With the steady progress of the national epidemic prevention work, the construction of medical institutions in various places is in full swing. This has led to a significant increase in medical sludge production. As we all know, the waste generated by medical institutions has the characteristics of complex composition and high hazard. If not handled properly, it will inevitably lead to more serious consequences.

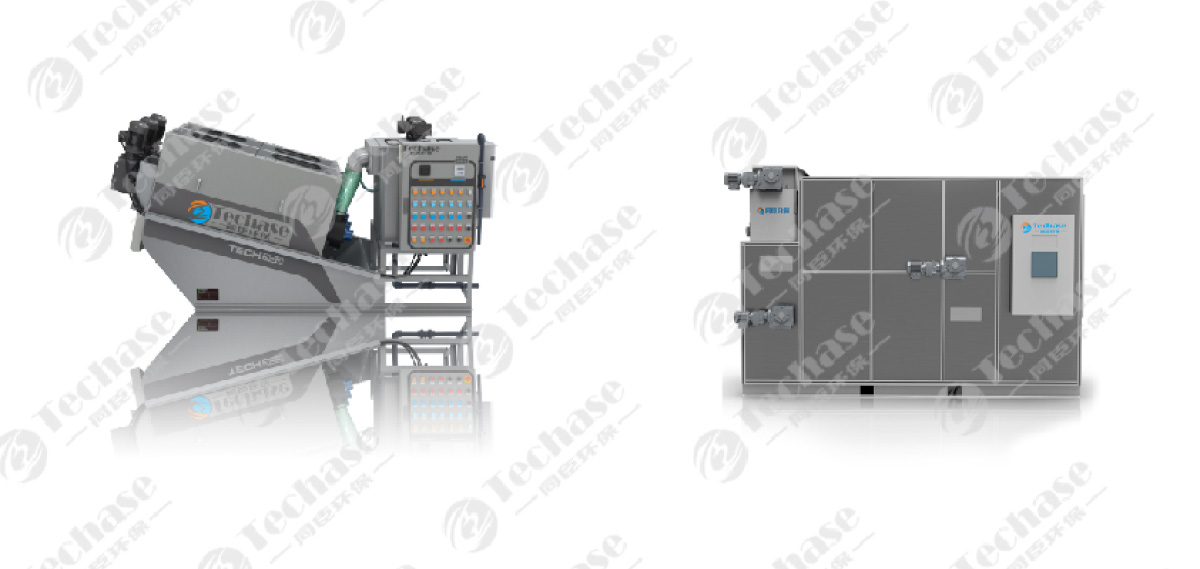

As a benchmarking enterprise in screw press industry, Techase worry about what customers worry, think about what customers think. Considering the characteristics of medical sludge, Techase has launched a special Multi Plate Screw Press Machine for hospitals, which was selected by the front line Wuhan Taikang Tongji Hospital and Xi'an Public Health Center (Emergency Hospital). Then, facing the new requirements in a special form, by what special features of Techase medical sludge Multi Plate Screw Press Machine have to stand out from similar products?

Integrated Seal, Automatic Operation

As medical sludge treatment equipment, the most important point is the safety of the treatment process. Techase Medical Dedicated Multi Plate Screw Press Machine integrates flocculation-thickening-dewatering all-in-one, without the need for supporting polymer station and dosing pump. The operation process is streamlined to minimize the possibility of the harmful substances such as bacteria and viruses to leak out.

At the same time, to avoid airborne virus transmission during sludge treatment. Techase Medical's dedicated Multi Plate Screw Press Machine adopts a fully enclosed mud inlet and outlet design, and it can run automatically without supervision. Completely eliminate the possibility of virus and bacteria transmission during sludge disposal.

Low Speed, Low Noise

As a medical institution, the noise of mechanical operation is a serious obstacle both to the rehabilitation process of patients and the daily work of medical staff. In order to effectively reduce noise, Techase Medical's dedicated Multi Plate Screw Press Machine adopts a low-speed working mode to effectively control the operating noise within 40-45 decibels. Provides patients and medical staff a quiet and comfortable medical environment.

Low in Power Consumption, Easy to Operate

During the outbreak of the epidemic, pressure on medical institutions increased sharply. Techase Medical's dedicated Multi Plate Screw Press Machine adopts low energy consumption design. A single device is only 0.7 ~ 2.5kw, which can be directly connected to the original power supply system without fluctuations and effects, without changing the original circuit design, and small size and small footprint.

Simple in Structure and Easy To Maintain

Techase special medical slduge multi plate screw press is simple in structure and convenient for disassembly and maintenance. Just through on-site and remote video training provided by Techase, you can quickly complete on-site maintenance of common faults. In case of problems that can’t be solved at the scene, Techase send our professional after-sales team to solve the problem quickly.

Unlimited Mobile Work

Techase special medical sludge screw press can be mounted on the Techase TCEM mobile dewatering system. Flexible operation locations, not limited to the site environment, drop and use. Especially suitable for square cabin hospitals.

In addition, Techase special medical sludge screw press can also be used in conjunction with Techase low temperature sludge dryer to further reduce the moisture content of the sludge and greatly reduce the processing cost. For other hazardous wastes, it also has excellent treatment effect.

In this anti-epidemic battle for the “2019-nCoV”, Techase will continue to shoulder its responsibilities, take demand as guide, serve customers, fight the epidemic!

扫一扫咨询微信客服

扫一扫咨询微信客服