On October 16-18, the world's largest professional exhibition in the fields of water treatment, environmental protection, waste treatment and new energy - the 7th India Environmental Protection Exhibition IFAT INDIA was held at the Mumbai Exhibition Center in India. The exhibition is hosted by the international exhibition giant MMI annually. Mr. Zhang Wenbiao, President of Techase, made a special trip to India to participate in the exhibition.

India is the second largest populous country in the world and also a member of the BRICS and SCO. As the largest developing country in the South Asian subcontinent, with the acceleration of India's economic development and urbanization, the demand for water from residents, industry and agriculture is increasing year by year, which will inevitably lead to more demand for water treatment related products, environmental friendly products and services in India. The disposal and utilization of solid waste and the development of new energy sources will also become important means for the sustainable development of the Indian economy. Therefore, Techase actively expands overseas markets, and with its excellent product technology and quality, it has established a good relationship with INCH-TECHASE of India and has become an in-depth partner. At present, Techase has more than 50 cases in India.

Mr. Jeekesk and Mr. Zhang Wenbiao

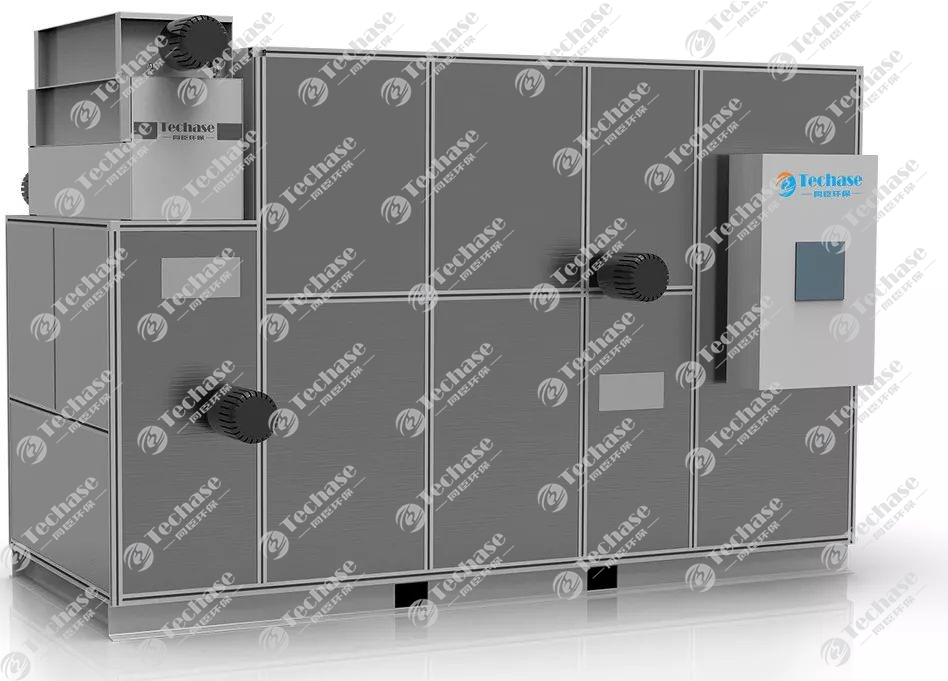

In response to the characteristics of the Indian market, Not only shown the traditional Techase multi-plate screw press and Techase vertical fiber cloth filter, we also exhibited the low temperature sludge dryer for the first time. And widely concerned by the participants. Compared with other sludge treatment equipment, Techase low temperature sludge dryer has the following characteristics:

Techase Low Temperature Sludge Dryer

01. System Safety

Sludge is dried below 70 ° C, the particle temperature is lower than 50 ° C, no dust, no explosion hazard. Low sludge discharge temperature (<50 °C), no need to cool, can be stored directly.

02. Technological Advancement

It adopts advanced heat pump dehumidification technology which is high efficiency and operation reliable. It can directly dry maximum 85% moisture sludge to 10% without segmentation; the whole process is automatically controlled, and the moisture content after sludge drying can be adjusted; there is no need to add other ingredients, and the dry material has a high calorific value, which is suitable for later resource utilization.

03. Process Economy

Under the premise of meeting the technical requirements of equipment use, select high quality products. Considering the initial investment and post-operational costs of the equipment for reducing the comprehensive cost to the lowest.

04. Energy Saving, Environmental-friendly

The technical processes in the “National Key Energy-Saving Technology Promotion Catalogue”, low-power equipment and products in the “National Energy-Saving Product Catalogue” is preferred; Selected low-temperature fully enclosed drying mode, no odor overflow, no need to install complex removal devices.

05. System Stability

The main components of the dehumidification heat pump sludge drying system are made by well-known domestic manufacturers.

Techase Multi-plate Screw Press

Techase multi-plate screw press is the fist product of Techase, its technology research and development capabilities and user cases are second to none in the industry. Compared with other similar products shown in this exhibition, the screw shaft length has increased 15%, and also established the ANSYS crush finite element analysis theory development model and sludge flow field analysis model. The blade is made of surfacing super-abrasive hard alloy material. After 6 steps of precision machining, it can be more wear-resistant with better dewatering effect and performance.

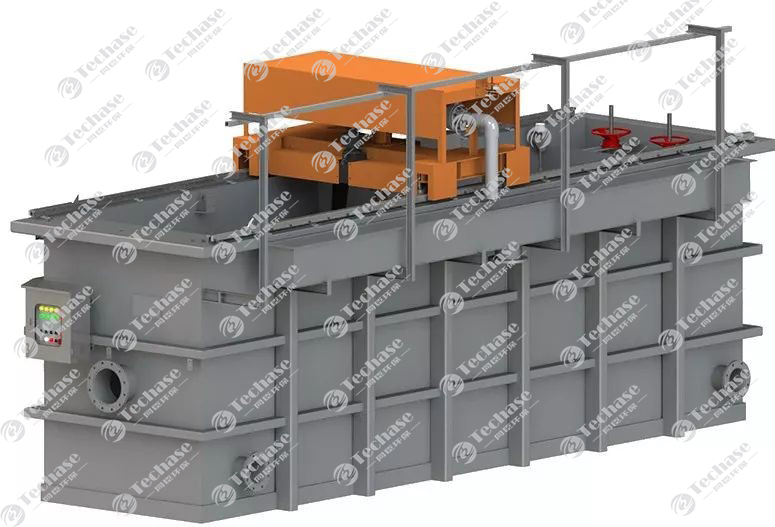

Techase High-efficiency Vertical Fiber Cloth Filter

Techase high-efficient vertical fiber cloth filter has the advantages of high efficiency, flexibility and reliability. Through the environmental protection technology advantages of Tongji University, it can systematically solve many indicators of the standard upgrading, such as combined with phosphorus removal. And with a backwash professional research design. The amount of backwash water is greatly reduced compared to the turntable filter, and backwash interval time required for the same effect is prolonged. Compared with the traditional sand filter, the operation cost is lower, the filtration effect is better, the maintenance is simpler, and the filter can be continuously filtered. It can easily handle a variety of work environments.

Environmental governance is an important issue with developing countries, especially those along the Belt and Road. As a leader of domestic wastewater, sludge treatment equipment and technical service provider, Techase will continue to shoulder the mission of "innovation, solving environmental problems and promoting green development", committed to China's intellectual creation. Contribute more power to the community of human destiny.

扫一扫咨询微信客服

扫一扫咨询微信客服