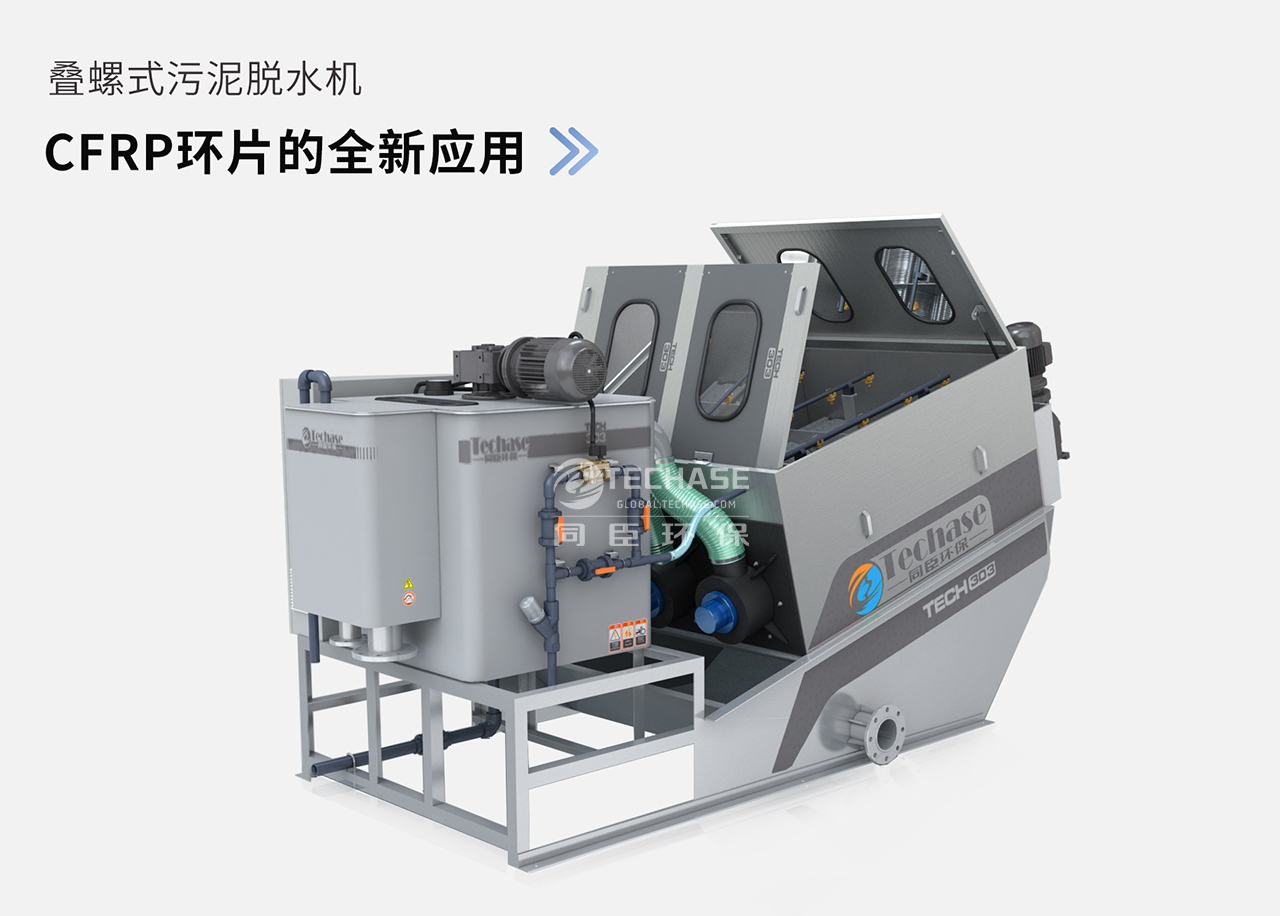

As an advanced sludge dewatering equipment, the screw press has already occupied a place in the market. As one of the core components of the screw press, the moving and fixed ring plays a crucial role in the operation of the screw press.

However, there are some problems that cannot be ignored in using traditional stainless steel 304 ring plate: the wear rate of stainless steel ring plates is fast, which further exacerbates the corrosion rate of the ring plates.

In order to solve these problems, TeChase has successfully applied the carbon fiber reinforced composite material (CFRP), known as the "king of new materials". Its lightweight, high-strength, wear-resistant, corrosion-resistant and other superior properties bring screw press with shorter production cycle, longer service life, and more convenient maintenance methods.

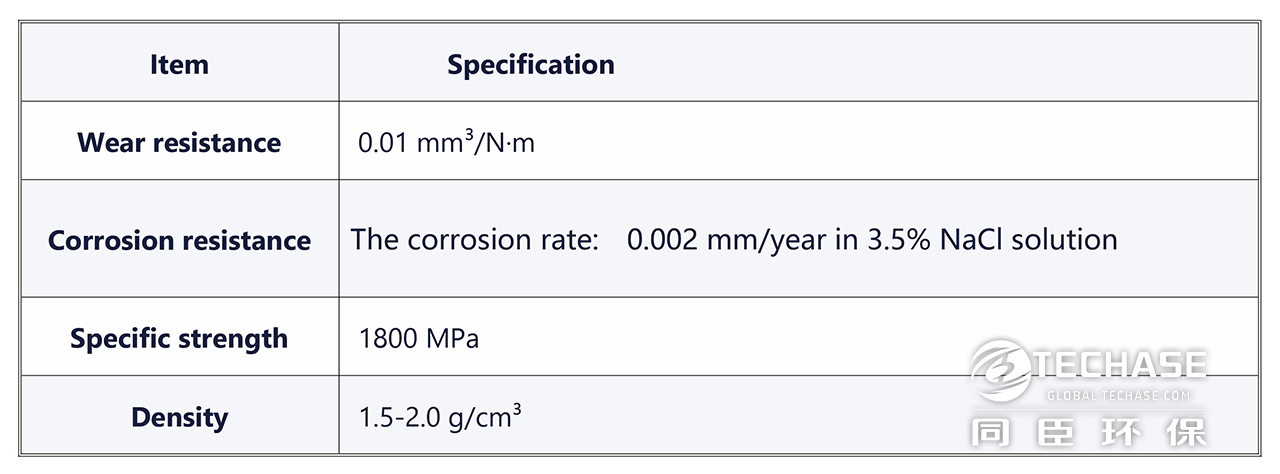

Specification of CFRP ring

The application of CFRP in other industrial manufacturing fields

Carbon fiber reinforced composite materials (CFRP) are becoming an ideal choice for industrial manufacturing due to their unique advantages. The following are some typical applications of CFRP in industrial manufacturing:

(1) Automobile manufacturing

Automotive manufacturing is an important field for the application of CFRP. Due to the lightweight, high strength, and corrosion resistance characteristics of CFRP, automobile manufacturers are increasingly using CFRP materials to manufacture the outer shell and internal structure of automobiles. It not only improves the performance and safety of automobiles, but also reduces their energy consumption and emissions.

(2) Aerospace

The aerospace industry has extremely high requirements for materials, and CFRP materials are widely used in the shells, internal structures, and components of aircraft and rockets. The lightweight and high-strength characteristics of CFRP help improve the performance of aerospace vehicles, reduce energy consumption, reduce weight, and improve safety.

(3) New energy equipment

New energy equipment also has high requirements for lightweight and high-strength materials. The brackets and blades of solar panels and wind power generation equipment are made of CFRP material. The use of CFRP materials in solar panels and wind power generation equipment can improve energy efficiency, reduce costs, and extend service life.

As a manufacturer specializing in sludge dewatering equipment, TeChase is well aware of the importance of material selection for product quality and performance. Through continuous innovation and improvement, CFRP material is used for the ring of screw press, to achieve short service life and high replacement frequency. This innovation has led the industry to progress, making the screw press more efficient in practical applications.

扫一扫咨询微信客服

扫一扫咨询微信客服