The beautiful scenery of nature is endless, and each has its own style, but the scenery in the south of the colorful clouds is definitely unique. Whether it is the breathtaking mountains, rivers, and seas, or the long-standing ethnic culture, they are all fascinating places. Travel all over the country's great mountains and rivers, and travel to every corner of environmental governance. This time Techase's footsteps came to the wastewater treatment plant in Huize County, Qujing City, Yunnan Province. As the saying goes, the beauty of the world lies in continuous exploration and discovery. Now that it is here, let's take a look at how the local wastewater plant sludge is treated!

Project Overview

The Huize County Wastewater Treatment Plant was built in 2015 and is located in the north of Huize County. The plant area uses more advanced wastewater treatment technology. The designed scale is 50,000 cubic meters per day, and the daily wastewater treatment scale reaches 40,000 cubic meters per day. The project investment is close to 69.79 million yuan. It aims to strengthen the construction of local wastewater treatment and improve the wastewater treatment capacity of the county. After the completion of the wastewater plant, the surrounding water environment has been greatly improved, and it plays a very important role in the treatment of water pollution, the protection of the water quality of the local river basin and the ecological balance.

The project uses Techase TCSD14400HC heat pump Low Temperature Sludge Dryer. The daily sludge processing capacity is 20t/day, the feeding water content is 80%, and the output moisture content is 10%~50% (freely adjustable). The equipment operates continuously for 24 hours. The dried mud after the final drying is directly transported for disposal.

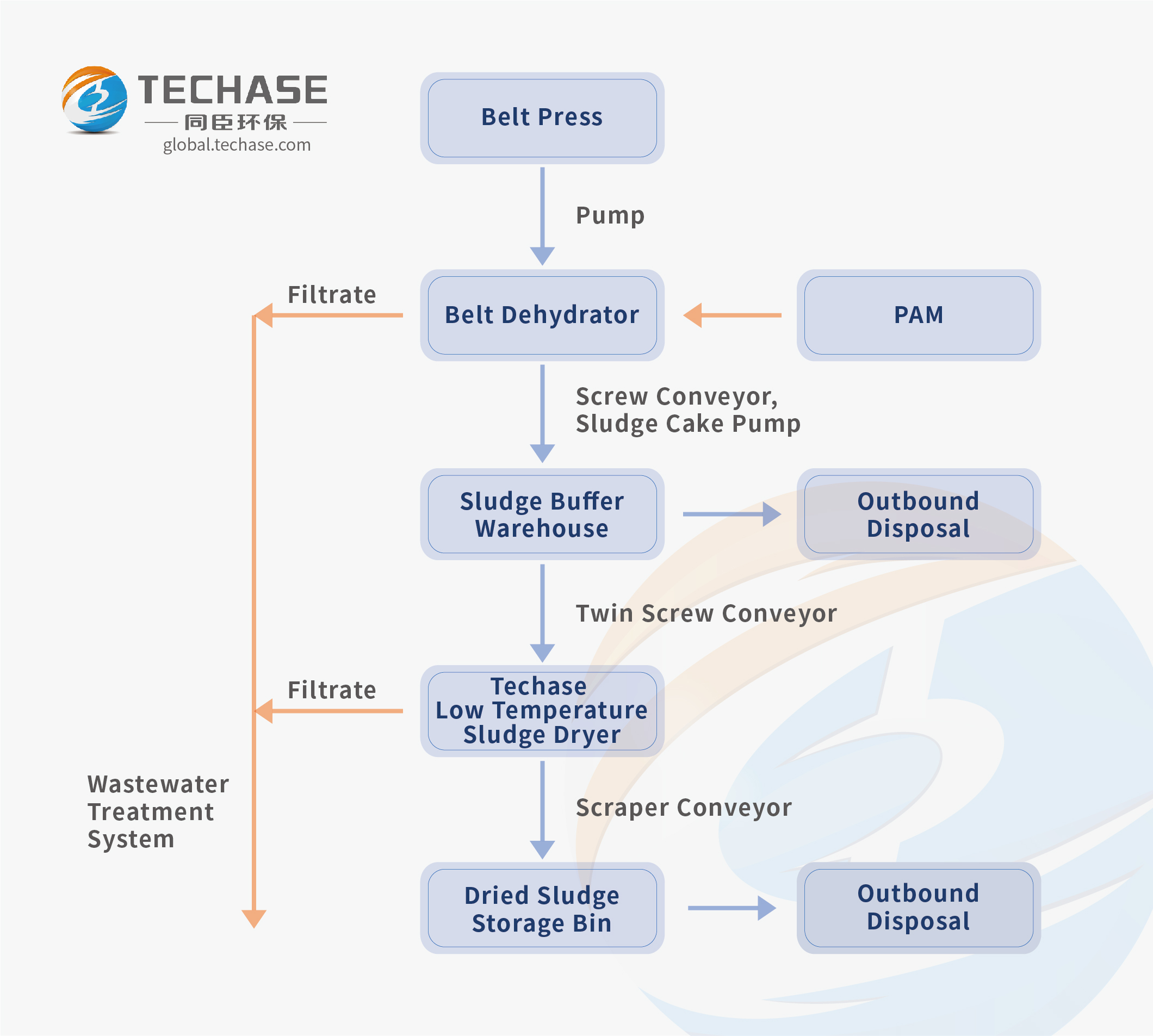

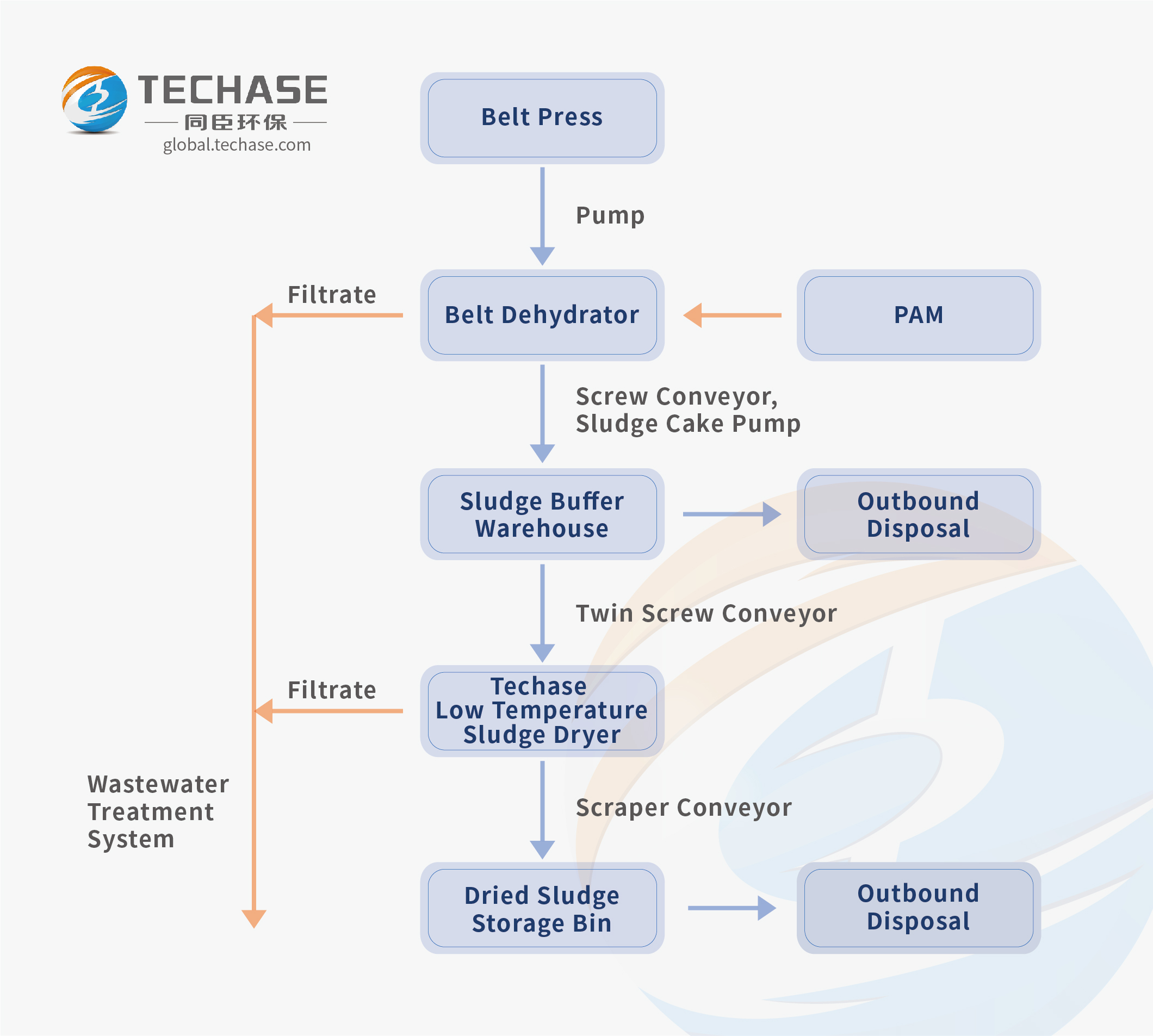

Process Flow

Existing sludge in the wastewater plant is processed by a belt dewatering machine, with a moisture content of about 80%, and then transported by a screw conveyor and a sludge cake pump to the sludge buffer bin for buffer; then it is sent to the Techase Low Temperature Sludge Dryer by a twin screw conveyor. After drying, the moisture content of the dried mud is 10%~50% (adjustable), and then it is sent to the dry silo through a scraper conveyor for storage, and finally loaded and transported out of the car for disposal.

Principle of Drying

After the sludge dewatered by the belt press is granulated, it enters the Techase low temperature sludge dryer. After the sludge is evenly distributed on the conveyor belt through the sludge distributor in the equipment, it is transported by the crawler belt and provided by the circulating fan. The flowing hot dry air takes away the moisture and finally realizes the discharge of the dry sludge; the flowing hot dry air increases the evaporation rate of the water in the sludge. Heating, re-participate in the sludge drying process, and circulate in turn.

Drying Treatment Site

Technology Highlights

1. Thorough reduction, moisture content can be as low as about 10%, and wide applicability. It can be seamlessly connected with conventional dehydration equipment such as Techase screw press, belt machine, filter press, etc.;

2. The drying temperature is below 70℃, the output is granular, there is no danger of dust explosion, the safety is high, and it can be stored directly;

3. Energy recycling, energy saving and high efficiency, no odor overflow, no need for deodorization and flue gas treatment equipment, low operating cost;

4. High-performance structure and material design, stable equipment system, long service life, simple installation and maintenance;

5. The equipment is fully automatic, no need to be on-site, and the labor cost is low.

The beautiful natural treasures need to be guarded by all of us. As an environmental protection company, it not only shoulders the responsibility of environmental protection, but also needs to be far-sighted, explore various challenges in the environmental field from a higher perspective of the industry, and strengthen the construction and development of environmental protection. Sustainable energy contributes its own strength.

扫一扫咨询微信客服

扫一扫咨询微信客服