Sludge drying treatment, as a crucial means of achieving resource regeneration, is not only a necessary measure for sludge reduction, harmlessness, and resource utilization but also holds broad application prospects and practical significance. Currently, sludge disposal has various applications, such as land use, incineration, landfill, building materials, and fertilizers. These methods not only reduce sludge accumulation and environmental pollution but also realize resource reuse, contributing significantly to ecological environment construction.

As is well known, sludge comes in many forms. When considering resource utilization, the choice of disposal methods should be both economical and efficient, based on the distinct properties of the sludge. In this case, as part of the TEC-HASE case tour across China, we visited a tunnel kiln brick factory in Jiangsu Province to explore the practical application of TEC-HASE drying technology in utilizing sludge for building materials.

The project processes municipal sludge with a moisture content of approximately 70%. Due to the high moisture content, drying and dewatering are required. The low-temperature dryer produced by TEC-HASE, which operates entirely on waste heat, uses the waste flue gas from the factory's existing kiln as the heat source, eliminating the need for steam consumption. By adopting a single-stage heat exchange design, the waste heat is directly utilized by the equipment, significantly reducing drying costs to as low as 30 RMB per ton of sludge. After drying, the sludge's moisture content is reduced to below 30% and is further processed into brick and tile products for sale, achieving resource utilization of the sludge.

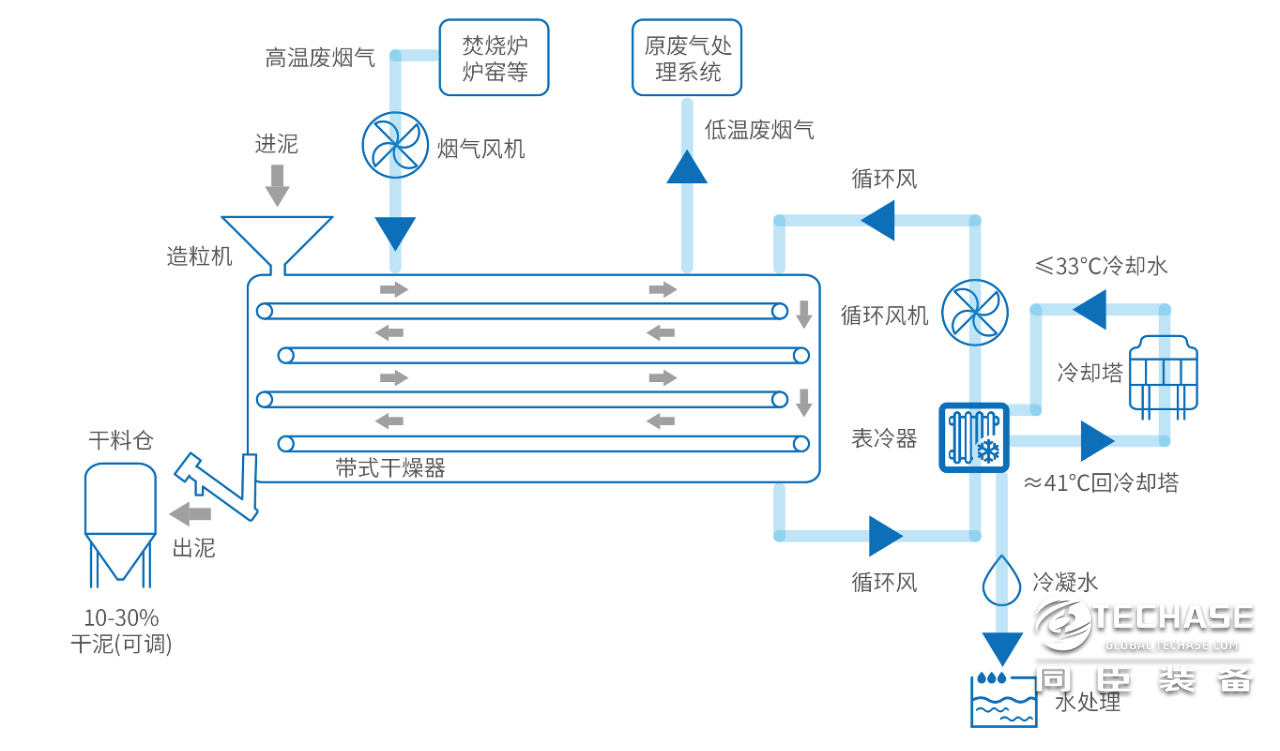

technological process:

The sludge is transported to the dryer for uniform spreading, and the waste heat (waste gas, cooling air, etc.) generated during the production process is utilized to provide heat for drying in the dryer. The water in the sludge evaporates rapidly and is discharged from the drying equipment after condensation. After drying, the moisture content of the sludge can be reduced to 10% -30%.

Technological advantages:

1、Treating waste with waste: fully utilizing waste heat for drying, promoting energy savings and carbon reduction.

2、Multi-layer spreading and wet film dust removal for intelligent production.

3、Simple process, small investment and space requirements, and low operating costs.

4、Thorough volume reduction, fast investment recovery, and significant economic benefits.

5、Independent system with high compatibility, suitable for a wide range of applications.

The actual operation results show that the Techase Full Waste Heat Low Temperature Drying Machine treatment system has high production efficiency, good operating conditions, and has been highly praised by users. Its characteristics such as stable sludge discharge, low operating costs, and intelligent automation not only meet the high requirements of users for product performance and stability, but also bring significant economic and environmental benefits to users.

扫一扫咨询微信客服

扫一扫咨询微信客服