Sludge, as a product after sewage treatment, is harmful to environment and hard to treat, which is mainly caused by large amount of moisture in it. The moisture not only adds the weight and volume, but also adds the difficulty of sludge treatment.

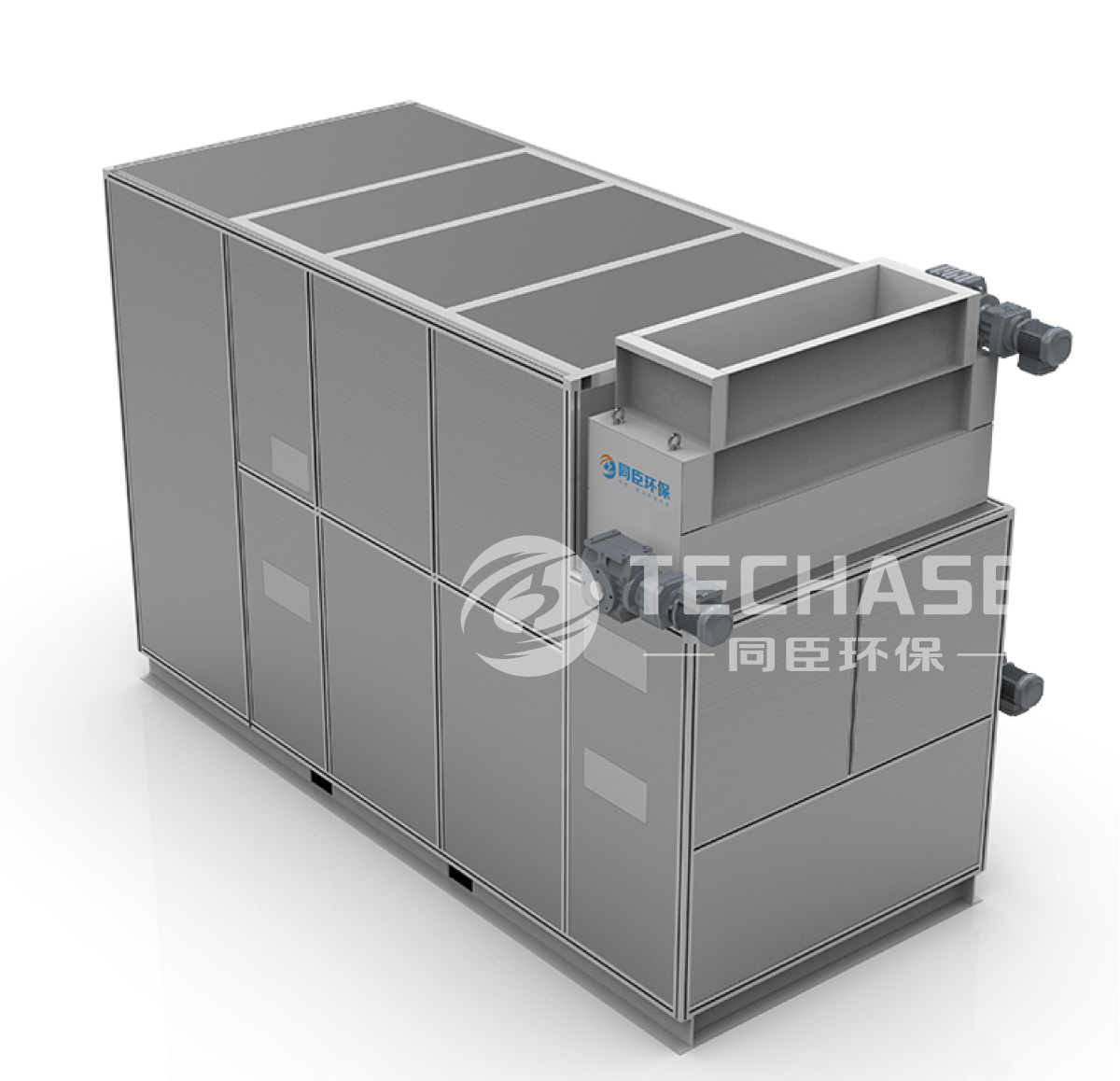

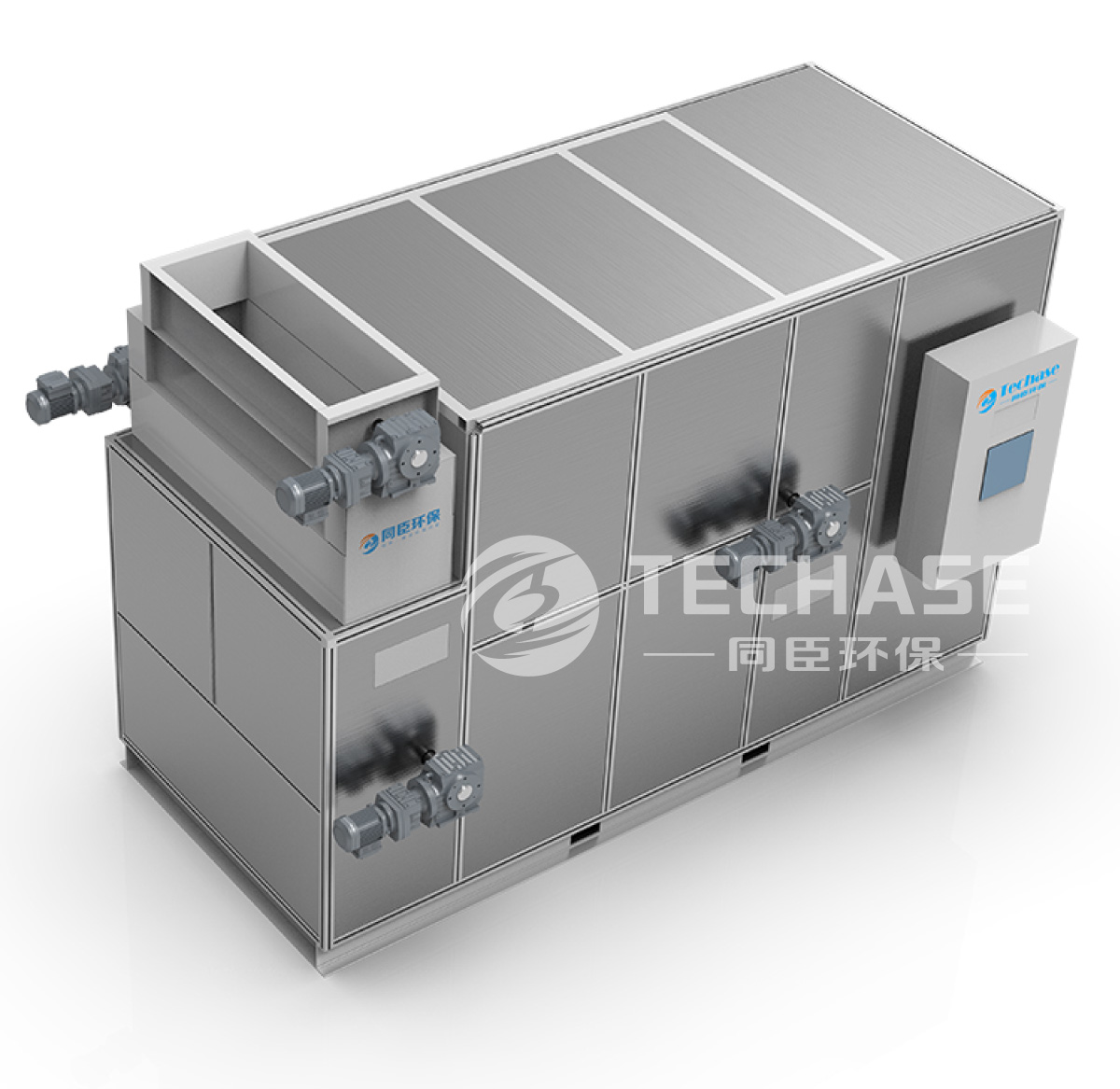

In order to lower the moisture content, Techase is striving for excellence constantly and has launched Low Temperature Sludge Dryer, including Sludge Heat Pump Dryer and Waste Heat Sludge Dryer. The sludge dewatering machine lowers the moisture content by using continuous air to take away the moisture of the sludge. In other words, we can call it “sweating the sludge”. In this way, we can reduce the total weight of the sludge and reduce the treatment cost as well.

So far, Techase Low Temperature Sludge Dryer has been applied to many industries at home and abroad, and widely praised by customers. What makes the customers agree with our product?

01 High Efficiency and Safety, Everybody Praises

As the sludge treatment equipment, the working efficiency is as important as the safe operation. Once handled incorrectly, it’s easy to produce the dust. Moreover, dust explosion also exists in some cases.

Techase Low Temperature Sludge Dryer has strong handling capacity, which can lower the moisture of the sludge from more than 80% to around 10%, and the maximum daily handling capacity can be up to 300 tons. Meanwhile, in order to ensure the using safety, low temperature drying is adopted to treat the sludge. The sludge dry material is granular, thus the possibility of flowing dust and dust explosion caused by sludge dusting can be eliminated.

02 Environmental Protection and Energy Conservation, Great Advantages

As an environmental protection equipment, it lives up to its name. Techase Low Temperature Sludge Dryer doesn’t need to add chemicals. Moreover, the closed drying mode is adopted to avoid odor overflowing, so there is no need to install deodorization device and flue gas treatment device. The energy in the whole drying process is circulatory, so no waste heat will be emitted, low power will be consumed. This makes it possible to minimize operation cost.

03 Easy Operation, High Intelligence

In order to make sure that the equipment can be qualified for its job, Techase Low Temperature Sludge Dryer is designed to be centered on intelligence for convenience. Easy and automatic operation, nobody needs to be on duty, which bring the customers convenient and fast experience.

04 System Integration, Excellent Effect

For better treatment of sludge with higher moisture content, Techase Low Temperature Sludge Dryer can be combined with Techase Multi Plate Screw Press to work together. At first, the Multi Plate Screw Press lowers the moisture content to 80%, and then the Low Temperature Sludge Dryer will dewater further. The whole process is constant and the operation cost and the footprint will be lower, the efficiency will be improved as well.

Project Case

Shandong pharmaceutical company

Sludge Property: Industrial Sludge

Processing Capacity: 15t/d

Energy Consumption: 300kW/t-Water

New Delhi, India Municipal Sludge Drying Project

Sludge Property: Municipal Sludge

Processing Capacity: 2t/d

Processing Effect: Moisture Content from 80% to 30%

When Techase Low Temperature Sludge Dryer was pushed out, it worked well in different industries with these four “secrets” and became the common choice of many customers with no doubt. In the future, Techase will continue to base on the field of sludge and sewage treatment to make greater contributions for environmental protection!

扫一扫咨询微信客服

扫一扫咨询微信客服