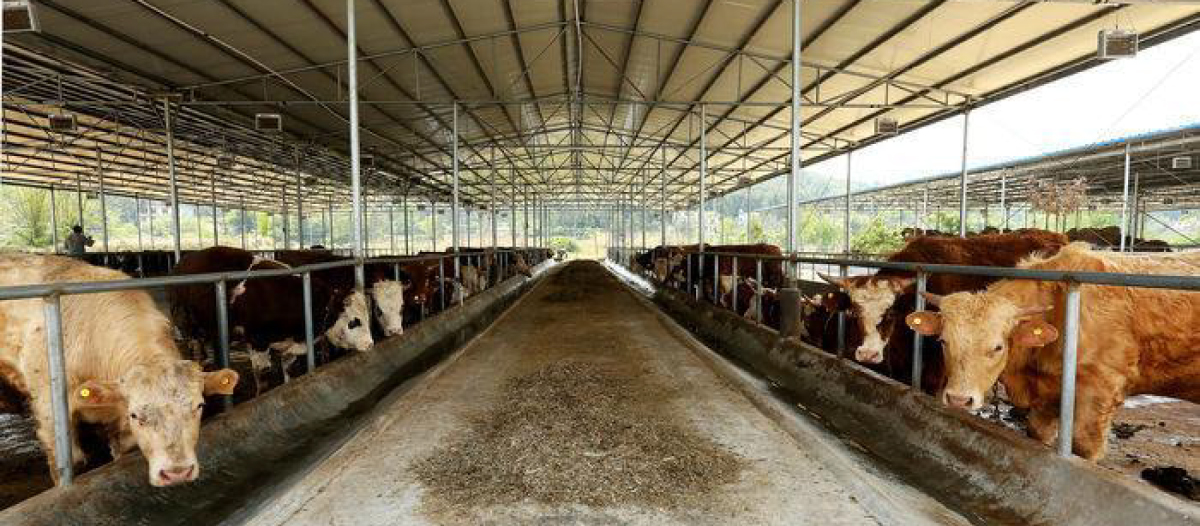

Techase Special Unit for Livestock Breeding Industry is composed of screw filter press and multi plate screw press (click to know more). The breeding sludge first enters the screw filter press for squeezing, reducing the moisture content of the long fiber material to 50% for resource utilization. At the same time, The filtrate collection tank pumps the filtrate and particle filled with organic matter into the multi plate screw press for secondary treatment. In this way, it not only solves the problem of the machine blockage, but also classifies the sludge for better treatment.

2.Less Footprint, Higher Efficiency

The production of the sludge in livestock breeding industry is large and fixed. However, the farm is different from professional sludge treatment facility, and most farms don’t have special place for sludge dewatering. Therefore, huge sludge treatment machinery is not suitable for them.

Techase Special Unit for Livestock Breeding Industry has the quality of small size, high integration, less footprint and less civil engineering cost. The screw press part adopts double-line spiral design, which has higher processing efficiency. The moisture content of 25m³ farming sludge can be reduced to about 70% per hour. Compared with similar equipment, the processing speed is doubled.

3.Automation, Simpler

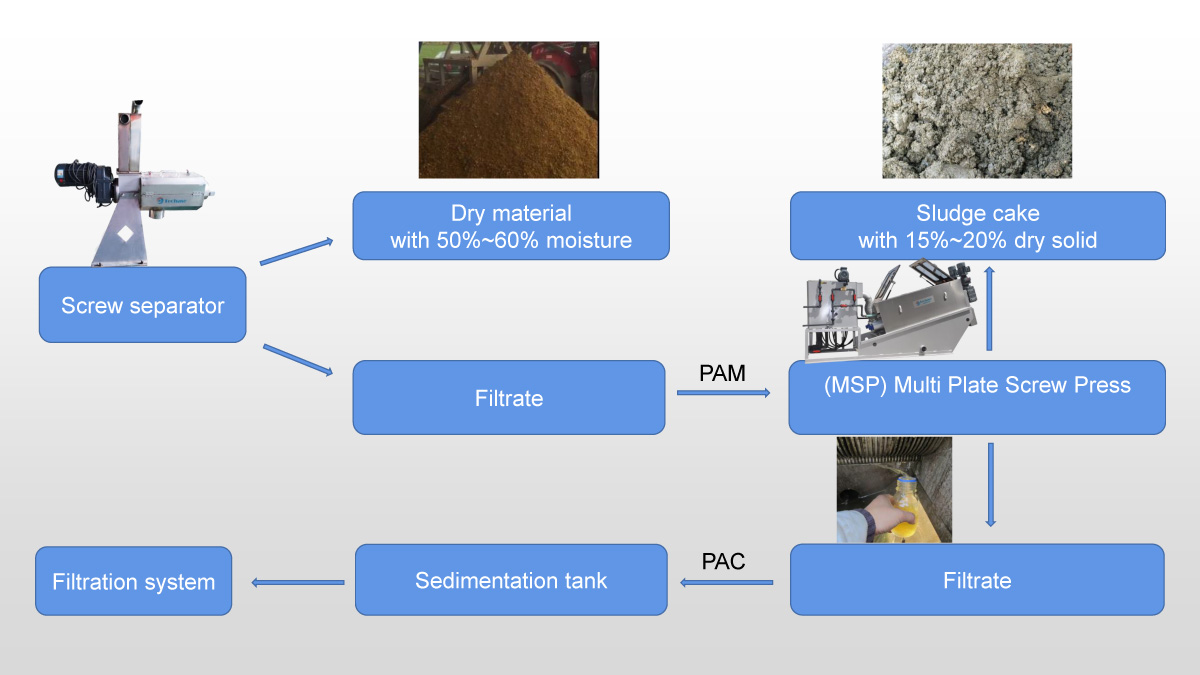

The workers have lots of work to do and the labor intensity is high. Moreover, the viruses and bacteria carried by the workers will also affect the safety of breeding. So more intelligent and simpler sludge dewatering equipment needs to be used to reduce the labor intensity and unnecessary animal contact. Techase Special Unit for Livestock Breeding Industry adopts intelligent design and one-click operation. It can be operated continuously without special care. Additionally, it has the function of self-cleaning, which can reduce labor cost significantly.

4.Special Screw Shaft, More Excellent

Techase multi plate screw press is analyzed by ANSYS model, which can adjust parameters of screw shafts according to the characteristics of breeding sludge. In addition, Techase also uses super wear-resistant cemented carbide to carry out a unique surfacing welding process on the screw shaft, which increases the thickness of the screw shaft blade by 150 times and increases the service life by nearly 7000 hours.

The industry is fully optimized and upgraded nowadays, new needs and challenges appears in environmental protection area. Techase will continue to be rooted in the sludge and sewage treatment area to improve the technical level, solve the new problems and do our best for environmental protection career.

Applications

扫一扫咨询微信客服

扫一扫咨询微信客服