landfill leachate

Technology and Case

With the rapid development of the urban economy and the steady improvement of people's living standards, the output of domestic waste in my country is increasing day by day, and the amount of waste treated is also increasing year by year. With the continuous changes in environmental protection policies, the main treatment method of domestic waste has gradually shifted from landfill to waste incineration. It is reported that since 2019, the proportion of waste incineration has surpassed that of landfill, 50.70% and 45.59% respectively. Comprehensive forward-looking estimates, domestic waste incineration will show a continuous growth trend.

At present, my country's garbage classification mechanism is not perfect, and the water content of domestic garbage has always been high, above 50%. And these huge quantities of domestic waste will produce a large amount of landfill leachate during the treatment process, which contains high levels of organic toxic substances, heavy metal ions, bacteria and viruses, etc. Once it seeps out, it will cause serious pollution to the environment. Therefore, in order to protect the environment, the treatment of landfill leachate is imperative and crucial!

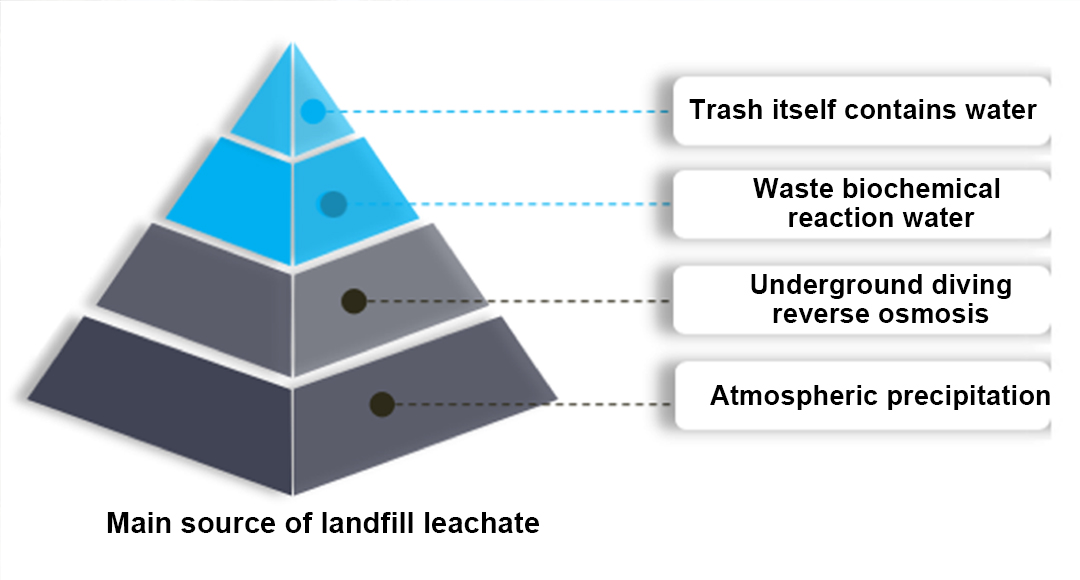

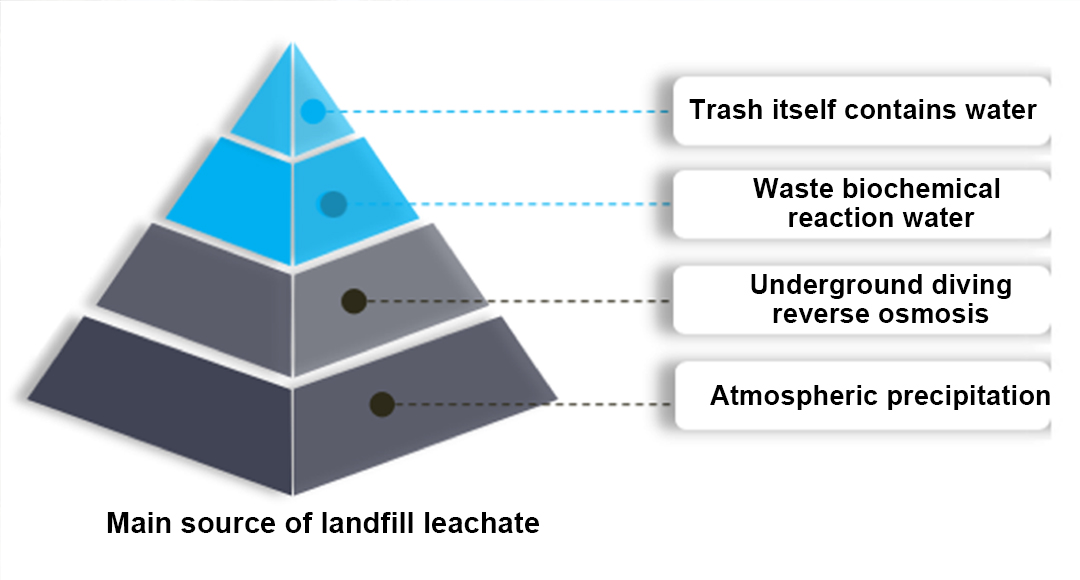

There are four main sources of landfill leachate: the water contained in the garbage itself, the water produced by the biochemical reaction of the garbage, the reverse osmosis of underground diving, and atmospheric precipitation. Among them, atmospheric precipitation is concentrated, short-term and repetitive, accounting for the total amount of leachate. the most part of. As a high-concentration organic wastewater with complex components, landfill leachate is different from ordinary urban sewage. It has complex and harmful water quality, high BOD5 and COD concentrations, high metal content, large changes in water quality and water quality, and high ammonia nitrogen content. The proportion of microbial nutrients is imbalanced and other characteristics. If these large amounts of landfill leachate are directly discharged into the environment without treatment, they will cause serious pollution to the surrounding water bodies and soil.

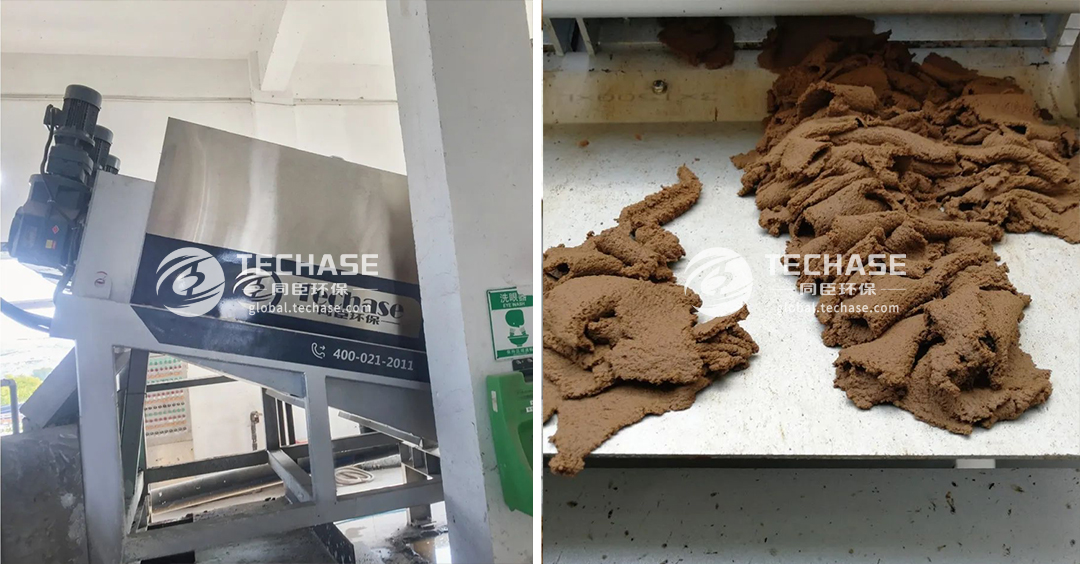

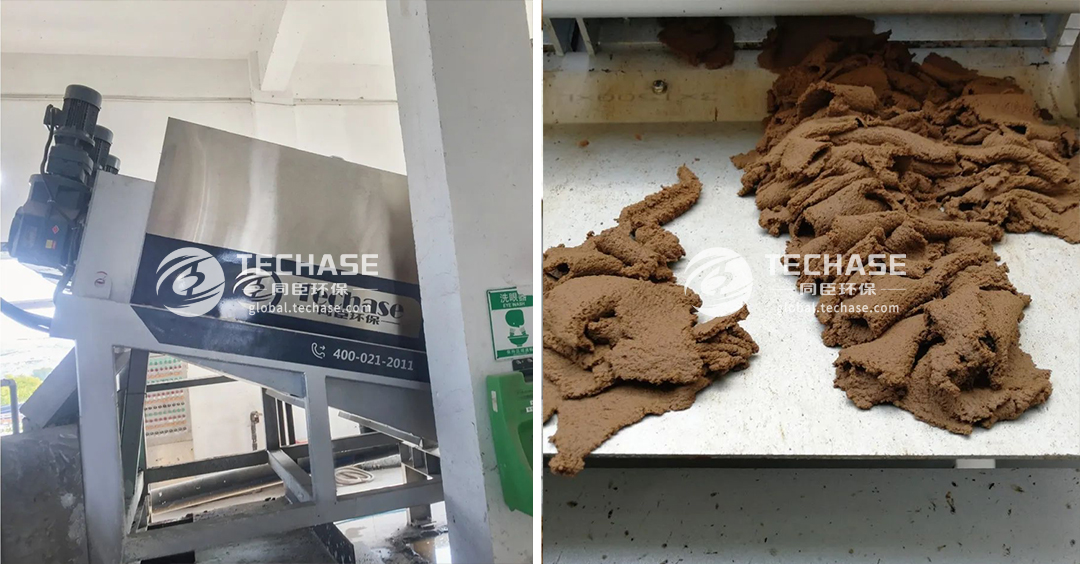

After systematic in-depth exploration and research, there are various treatment methods for landfill leachate at present, and each has its own characteristics, and choosing the appropriate treatment process according to local conditions will achieve twice the result with half the effort. Over the years, Techase has been actively exploring the field of landfill leachate, and the Techase® multi plate screw press produced has been widely used in many waste incineration plant leachate, landfill leachate, waste transfer station leachate and kitchen (kitchen waste leachate) ) biogas slurry and other projects, solved the problem of on-site landfill leachate sludge treatment and disposal, and played an important role in the entire operation process of stability and efficiency.

Techase® multi plate screw press has a remarkable effect in the sludge dewatering process of landfill leachate and is well received. As the main drafter of the multi plate screw press industry standard, the wide application of Techase® multi plate screw press lies not only in the technical advantages of the equipment itself, but also in its high-quality equipment quality and perfect after-sales service.

Related application cases

Shanghai Laogang Waste Incineration Plant Leachate Treatment Project - Phase III Project

Equipment model: TECH-403

Shanghai Laogang Waste Incineration Plant Leachate Treatment Project - Phase II Project

Equipment model: TECH-403

Baoding Waste Incineration Power Plant Leachate Treatment Project

Equipment model: TECH-404

Hechuan Domestic Waste Incineration Power Plant Leachate Treatment Project

Equipment model: TECH-353

Nanjing Jiangbei Phase II Food Waste Biogas Liquid Treatment Project

Equipment model: TECH-401

Equipment advantage

Equipment advantage

1. ANSYS model analysis, using industry-specific shafts, longer life and more stable mud effect

Because the water quality of landfill leachate is complex and harmful, it is different from general municipal sewage, and it is necessary to choose a suitable dehydration method in the treatment and disposal. In view of the characteristics of landfill leachate, Techase adopts ANSYS model analysis, adjusts the parameters of the screw shaft according to the characteristics of sludge, and introduces industry-specific shafts, professional technology blessing, to ensure the operation effect of the product, the final moisture content can reach 80% or even lower, stable reliable.

2. Fully sealed design, no peculiar smell on site, low energy consumption, low noise, and cleaner site environment

2. Fully sealed design, no peculiar smell on site, low energy consumption, low noise, and cleaner site environment

When it comes to landfill leachate, everyone's first impression may be the on-site environment with stench and odor. The Techase® multi plate screw press mud outlet can be equipped with a sealing cover configuration design, and the optional function of deodorizing port can be added to combine with the user's original deodorizing system; and the speed of the Techase® multi plate screw press screw shaft is only 2~4r/min, low energy consumption, low noise, cleaner site environment.

3. The equipment is self-cleaning, no blockage, and high structural strength

3. The equipment is self-cleaning, no blockage, and high structural strength

Techase® multi plate screw press fixed ring adopts uniform polygonal curved ring design to enhance the rigidity of the fixed ring; and the equipment has its own cleaning function, and the mud outlet is designed with a mud scraper, which can effectively prevent the mud outlet from being blocked and ensure the overall operation of the equipment It can effectively improve the solid recovery rate.

4. Simple maintenance and management, 24-hour automatic operation, no need for manual duty

4. Simple maintenance and management, 24-hour automatic operation, no need for manual duty

Techase® multi plate screw press is driven by an independent frequency conversion motor, the equipment can run automatically 24 hours a day without manual duty, and the maintenance of wearing parts is simple and convenient, which greatly saves on-site operation and management costs.

For the treatment of landfill leachate, my country is still in the development stage of continuous research and innovation. In order to build a green and harmonious environmental energy system, Tehcase will continue to forge ahead, continue to work hard in different industries with the entrepreneurial spirit of continuous struggle and innovation, and make continuous efforts to provide industry-specific products and solutions!

扫一扫咨询微信客服

扫一扫咨询微信客服