Application: Pharmaceutical Industry

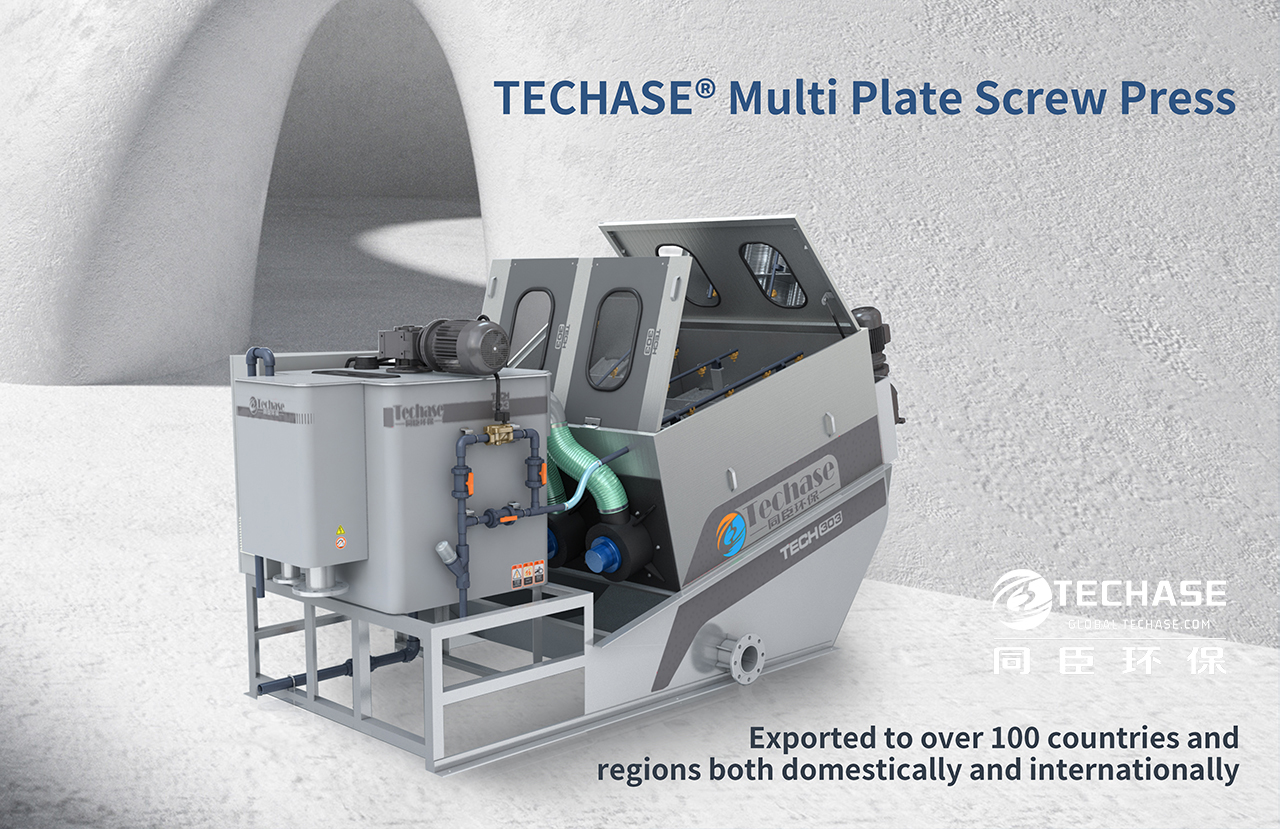

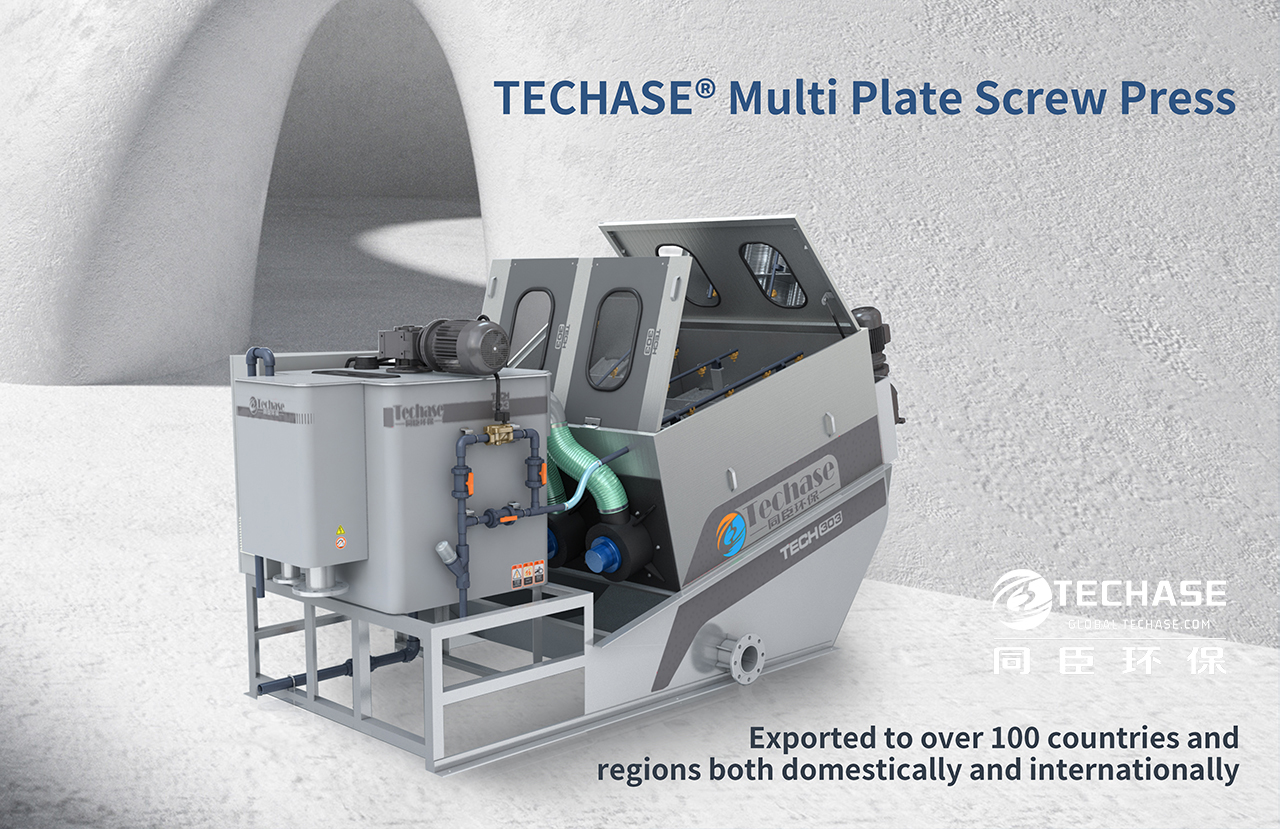

Over the past 15 years, TECHASE® Multi Plate Screw Press (MPSP) has seen tremendous development and promotion worldwide. Compared to traditional sludge dewatering equipment, TECHASE® MPSP features characteristics such as non-clogging, low energy consumption, minimal water consumption, and high degree of automation. It is worth mentioning that with the development of global new materials and control technologies, TECHASE has been continuously innovating and improving, introducing exclusive equipment for inorganic sludge, as well as "King of New Materials" CFRP annular plates with better wear and corrosion resistance, and the application of Internet of Things (IoT) technology. The case shared here involves the application of TECHASE dewatering press in sludge dewatering for a pharmaceutical company.

This pharmaceutical sludge dewatering project utilizes one set of TECHASE 402 model unit along with its supporting devices. After coagulation in the mixing & flocculating tank, the flocs enter into the dewatering cylinder. After the process, the moisture content of the discharged sludge is reduced to below 80%.

In this project, TECHASE® Multi Plate Screw Press (MPSP) sludge dewatering system has received unanimous praise for its main advantages:

1. Fully automatic operation with continuous feeding and discharging, eliminating the need for manual monitoring. It can be remotely started and stopped via LCP or PLC EC system, providing convenient and labor-saving operation.

2. Energy-saving and low operating costs. The screw shaft rotates at only 2~4r/min, and the power of a single equipment is less than 5kW. Its average energy consumption is approximately 1/8 of that of a belt filter and 1/20 of that of a decanter centrifuge.

3. The CFRP fixed rings & moving rings exhibit excellent wear resistance, with a replacement rate of less than 5% in 2 years. Their service life is more than twice that of traditional stainless steel 304 rings, resulting in lower maintenance costs.

4. The sludge in this project has a certain corrosive nature. CFRP material will not react with acids, alkalis, or salts, thereby effectively utilizing its excellent corrosion resistance. Compared to 316 stainless steel or duplex stainless steel rings, the use of CFRP rings not only improves product performance but also significantly reduces investment costs.

5. The screw shaft is hard-faced with ultra-wear-resistant hard alloy layers, with a deposition thickness 100~150 times that of ordinary spraying processes. This greatly extends the equipment's service life and reduces maintenance frequency.

The powerful product capability is the cornerstone of the long-term development of an enterprise. For many years, TECHASE Environmental Protection has adhered to placing products at the core and quality as the foundation. We have continuously advanced in research and development in equipment technology innovation, new material technology innovation, dual carbon technology innovation, and intelligent Internet of Things technology innovation. We are dedicated to creating user-friendly, practical, and highly reliable products and solutions, aiming to create greater economic and social benefits for users and address environmental issues.

扫一扫咨询微信客服

扫一扫咨询微信客服