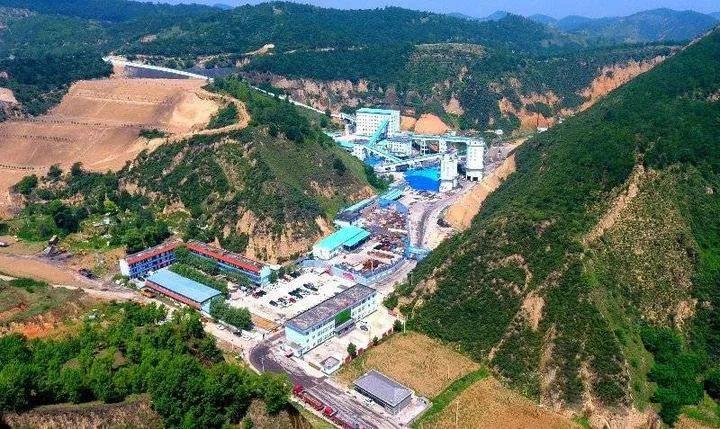

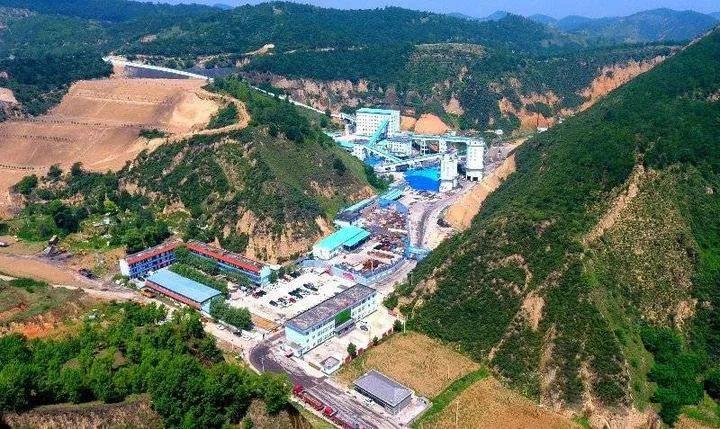

Across the Loess Plateau in northern Shaanxi and appreciate the ravines of the plateau hills. New crossovers and new challenges. This time, Techase's footprint spanned thousands of miles to the site of Yongming Coal Mine in Zichang City, Yan'an, Shaanxi. As Techase’s new cross-border challenge in the coal field, let’s take a look at the scene at Yongming Coal Mine!

Yongming Coal Mine is located in Zichang City, Yan'an, Shaanxi. The local coal seam roof and floor gangue is easy to muddy, and a large number of high-viscosity secondary coal mines will be formed during the washing process. These coal mines have fine particle size, high content, high viscosity (with the properties of kaolin), and poor water permeability, which brings certain difficulties to the treatment of coal mines. Previously, the coal mine in the coal preparation plant used direct pressure filtration. After the coal mine was concentrated, it was dehydrated with a filter press and a high-efficiency filter aid, but the dehydration effect was not satisfactory. The coal mine has a moisture content of about 35% and a calorific value of less than 900 calories. It cannot be formed into a cake and has no market value. The final wet coal mine can only be transported to the coal mine abandoned site as waste for disposal, which leads to a large amount of waste of coal mine resources and pollution of the surrounding environment, which brings greater environmental pressure.

In order to thoroughly implement the Group's strategic deployment on accelerating the construction of "above-ground coal mines", give full play to the role of the coal preparation plant as a growth point for coal economic efficiency, and improve the overall efficiency of coal. At the same time, it completely solves the difficult problem of Yongming coal tailing slime, realizes up-sales sales and coal mine-free production in the mine, and reduces the pressure on environmental protection. Based on the actual situation of the Yongming Coal Preparation Plant, the project has introduced 2 Techase CS type special coal & mining super high pressure filter presses to carry out deep dehydration for the tail coal mine. The moisture content of the coal cake is within 17%, and the coal cake is not dried. It is crushed and blended into the medium coal to form new coal for sale, realizing the huge economic benefits of tail coal mine from discarding waste to creating profits. While meeting the requirements of environmental protection policies, the comprehensive utilization capacity of coal will be thoroughly improved.

Coal Mine Processing Site

Technical Highlights

1. The coal mine is completely dehydrated, the water content is within 17%, and the coal mine has a high comprehensive utilization rate;

2. No need for heat source, direct mechanical pressing, low carbon and environmental protection, no environmental protection pressure;

3. The processing capacity is large, the operating cost is low, and the coal mine's value-added and profit-making results are remarkable;

4. High structural strength, long service life, stable and reliable operation;

5. High degree of automation, reducing on-site labor costs.

New cross-industry and new challenges. Facing brand-new industry challenges, Techase will continue to leverage its technological advantages in innovation and R&D, expand its territory in the coal field, and continue to move forward. Strictly demand ourselves with higher product quality and innovative technology, and contribute to the realization of coal resource quality, efficiency and comprehensive utilization.

扫一扫咨询微信客服

扫一扫咨询微信客服