With the rapid development of the urbanization economy, my country's wastewater treatment technology has rapidly improved, and more and more urban wastewater treatment facilities are being built to perfection, which provides an effective guarantee for urban wastewater treatment. But at the same time it also brings another environmental problem, that is, how to deal with large quantities of sludge.

The sludge has a complex composition and various types. At present, the main methods for sludge disposal in the world are sludge landfill, sludge incineration, and land resource utilization. Several disposal methods have their advantages and differences in application, but also have their own shortcomings. For example, sludge landfill will have problems such as difficult mechanical compaction, difficult filtrate treatment, and serious odor pollution; sludge incineration has problems such as high energy consumption, high treatment costs, and generation of dioxin harmful gases; land resource utilization Utilization will deal with problems such as long cycle and large area. On the whole, realizing the harmlessness, reduction, recycling, and stabilization of sludge is an environmental issue that needs to be continuously tackled and improved.

Sludge Aerobic Composting Technology

In recent years, sludge aerobic composting technology has been applied in sludge disposal. It is a harmless, volume-reducing, and stabilized sludge comprehensive treatment technology, because of its many ways to use fermented products (woodland utilization, landscaping utilization, landfill cover soil, etc.), low investment and operating costs, The wide range of application and other characteristics have attracted wide attention. There are three common composting processes, namely: stack type, bin/tank type, and reactor. The basic principle is that the microbial community decomposes and converts the organic matter in the sludge into carbon dioxide, water, inorganic matter and biological cell material under the condition of proper nutrition, moisture and ventilation conditions, releases energy at the same time, and improves the solid waste into a stable Humus improves the fertilizer content of sludge.

(The picture shows the Techase Jiangling aerobic composting project site.)

Techase Gangling Aerobic Composting Project

The project is based on the principle of "harmlessness + reduction + resource utilization" and adopts the process route of "trough high temperature rapid aerobic composting technology + land utilization" to treat biogas residue and sludge. The source of front-end sludge is thin sludge (water content 98%), dehydrated sludge (moisture content 80%), sludge cake (moisture content 70%), and the total amount of sludge entering the fermentation system is 15t/d; the scale of composting products is The annual output is about 2500~4000 tons of powdered greening substrate, which can be used for landscaping in the later period.

Technical Principle

The aerobic composting technology launched by Techase is based on the process of humification of organic solid waste by the action of aerobic microorganisms under aerobic conditions. In this process, the soluble substances in the sludge are directly absorbed by the microorganisms through the cell walls and cell membranes of the microorganisms; secondly, the insoluble colloidal organic substances are adsorbed outside the microorganisms, and the extracellular enzymes secreted by the microorganisms are decomposed into soluble substances and then penetrate into the cells. Microorganisms carry out catabolism and anabolism through their own life metabolism activities, oxidize part of the absorbed organic matter into simple inorganic matter, and release the energy required for biological growth activities; synthesize another part of the organic matter into new cell materials, so that the microorganisms Grow and reproduce, producing more organisms.

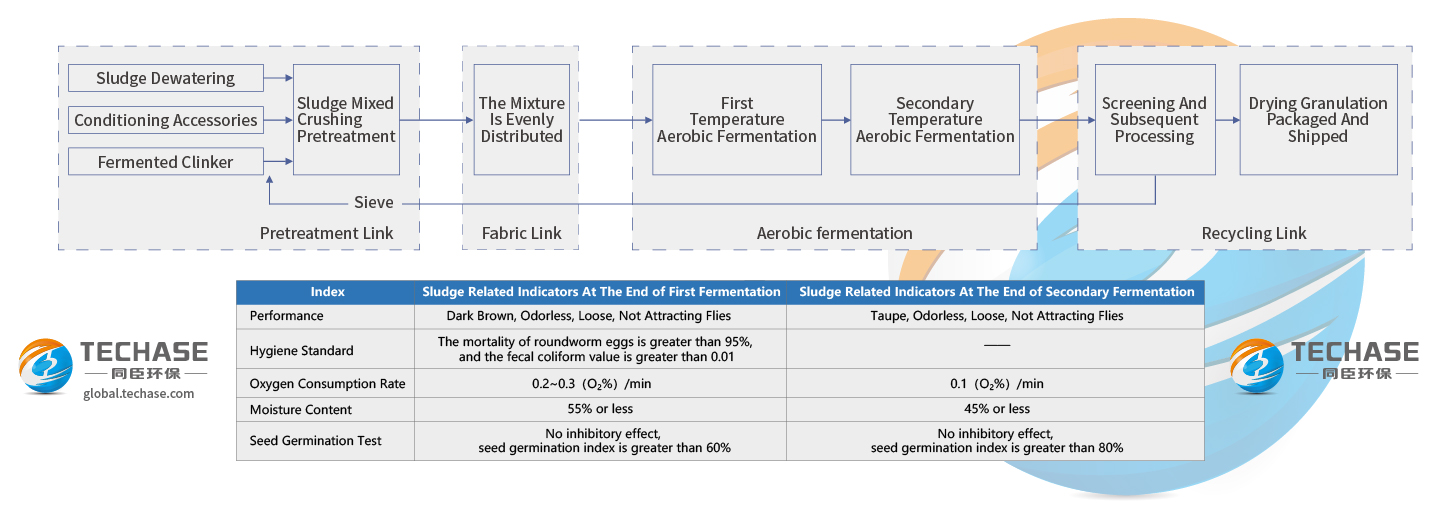

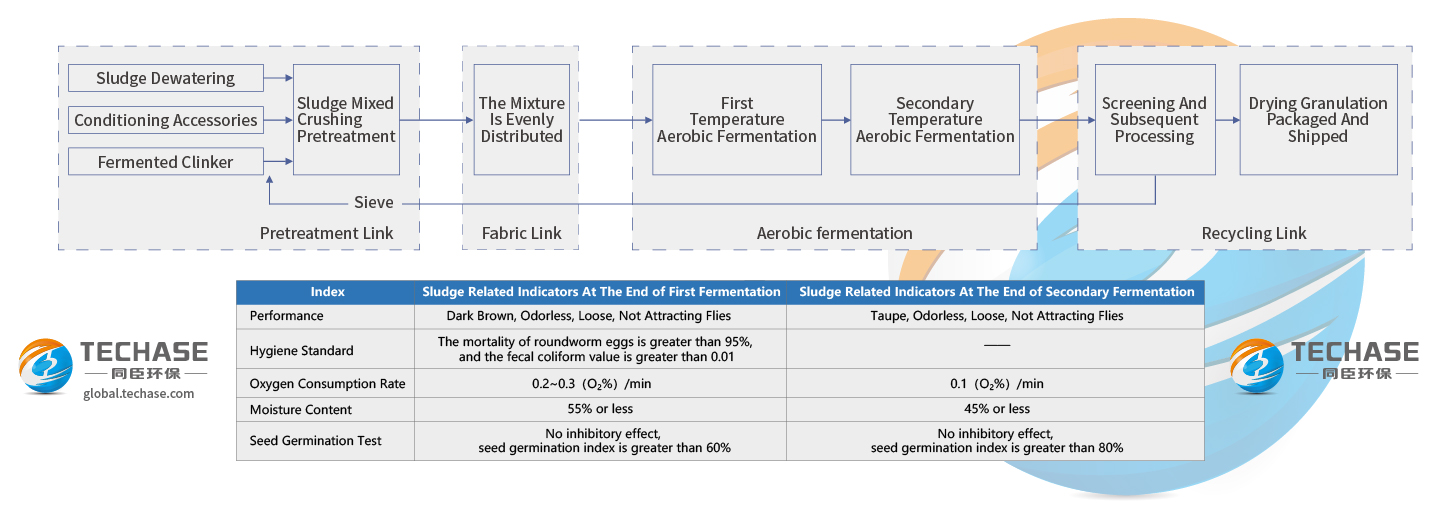

Process Flow

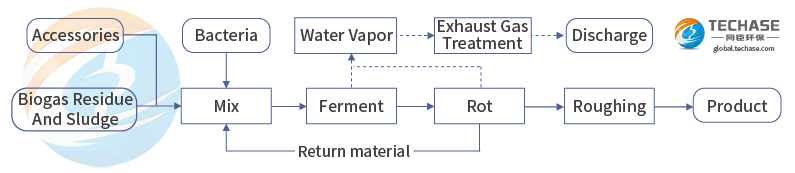

The technological process of biogas residue and sludge treatment mainly includes: mixed pretreatment, primary fermentation (composting), secondary fermentation (composting), rough processing, exhaust gas collection and treatment.

Mixed Pretreatment: adjust the particle size, moisture and carbon-nitrogen ratio of the material, and add bacteria to promote the rapid fermentation process.

Primary Fermentation (Composting): Decompose the volatile substances in the waste, kill the parasite eggs and pathogenic microorganisms, and achieve the goal of harmlessness. Reduce the moisture content, the organic matter is decomposed and mineralized to release nutrients such as N, P, K, and at the same time, the nature of the organic material becomes loose and dispersed.

Secondary Fermentation (Complaint): The organic solid waste after the first composting fermentation has not yet reached maturity, and it needs to continue the secondary fermentation, that is, aging. The purpose of aging is to further decompose, stabilize and dry the remaining macromolecular organic matter in the organic matter to meet the requirements of the subsequent fertilizer production process.

Rough Processing: improve the commercial nature of compost products and improve overall economic benefits.

Process Technology Characteristics

1. The treatment process is composed of pretreatment system, fermentation system, aging system, ventilation and aeration system, central control system, and fertilizer processing system, which can be flexibly combined according to the treatment volume;

2. The fermentation process adopts forced ventilation dynamic fermentation, and forced ventilation is intermittent segmented aeration to ensure proper supply of oxygen during the fermentation process and maintain high activity and efficiency of microorganisms; product quality is stable, and the fermentation cycle is 15 days, which is the same as the traditional composting cycle. Compared with 40 days, the efficiency is obvious;

3. The automatic feeding and discharging system can realize the mechanization of the whole process of material conveying, loading and unloading, including feeding belt conveyor, mobile cloth belt conveyor, discharge belt conveyor, etc.; this system can reduce personnel and transportation vehicles in the workshop and reduce operation cost.

As an innovative company that has been deeply involved in the environmental protection field for 13 years, Techase has always adhered to the original intention of environmental protection, actively explored continuous challenges, and is committed to providing innovative and upgraded, efficient and intelligent environmental protection equipment and technical solutions for wastewater and sludge treatment, with a high sense of responsibility And a sense of mission to solve environmental problems for the majority of users, and jointly build a beautiful and harmonious green environment!

扫一扫咨询微信客服

扫一扫咨询微信客服