This time, let me take you to Lingbi, Anhui, China to know more about Techase “80% sludge feeding directly” process.

Conventional deep sludge dewatering projects generally need to control sludge MC at about 95%, and then start the final squeezing stage for deep dewatering. In this way, some sludge with 80% MC has to be diluted first which is more complex and expensive.

Techase has applicated “80% MC Sludge Feeding Directly” process into Lingbi WWTP, which could be connected to existing sludge dewatering machine to treat the 80% MC sludge and simplify deep sludge dewatering process and save operation and investment cost to some extent.

Project Overview

Lingbi WWTP is a wastewater treatment facility construction project adopted by the government in PPP mode. The project covers an area of about 55 mu, and the designed wastewater treatment capacity is 20,000 m³/d. The process adopts pretreatment +A²O+ advanced treatment + disinfection process. The sludge deep dewatering system adopts Techase "80% sludge feeding directly" process, the effluent is in accordance with the Level A discharge standard of Pollutant Discharge Standard for Urban Wastewater Treatment Plant (GB18918-2002), and the tail water is discharged to the Yan River.

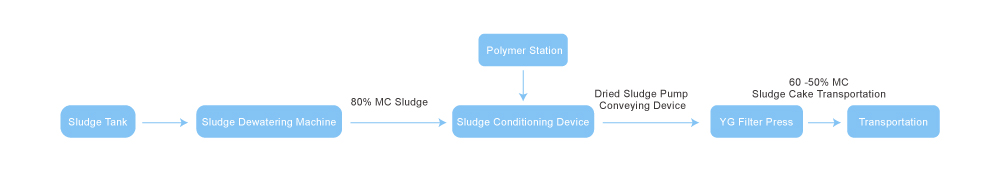

Process Flow

The whole system of Lingbi WWTP adopts Techase’ volute sludge dewatering machine – multi plate screw press, YG series super high pressure filter press and related supporting equipment. First of all, the sludge is transferred from the sludge pool to techase multi plate screw press for primary dewatering treatment, and the moisture content of the dehydrated sludge cake is 80%. Then the sludge cake is transported to the sludge conditioning machine for conditioning, and the chemicals are automatically added to the conditioning machine through the automatic dosing machine. After conditioning, the sludge is collected in the sludge cache hopper, and then it is directly transported to the YG series super high pressure press through the dried sludge cake pump conveying device for pressing and dewatering. The moisture content of the final output sludge cake is 58%. Finally, The conveyor belt conveys the sludge cake to thetruck for outward transport and disposal.

Technical Advantages

1.80% MC Sludge Feeding Directly, Simple Technology, Low Operation Cost

It can be seamlessly connected with the existing sludge dewatering equipment in the sewage plant, on the basis of the original equipment, the sludge with 80% moisture content is directly fed into the equipment, and the original deep dewatering process of dilution and conditioning is changed.The whole process is simple and the operation cost is low.

2. Fast and High Efficient, System operation efficiency is increased by 40%

Techase adopts the new process to effectively shorten the single batch running time of YG filter press, the core equipment of deep stripping, and improves the system running efficiency by about 40%.

3. Good Performance, Stable Final Output Sludge Cake

YG Filter Press has great structure strength and it can adapt 80% MC sludge feeding

directly which cannot be treated by membrane filter press. Finally, the deep sludge dewatering can be realized with good effect and the moisture content of final output sludge cake can be in the range of 60%-50%.

Techase new application at Lingbi WWTP could not only help solve the problem of sludge treatment, but also carry on the breakthrough reform in the technological process and change the original deep sludge dewatering technology (dilute → condition). The whole process is simple, which could reduce operation cost and finally achieve the aim of sludge reduction and recycling.

扫一扫咨询微信客服

扫一扫咨询微信客服