Jiangxi, a place of cultural heritage and a land of literary refinement, has nurtured various distinctive cultures such as red culture, landscape culture, and ceramic culture. Here, the development of a long history, profound cultural deposits, unique natural landscapes, and rich red culture, add to the unique cultural charm of Jiangxi. This national "trip" of the Techase case brought us to the beautiful scenery of Jiangxi. The low temperature drying project of the large-scale sludge centralized disposal center with a processing capacity of 350 tons/day, how is the site situation, let's see!

Project Overview

The large-scale sludge centralized disposal center in Jiangxi has a construction scale of 350 tons/day. As a centralized disposal center, the types of sludge vary, including 150 tons/day of kitchen waste, 150 tons/day of sludge from domestic sewage treatment plants, and 50 tons/day of kitchen waste. The dehydration process adopts centrifuge+dryer, and uses two TCSD60000 TECHASE Dust Free Low-Temperature Multi-Belt Dryer TD. After drying, the moisture content of the sludge is 30%, and it is finally packaged and transported for resource utilization.

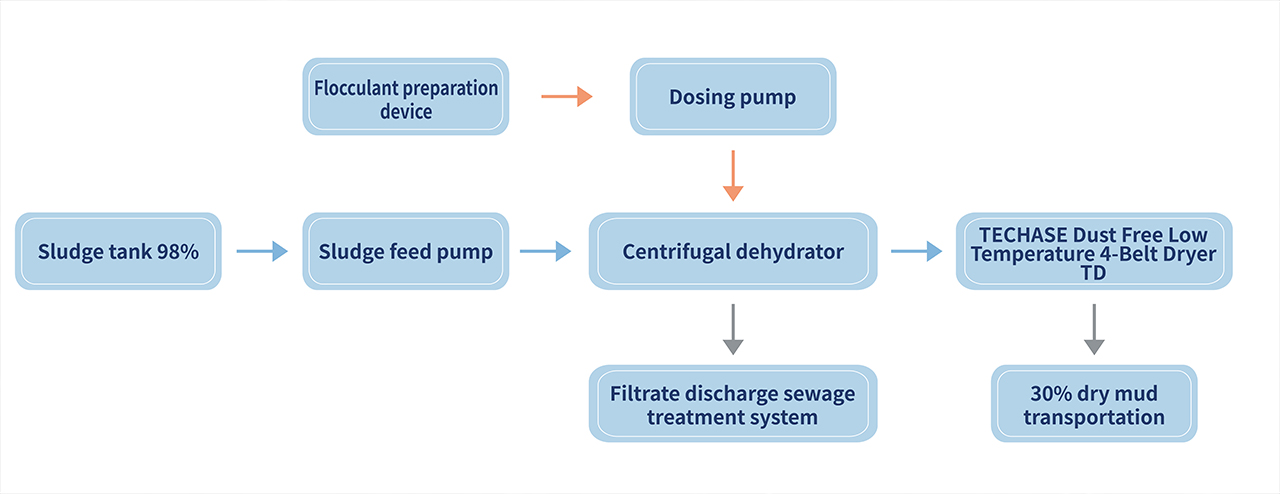

Process Flow Diagram

Process route description

The centrifugal dehydrator is mainly composed of a rotary drum, spiral conveyor with hollow shaft rotation, differential and other main components. The sludge is fed into the material system by the pipe after mixing, and the screw conveyor pushes the sludge through the cylinder part of the drum to the spiral cone at a speed greater than the rotating drum. Under the centrifugal force generated by high-speed rotation, the sludge is continuously dewatered. After dehydration, the sludge cake is formed, which enters the low temperature dryer for drying. The filtrate and condensed water from the dryer are collected and discharged back to the sewage treatment system for treatment.

Principle of Drying Machine

The dehydrated sludge is fed in low temperature sludge dryer after granulation, then the sludge is distributed evenly on the conveying track by sludge arranged distributor so that the moisture can be taken away by flowing air provided by circulating blower and finally realized discharge of the dry sludge; The flow of hot dry air increases the evaporation rate of water in the sludge. After the moisture taken away by the flowing air, the air is condensed at the condenser, the condensed liquid is discharged out of the equipment, and the dry air is reheated by the heater, then reenter into the sludge, and cycling in this way.

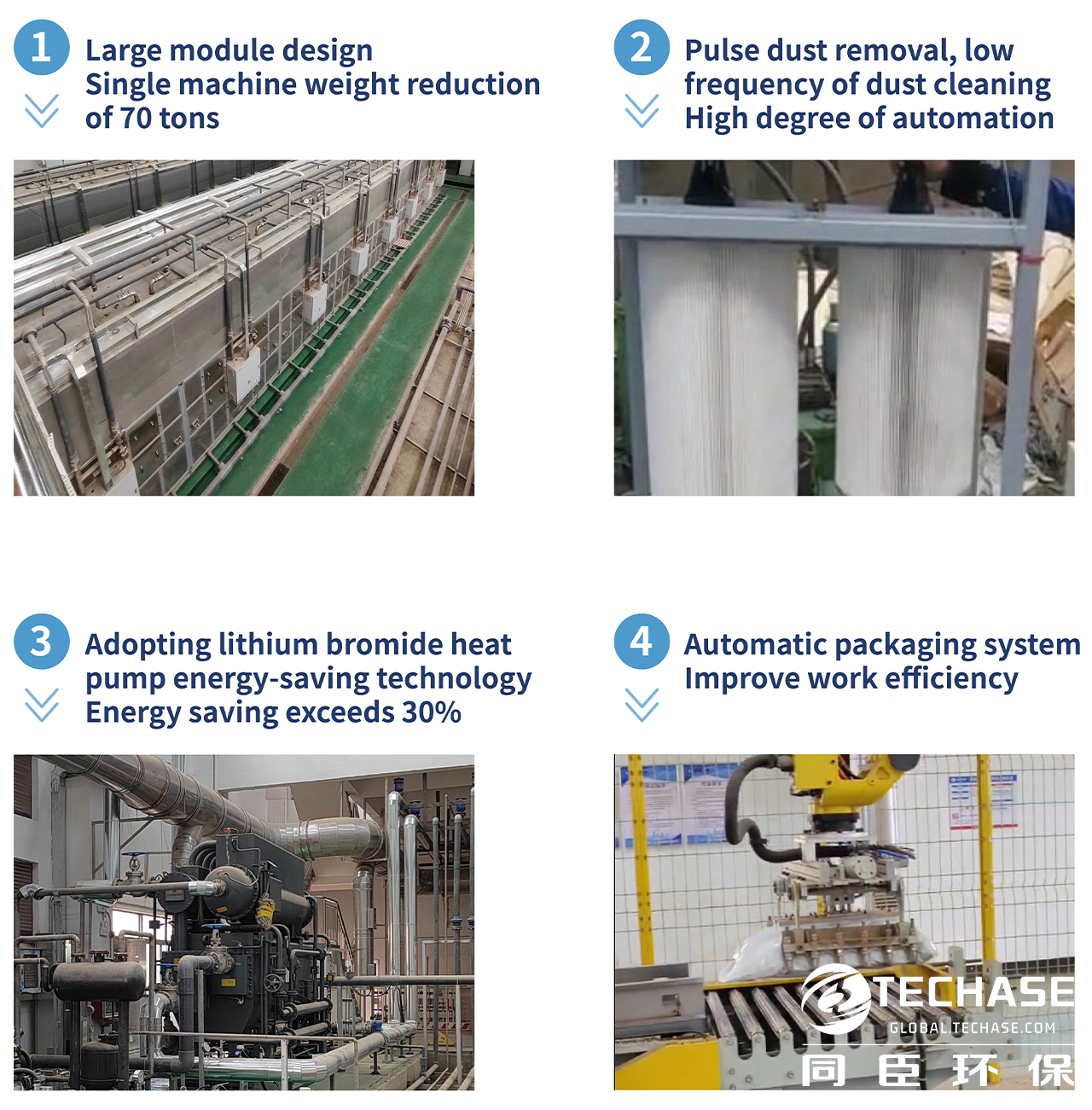

Project Feature Description

Since the operation of the project, with its excellent performance and high-quality and stable operation effect, it has not only achieved its established goals perfectly, but also brought significant economic and environmental benefits to the client. So far, TECHASE Dust Free Low-Temperature Multi-Belt Dryer TD has been widely used in industries such as municipal, pharmaceutical, chemical, food, semiconductor, electroplating, new energy, printing and dyeing, and papermaking!

In the future, Techase will continue to innovate, strive tirelessly, optimize product structure, improve service quality, ensure that every product and project exceeds customer expectations, and bring customers a good user experience and product benefits. While solving environmental problems for users, we continuously strive for green and sustainable development of the environment!

扫一扫咨询微信客服

扫一扫咨询微信客服