Techase Case Sharing

Techase low temperature sludge dryer

Aikewei Wastewater Treatment Project

Speaking of Huai'an, in addition to the ancient cultural charm with a long history, there are also outstanding mountains and rivers. Prosperous because of luck, prosperous because of luck. Abundant river and lake resources are everywhere here, and the emerging industrial economy is advancing by leaps and bounds, especially the industrial system dominated by the three hundred billion industries of special steel, electronic information and new chemical materials. This Huai'an project is one of Techase's sludge drying projects in the chemical industry.

Project Introduction

Project Introduction

The company to which the project belongs is a high-tech company engaged in research and development, consulting, production and sales of fine chemical technology. This project is mainly aimed at the second-stage sewage treatment transformation of the plant area. The daily processing volume of absolute dry sludge is 450kg/d, and the type of sludge is chemical sludge. As we all know, chemical sludge usually has a complex composition, containing a large number of drugs and different kinds of heavy metals. According to the national and local environmental protection regulations, the latest standards must be strictly followed to ensure that the on-site sludge disposal meets environmental requirements. The project adopts the Techase® multi plate screw press+sludge low-temperature drying process. The moisture content of the sludge cake after sludge drying is 15% (adjustable), and the daily weight loss of the system exceeds 55 tons.

Scan and identify the QR code, you can view the project site 360°!

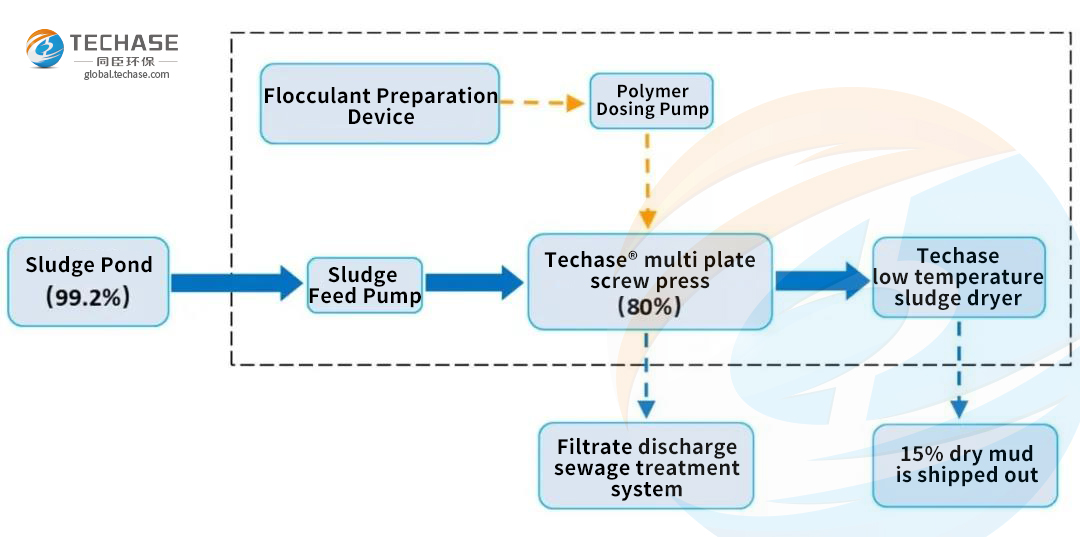

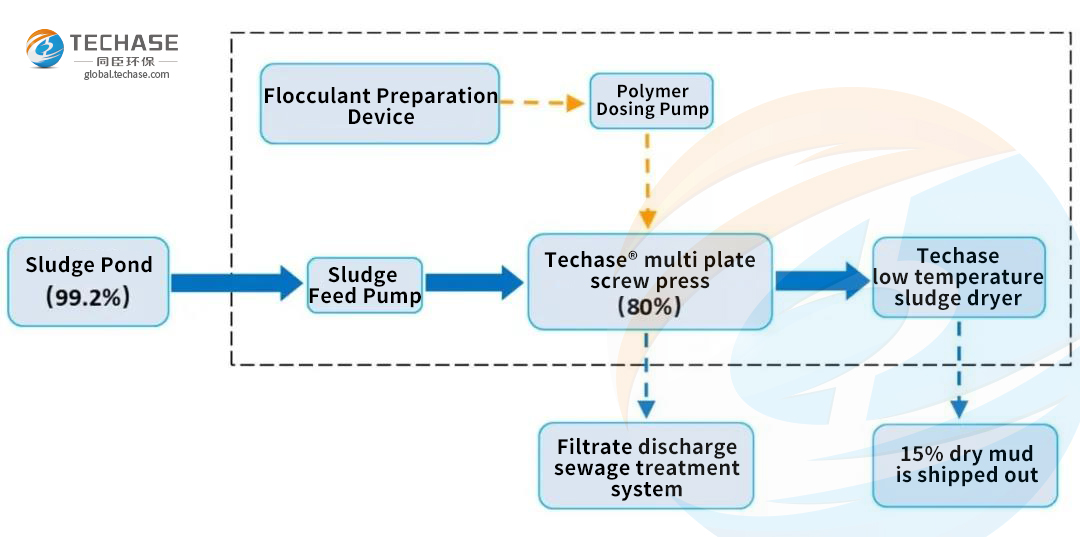

Process Flow

The project selected TECH-301 Techase® multi plate screw press+TCSD2400AC Techase low temperature sludge dryer and other related supporting equipment. First, the sludge to be processed (water content 99.2%) is delivered to Techase® multi plate screw press through the mud pump, and after the flocculation and conditioning of the sludge is completed in the flocculation mixing tank, the concentration and dehydration of the sludge starts; the moisture content of the sludge after dehydration is 80%; Transported to the Techase low temperature sludge dryer, crushed and granulated, and then dried. The moisture content of the dried sludge is 15% (adjustable). The dried mud is transported by the screw conveyor to the dried sludge storage bin for temporary storage, and then directly loaded. Disposal of out-of-vehicle transportation.

The condensate produced during the drying process of the filtrate and Techase low temperature sludge dryer from the Techase® multi plate screw press needs to be returned to the sewage treatment system for reprocessing.

Process Advantage

Process Advantage

1. Stable sludge with low moisture content, 15% moisture content (adjustable), dry sludge in granular form, no danger of dust explosion;

2. The whole process does not need to add iron salt, aluminum salt and lime and other conditioning agents, which is environmentally friendly and is conducive to later resource utilization;

3. Achieve fully automatic operation, no need to be on-site on-site, reducing labor costs in the factory area;

4. The combination of Techase screw pres+Techase low temperature sludge dryer system has a small area and high drying efficiency;

5. High-performance material and structure design, the system is stable and reliable, and has a long service life;

With the corresponding implementation and popularization of environmental protection policies, major industries have higher requirements for the treatment and disposal of sludge. In the face of more severe environmental challenges, Techase will continue to innovate, create brand-new environmental protection equipment and services with more exquisite and more systematic processes and technologies, enhance the technical strength of the company, and continue to work hard for the construction of green environmental energy!

扫一扫咨询微信客服

扫一扫咨询微信客服