Above 95% waste in the vegetable market includes rotting vegetable leaves, meat, foam and other waste. If not handled in time, the environment would become bad and foul smell would spread everywhere, which could easy to breed bacteria to bring health hazards. Moreover, the wet waste has characteristics of large amount and easy accumulation, which leads to increase the cleaning cost and manpower cost accordingly. How to treat wet waste correctly in condition of low cost and high efficiency is becoming new challenges nowadays.

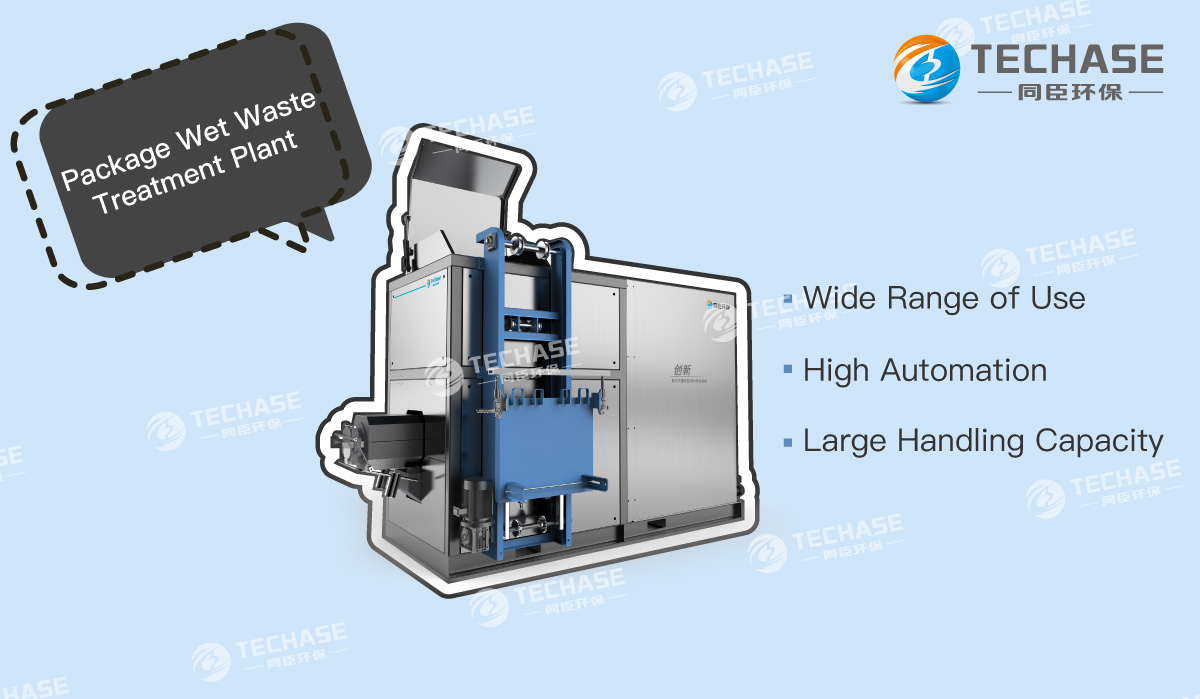

Equipment Profile

The package wet waste has super-high moisture content and organic matter, and the large amount leads to corrupt and produce odor. Given the circumstances, Techase has put out Package Wet Waste Treatment Plant, a machine which can reduce the volume of the wet waste. The garbage volume is reduced by 80-90%, which means there is no need for users to treat it by transportation. By our product, it reduces the pressure of sanitation transportation, and the remaining residue will be collected and transported by sanitation trucks for centralized disposal.

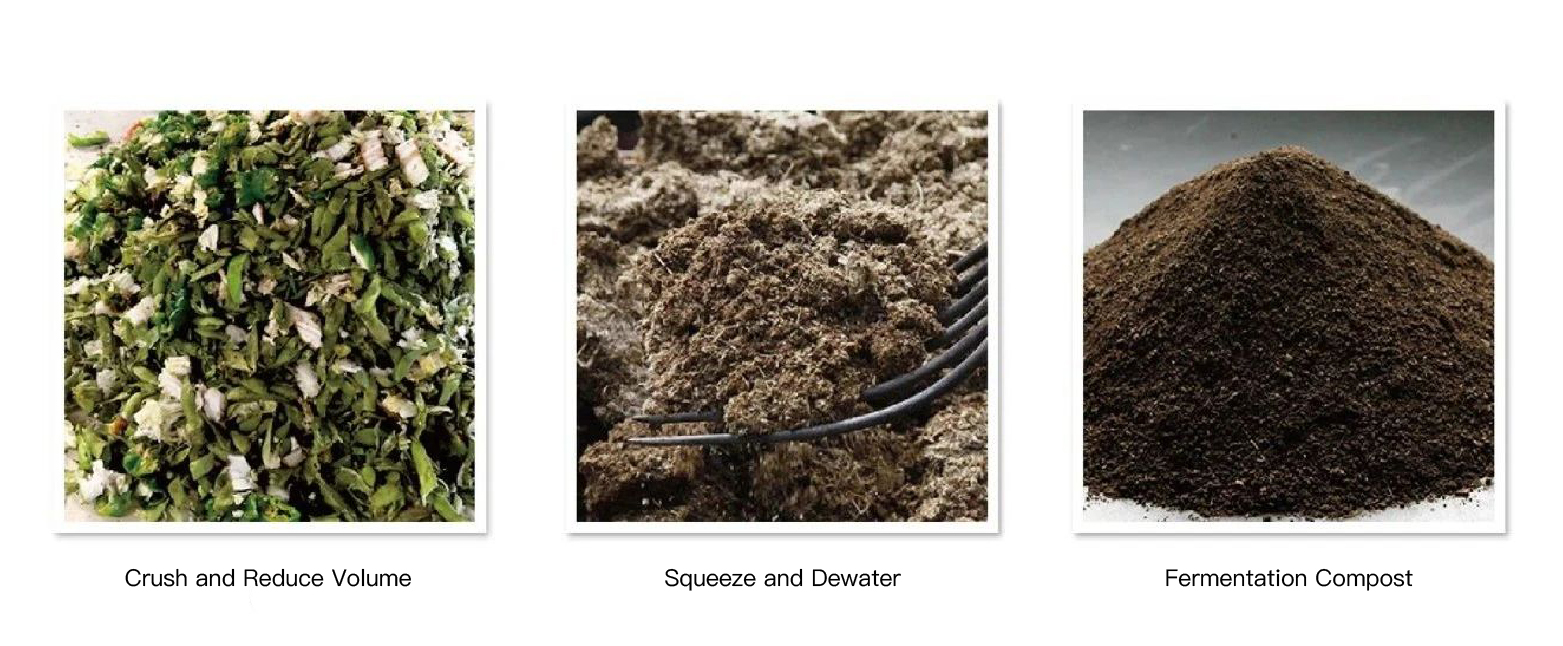

After the treatment, the wet waste is transformed into new resources through biochemical treatment. Due to its high organic content characteristic, it can be used as fertilizer, feed or fuel. What’s more, the oil part can be used to prepare biofuels.

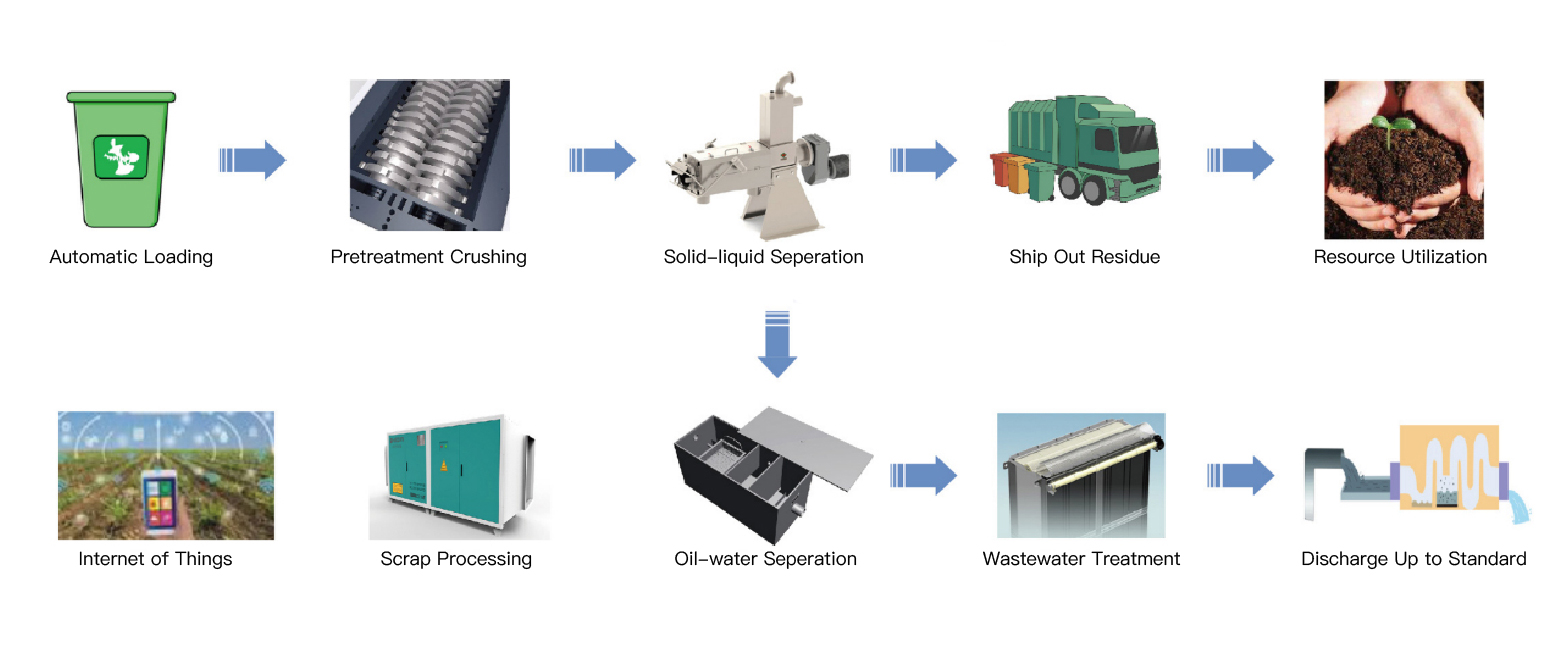

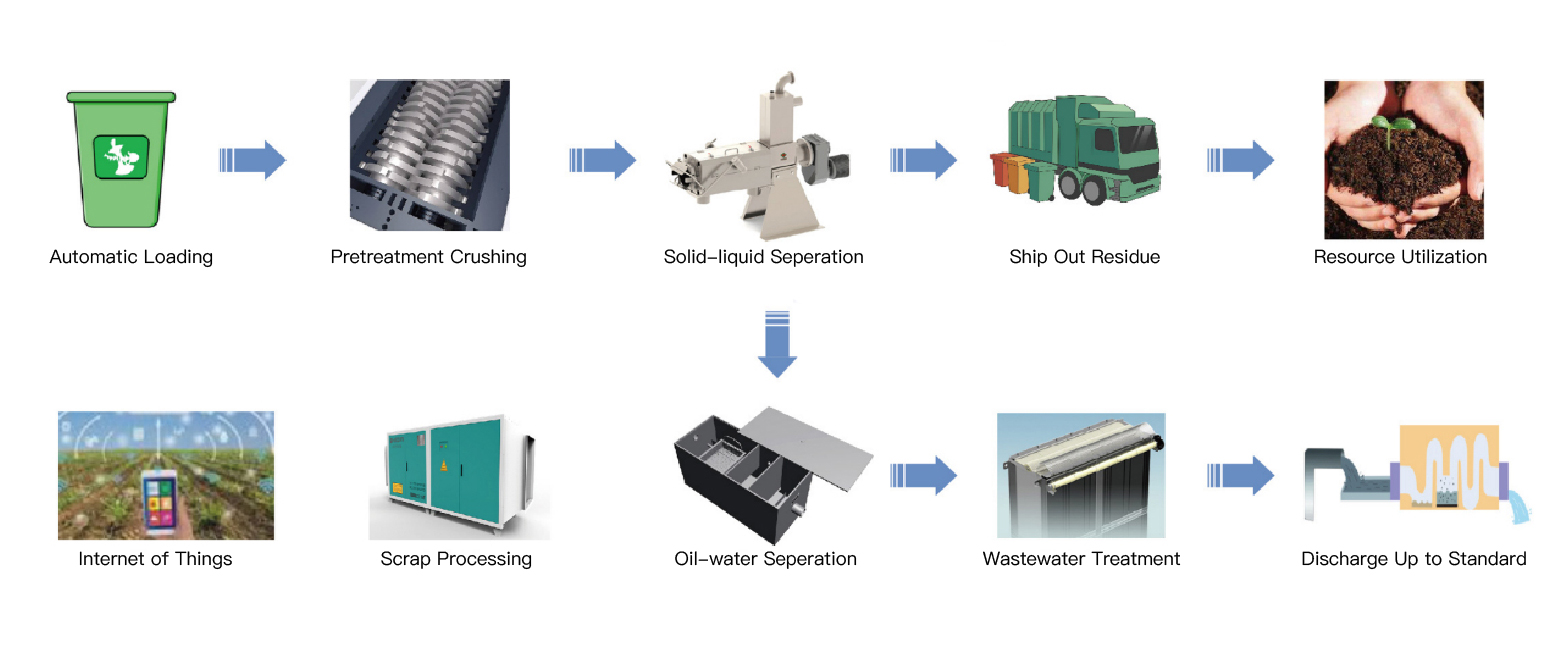

Working Principle

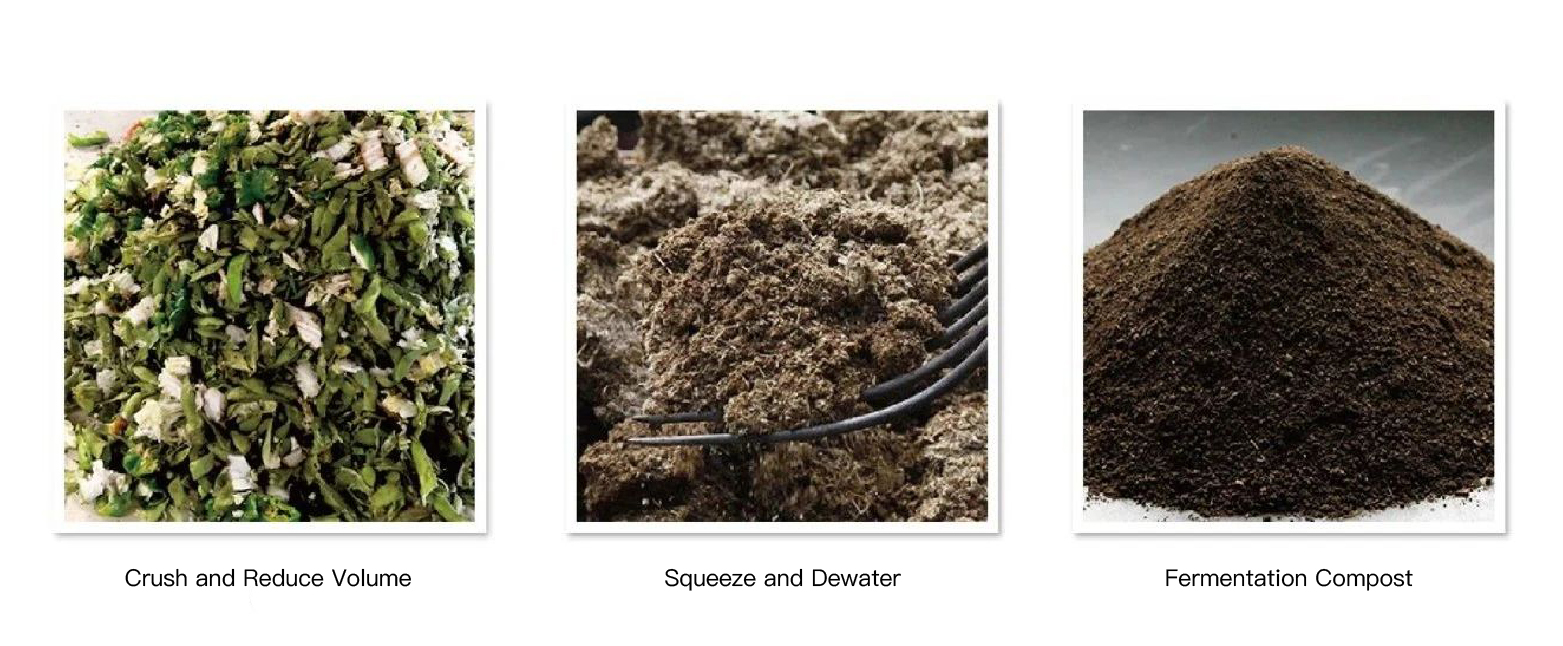

After the worker sorting the wet waste, organic usable waste will be put into dustbins. The package wet waste treatment plant automatically dumps the garbage into the garbage pretreatment crusher by its hoist. The garbage pretreatment crusher is made up of alloy steel blade. The organic waste is crushed to about 5mm by extrusion, shearing and tearing principle. Then the organic waste realizes solid-liquid separation by rotating extrusion in spiral blade transmission line.

The separated wastewater enters the buffer pool and is pumped to the waste water treatment system. The organic components are decomposed. The water with most organic matter removed is filtered through the membrane and then discharged into the urban sewer according to DB 31/199-2018 Comprehensive Sewage Discharge Standard.

The residue produced by the solid-liquid separation unit is collected and transported uniformly, and can be converted into organic fertilizer for recycling after the back-end biochemical treatment.

Equipment Advantages

1.Wide Range of Use

In addition to ordinary fruit and vegetable wastes, some unmanageable materials, such as bamboo shoots, eggshells, hard fruit shells can be treated,too. Garbage volume is reduced by 80%-90%.

2.Little Odor Leaking & No noise

Physical press without odors and fully enclosed design help avoid odor leaking. Low speed rotation and low noise provide a good operation site.

3.Large Handling Capacity, Small Footprint

The Package wet waste treatment plant’s handling capacity is up to 1t/h and it has about 5㎡ footprint. No distributed supporting transfer equipment, make good use of the space.

4.High Automation

PLC automatic control system process is adopted, safe and convenient operation help realize full automation operation.

5.Save Time and Manpower, More Economical

Automatic feeding, no manual assistance for sorting, and no need for water injection to crush materials, the operation cost is less than 10 yuan per day.

The wet waste disposal in the vegetable market is not only the key to urban garbage disposal, but also related to the construction of the urban environment. The new development, Techase package wet waste treatment plant, can treat the wet waste on-site without external transport, as well as the garbage volume is reduced by 80%-90%, which would reduce handling cost and manpower cost and finally achieve the aim of “Reduce On-site”.

扫一扫咨询微信客服

扫一扫咨询微信客服