Why is canned cola tastier than bottled cola? Firstly, because of the different materials used, canned cola has a higher carbon dioxide content compared to bottled cola. Additionally, cans are sealed and opaque, effectively blocking light to maintain stable carbon dioxide levels. Furthermore, cans are smaller in volume, making consumption quicker and more convenient, while preserving consistent taste. Therefore, in terms of carbon dioxide content and taste, canned cola is generally preferred over bottled cola.

In our daily lives, canned products are ubiquitous, and the demand for canned goods continues to grow. It is understood that each year, China's can manufacturing companies produce an astonishing number of cans, typically in the billions. The vigorous market demand has driven rapid product development but has also brought pollution issues. For example, how to handle the wastewater generated during the can manufacturing process? In this issue, we analyze a case study from the can manufacturing industry on wastewater treatment.

Can-making wastewater mainly comes from the stretching and can-washing processes during production. The wastewater contains high levels of suspended solids, fluorides, as well as some petroleum-based and surfactant components. It has poor biodegradability, high fluoride concentration, and significant fluctuations in water quality, posing considerable challenges for wastewater treatment.

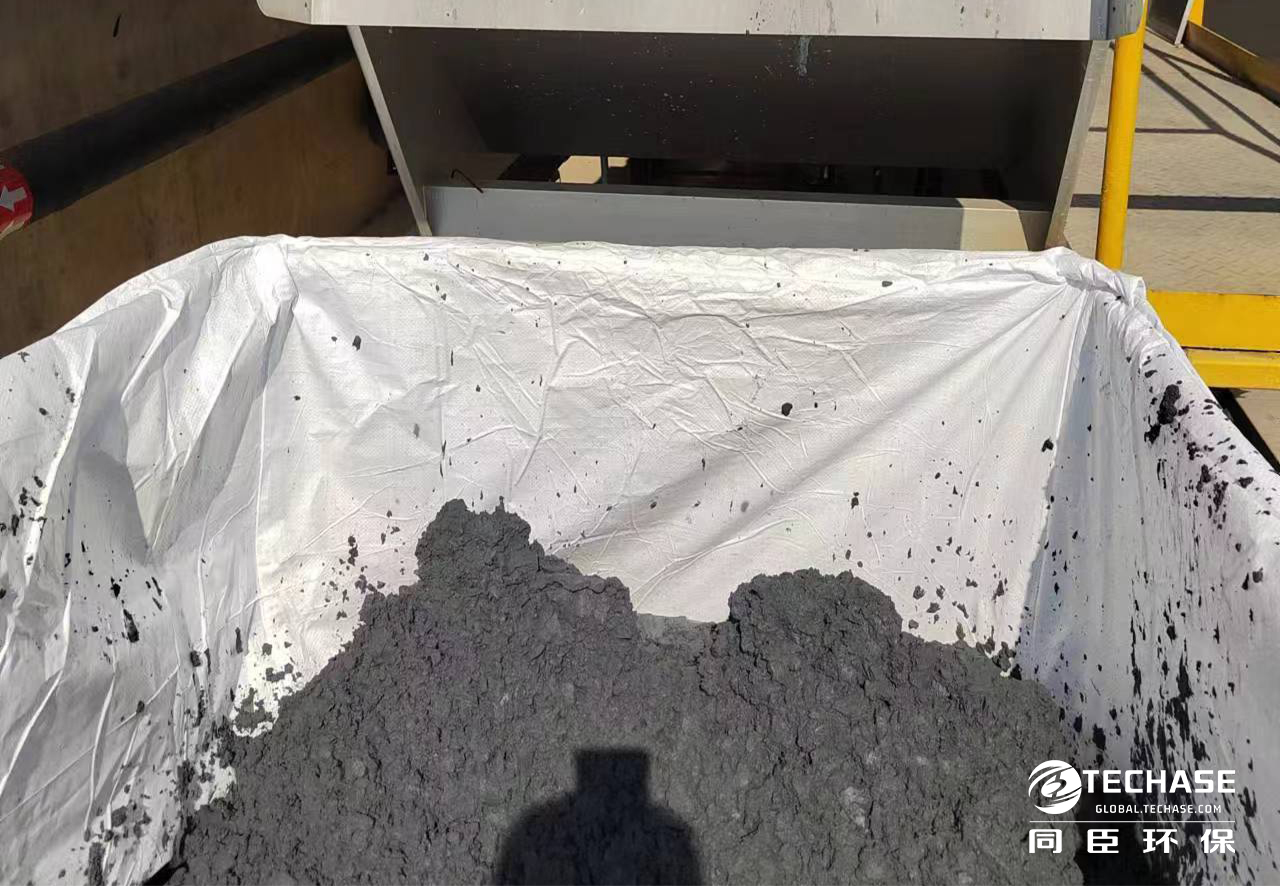

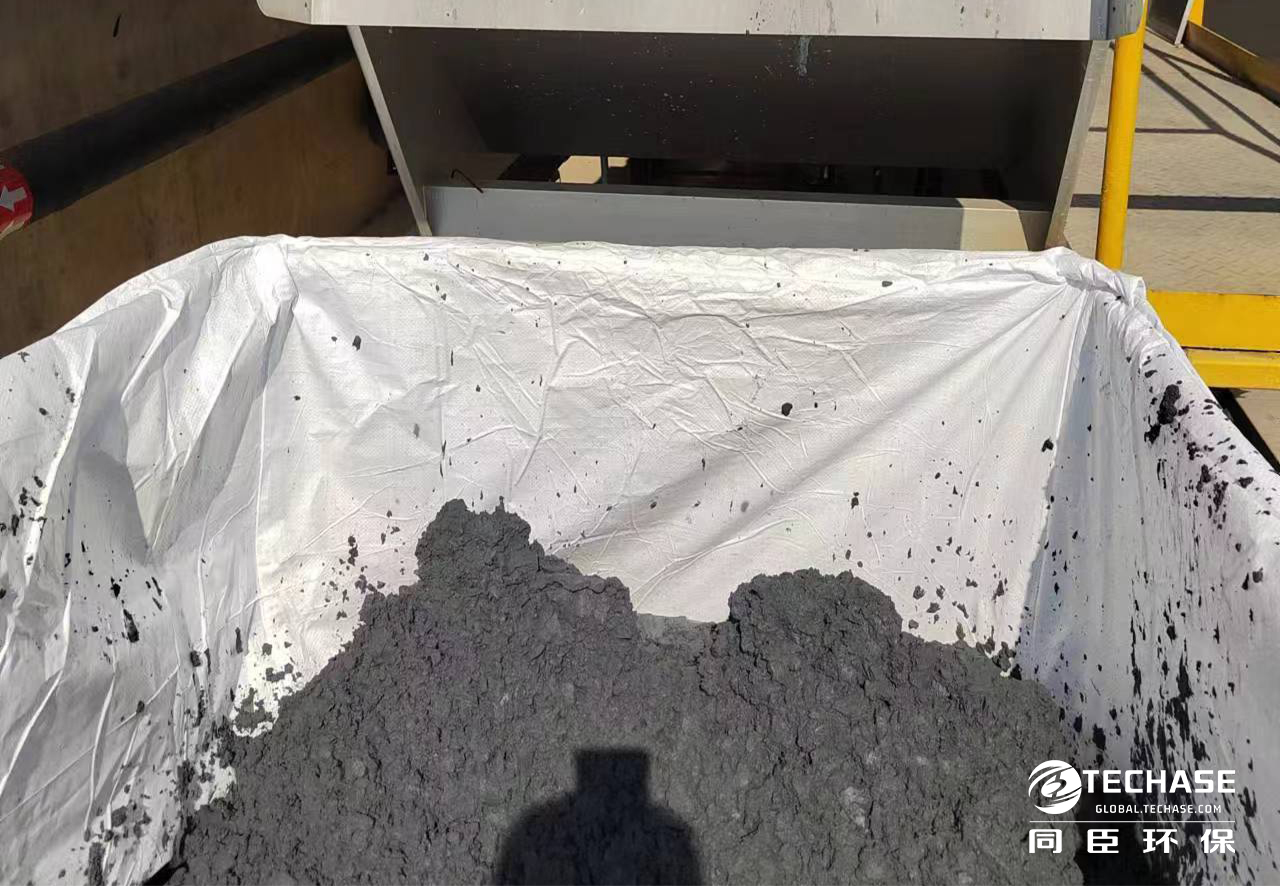

This case involves a wastewater treatment project at a can manufacturing enterprise in Taizhou. The sludge dewatering stage of the factory's wastewater is addressed, utilizing TECHASE Model 302 multi plate screw press and related polymer making & dosing equipment. Initially, sludge from the sludge tank is pumped to the screw press, where polymer is added via the dosing pump for conditioning. After dewatering by the screw press, the moisture content of the sludge is reduced to 80%, and it is finally transported off-site for disposal.

Through the multi plate screw press sludge dewatering system processing, the problem of on-site sludge treatment has been resolved, reducing the operational costs of the end users and improving resource utilization rates. This achievement has been highly praised and recognized by the clients.

The device has the following advantages:

1. Fully automatic operation, continuous feeding and discharging, no need for manual duty, can achieve remote one click start stop, operation is worry free and labor-saving.

2. Energy saving and low operating costs. The rotating speed of the screws is only 2-4r/min, and the power of a single screw is less than 5kW. Averagely, the energy consumption is about 1/8 of belt filter presses and 1/20 of that of decanter centrifuges.

3. CFRP rings have excellent wear resistance, a 2-year replacement rate of less than 5%, a service life more than twice that of traditional stainless steel 304 rings, and lower maintenance costs.

4. CFRP rings do not react with acids, alkalis, and salts, thus effectively utilizing their high-quality corrosion resistance. Compared with 316 or even duplex steel rings, the use of CFRP rings not only improves product performance but also significantly reduces investment costs.

5. Screws overlay welding with ultra wear-resistant hard alloy layer, its overlay welding thickness is 100-150 times that of ordinary spraying process, greatly extending the service life of equipment and reducing maintenance frequency.

In the future, Techase will continue to explore and deeply cultivate different industry fields, with a pioneering spirit of innovation and continuous progress, and a development philosophy of quality first and service first, to solve environmental problems for the vast number of users.

扫一扫咨询微信客服

扫一扫咨询微信客服