In recent years, sludge low-temperature drying machines, with their environmentally friendly, energy-saving, safe, and efficient technological advantages, have been widely used in various industries including municipal, pharmaceutical, chemical, food, semiconductor, electroplating, and others, both domestically and internationally. The widespread application not only affirms the low-temperature drying technology but also imposes higher requirements for its development. Industry colleagues spare no effort in exploring how to expand the application scope, further improve energy efficiency, and enhance intelligence, making effective and necessary efforts.

In 2023, TECHASE unveiled its groundbreaking new generation MFTDryingTM Low Temperature Multi-Belt Sludge Dryer which adopts automatic multi-layer wet films dust collecting & removing technology, featuring technical characteristics such as dust-free operation, no bottom ash, high energy efficiency, and no attenuation. Upon its release, it quickly gained widespread market recognition. This article will focus on the "ash" and "dust" control technology of the MFTDryingTM Sludge Dryer, aiming to provide some references for customers in their selection of drying solutions.

Ash & Ash Control

Definition of “As”h: Ash, usually called Bottom Ash, refers to the sludge particles that fall through the sludge conveying drying belts into the bottom of the drying chamber.

Problem Description: The presence of bottom ash requires manual cleaning at regular intervals, increasing the workload of operating personnel. During manual cleaning, opening the maintenance door may cause odorous emissions. If bottom ash is not cleaned in a timely manner, it may be blown up by the circulating hot air, turning into dust, and thereby affecting the stable operation of the system.

Conventional Low-Temperature Sludge Dryer: Manual ash cleaning; semi-automated ash cleaning system, which only collects without lifting, requiring manual assistance in ash cleaning.

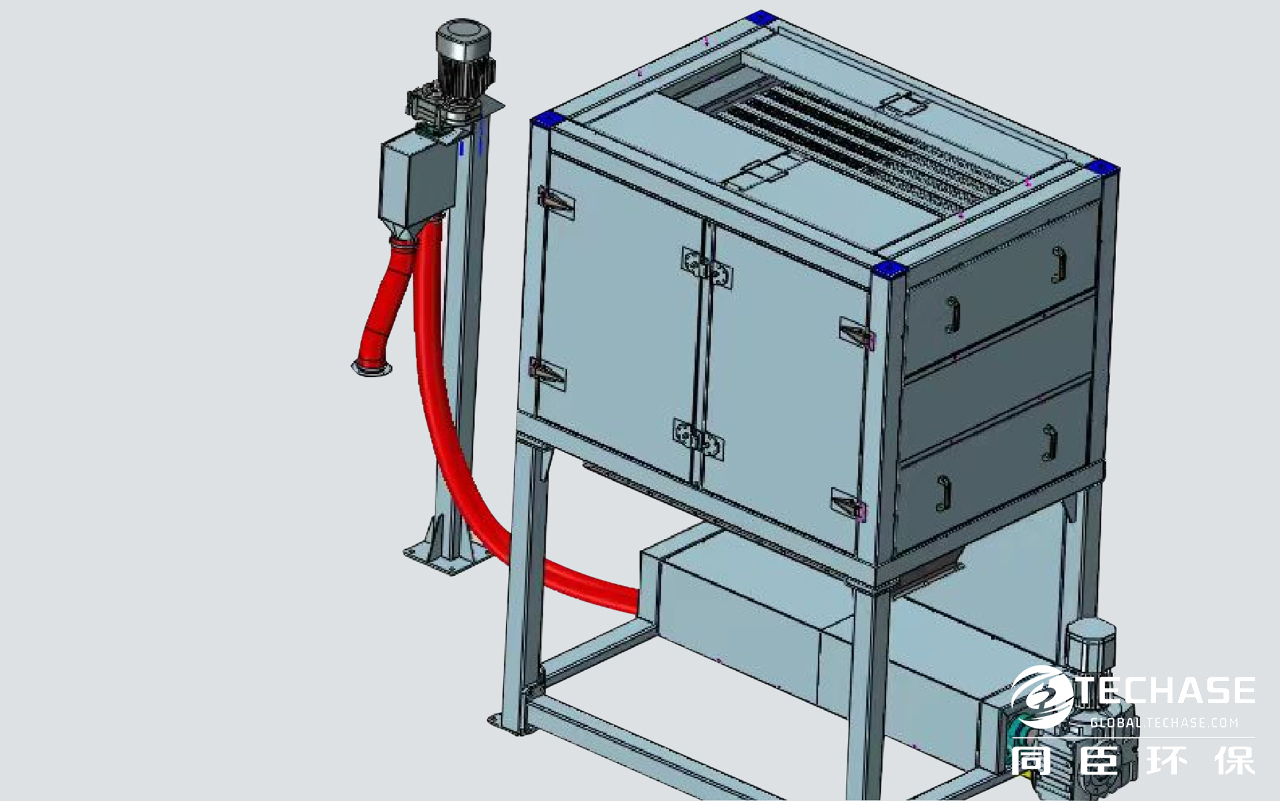

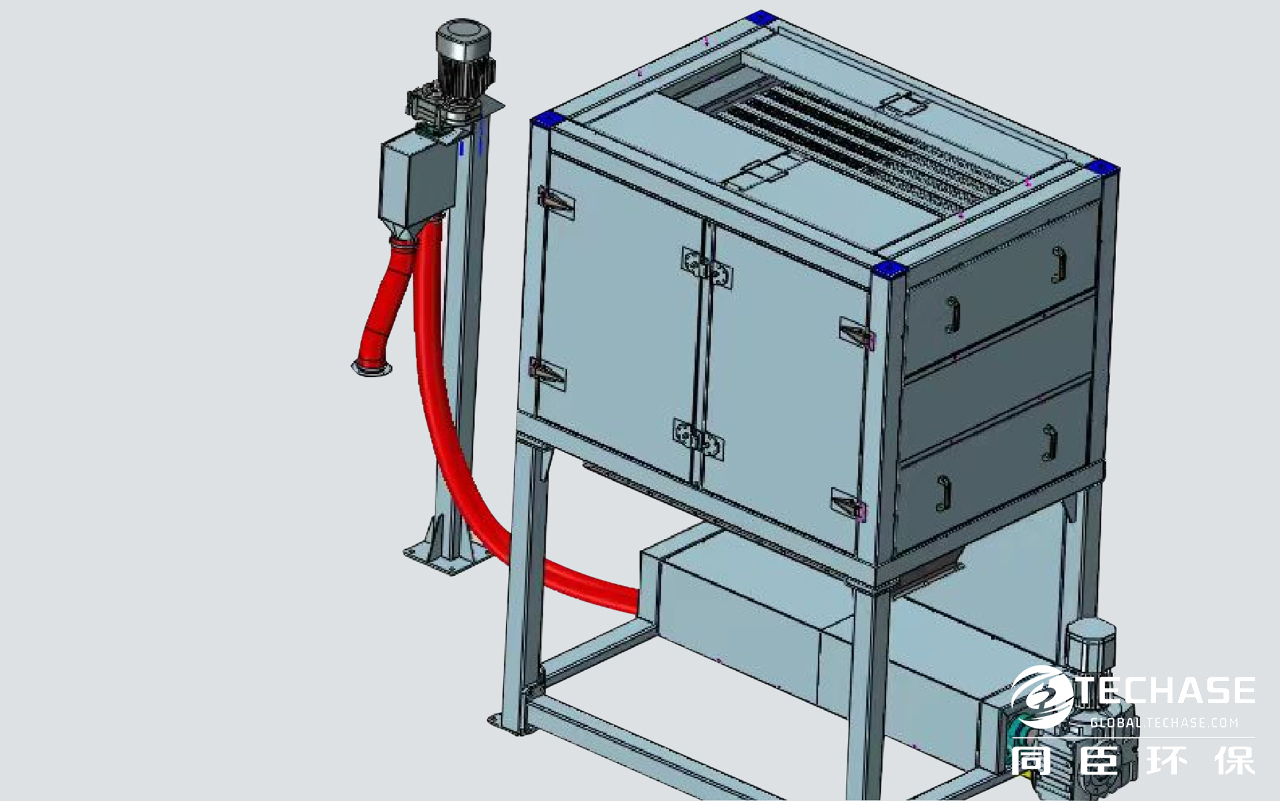

TECHASE MFTDryingTM Low-Temperature Sludge Dryer: Fully automated bottom ash cleaning system. This system is fully automated, collecting bottom ash promptly into the collection tank and transporting it to an external conveying device. The entire ash cleaning process requires no opening of maintenance doors, prevents odorous emissions, and involves no manual intervention, effectively controlling bottom ash.

Dust & Dust Control

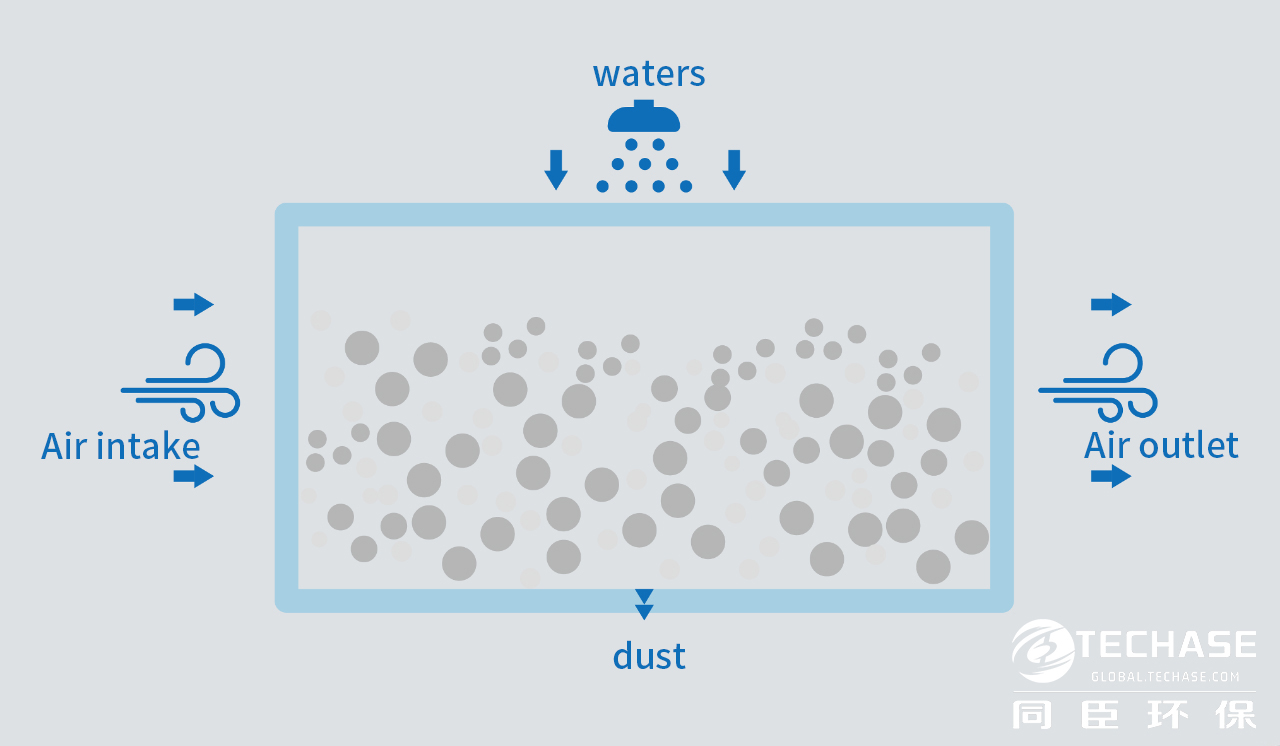

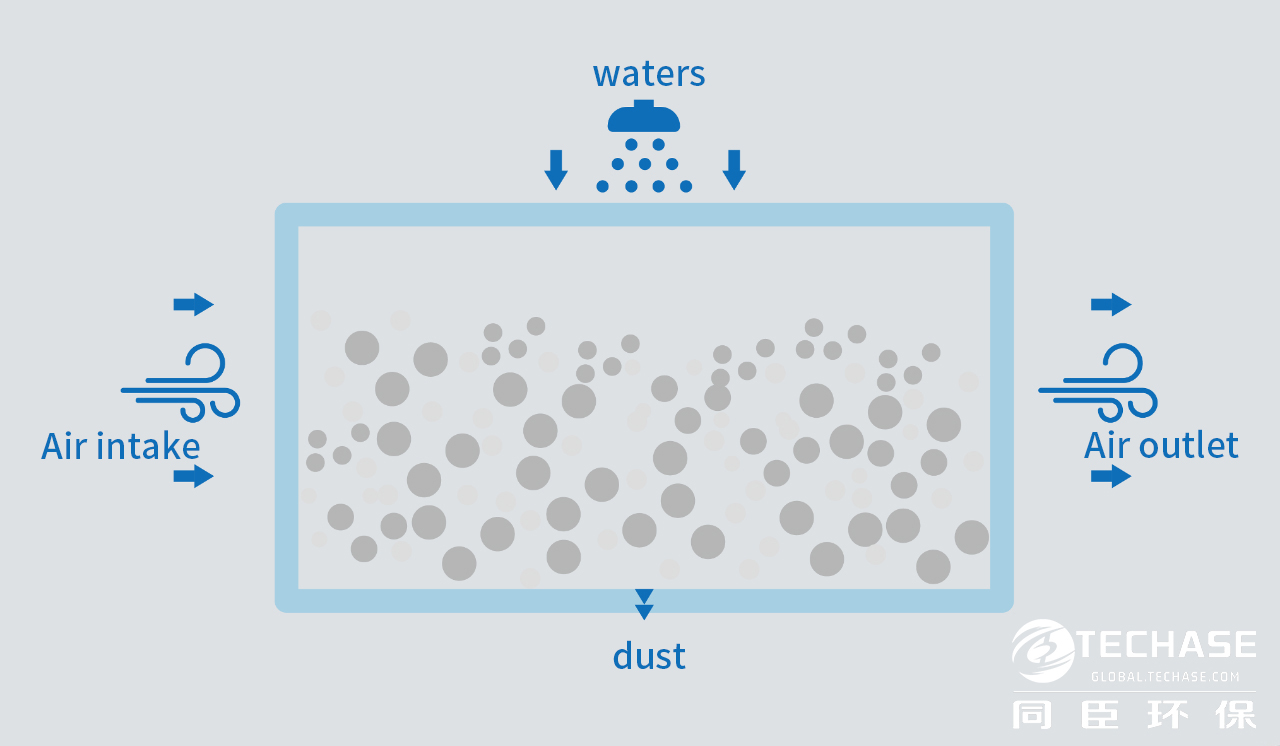

Definition of Dust: Dust, also known as airborne dust, refers to the portion of sludge particles that are stirred up by the circulating dry air during the drying process.

Problem Description: Dust accumulates in the dust removal area, requiring manual cleaning at regular intervals. Some dust particles may pass through the dust removal structure and adhere to the surface of the heat exchanger, affecting its heat exchange efficiency.

Conventional Low-Temperature Sludge Dryer: Dry static dust removal, mainly using dust removal filter bags, requiring periodic manual dust removal; dry dynamic dust removal, using pulse filter cartridges to filter dust, which are then removed by high-pressure air blowing, requiring periodic manual cleaning and replacement of the pulse filter cartridges.

TECHASE MFTDryingTM Low-Temperature Sludge Dryer: Wet film dust removal, a new type of wet dust removal technology replacing conventional dry dust removal methods. The wet film dust removal system has an impact area of over 300 square meters and millions of microchannels within a volume of 1 cubic meter, effectively capturing dust, ammonia, hydrogen sulfide, and other volatile substances in the circulating air, thoroughly solving the dust problem. The wet film dust removal system operates fully automatically without the need for manual intervention, ensuring the long-term stable operation of the sludge low-temperature drying machine.

During the operation of the low-temperature sludge dryer, the control of "ash" and "dust" is crucial. The fully automated bottom ash cleaning system and wet film dust removal system of TECHASE Multi-layer Wet Film MFTDryingTM low-temperature multi-belt sludge dryer can well solve the problems of "ash" and "dust" effectively. Of course, the presence and amount of "ash" and "dust" will vary depending on the drying materials and conditions, and cannot be generalized. If you have any needs or questions regarding sludge drying, please feel free to contact us.

扫一扫咨询微信客服

扫一扫咨询微信客服