On August 16, 2019, the 11th Shanghai Water Seminar was grandly opened at the Crowne Plaza in Shanghai Pujiang. The theme of the seminar is “focusing on waste water quality improvement and efficiency, discussing application of system technology”, the seminar was co-organized by Shanghai Municipal Engineering Design and Research Institute (Group) Co., Ltd., Shanghai Chengtou Waste water Treatment Co., Ltd., E20 Environmental Platform and Tongji University Environmental Science and Engineering College. The seminar invited more than ten domestic top experts and scholars to explain the future development of waste water treatment. And invited dozens of leading companies of industry to share technical solutions for pipe network, standards improvement and sludge problems.

As the leading provider of sludge dewatering equipment and solution in China, Techases was invited to participate in this seminar. In response to the sludge treatment problem of this conference, Mr. Liu Daoguang, Vice President of Techase and Director of Technology Center of Techase, gave a speech in the topic of “New Sludge Deep Dewatering Treatment System”. With continuous green conditioning and fast high pressure press, full range of sludge treatment module equipment and processes provide a comprehensive sludge treatment system solution plan, which ultimately achieves the goal of sludge reduction and resource utilization. The speech caused great response and unanimous recognition from the participants.

New Sludge Deep Dewatering Treatment System

Industry Background

Sludge is the final product after waste water treatment. It is rich in organic matter, salt and a large amount of phosphorus, nitrogen and other substances from waste water, as well as toxic and harmful substances such as viral microorganisms and heavy metals. It can be said that sludge is a concentrate of pollutants in waste water, which can cause serious environmental hazards. At present, sludge treatment methods are various in China. The traditional sludge treatment method is to adjust the sludge after concentrate, and then adopt the belt pressure filtration dewatering or centrifugal dewatering technology, but the problem of low integration level of concentration and conditioning equipment and unstable sludge performance limit the development of sludge treatment process to a large extent.

Technology Introduction

The new sludge deep dewatering treatment system developed by Techase has been developed the technology new through the old. By continuous green conditioning of the sludge, with destroying sludge cementation structure, changing particle properties, the water holding capacity and filter resistance of sludge are reduced. At the same time, the process adopts a fully automatic control system, and is equipped with high pressure equipment such as super high pressure press, which can quickly reduce the moisture content of sludge to below 50% and achieve fast high pressure pressing. And the equipment is modular and integrated, which can greatly reduce the maintenance and replacement costs of the equipment. More importantly, the subsequent treatment of sludge is more extensive. The dewatered sludge can be turned into environmental friendly fertilizer by aerobic fermentation. The new sludge deep dewatering treatment system not only brings convenience to the subsequent sludge treatment, but also pay attention to the economic and environmental balance of the sludge treatment and disposal process.

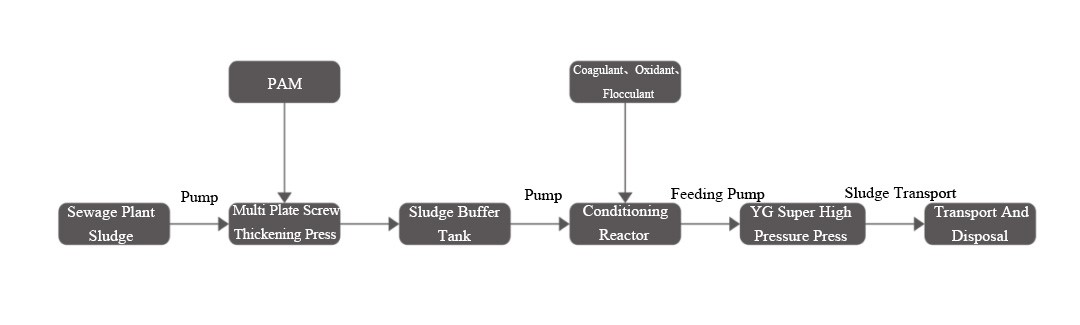

Sludge is concentrated in multi plate screw thickening press with PAM, and then placed in the sludge buffer tank; then pump into the continuous conditioning reactor for conditioning modification with adding powder-free agent; feeding pump sends the sludge to the super high pressure press for pressing treatment, the sludge cake after dewatering can be transported or recycled. For example, with aerobic fermentation, the sludge cake is fermented and used as fertilizer for land improvement, gardening and other fields. In order to achieve the goal of "turning waste into treasure."

Technology Advantages

1.High pressure pressing, low moisture content;

2.Integrated equipment, standardization, saving land area;

3.Environmental friendly liquid conditioning, no powder, which is conducive to subsequent resource utilization;

4.Fully automatic control system, simple operation and management;

5.Easy to design and construction, which is conducive to process adjustment.

扫一扫咨询微信客服

扫一扫咨询微信客服