Sludge, as a by-product of sewage treatment, has complex components and a pungent smell. In addition to the original odor of sludge components, under anaerobic conditions, highly irritating and corrosive harmful gases such as ammonia and hydrogen sulfide may also be produced.

Below are some proposals for effective measures of odor control in low-temperature drying workshops for reference.

1. Keep “fresh” sludge for drying

The so-called "fresh" mainly means that the wet sludge to be dried should not be stored for too long. The wet sludge here includes two types, namely the original sludge from the front-end sludge tank and the sludge from mechanical dehydration. After preliminary dehydration, the sludge should inlet the low-temperature dryer as soon as possible to achieve daily cleanliness. Otherwise, the longer the wet sludge is stored, the more odorous gas will be produced.

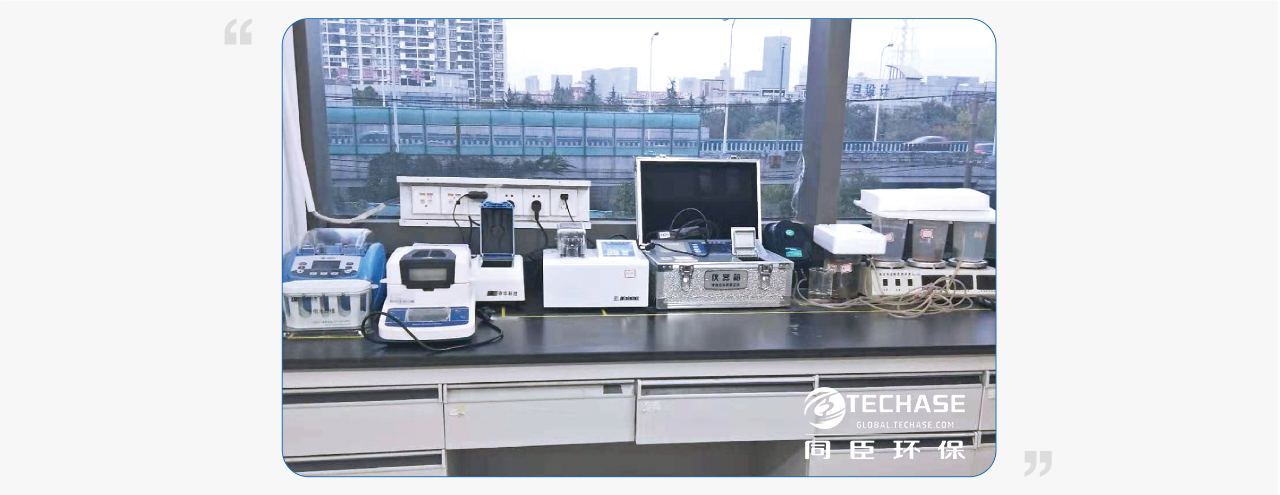

2. Regularly monitor the gas

The composition and content of malodorous gases need to be effectively monitored. Based on the monitored data, the circulating air inside the dryer is updated in a timely manner to ensure that the content of polluting gases is in a lower range.

3. Wet dust removal to recommend

At present, the dust removal technology inside the dryer is generally divided into dry dust removal and wet dust removal. Ammonia, hydrogen sulfide and other gases are with good water solubility. We prefer to use wet film dust removal technology. Wet film dust removal technology is a brand-new dust removal process that can not only effectively remove dust in circulating air, but also effectively absorb volatile gases in circulating air, effectively inhibiting the spread of odors.

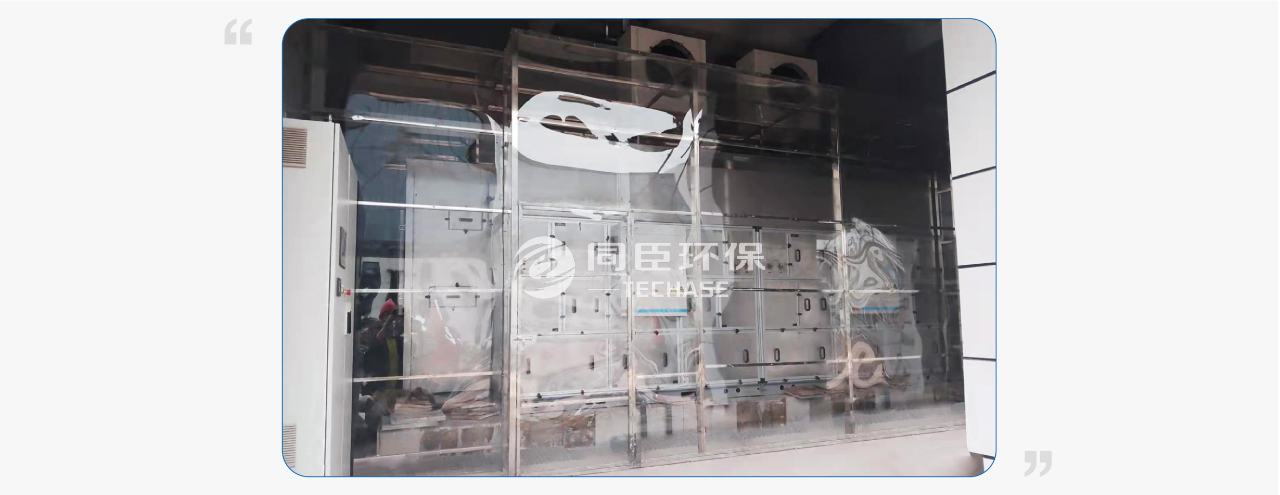

4. Odor proof and leak proof

It is suggested to use the drying equipment with an integrated structure and reduce the number of assembly joints. In addition, sealing measures for access doors, access windows, sludge inlets and sludge outlets are also critical. The better airtightness of the dryer, the lower risk of odor leakage; the less frequently the device is opened, the less amount of odor leakage will be. When the workshop has a deodorizing design, exhaust vents can be installed at the inlet and outlet of the dryer, or the outside of the dryer can be sealed as a whole to create a truly odorless drying workshop.

扫一扫咨询微信客服

扫一扫咨询微信客服