Recently, Techase successfully won the bid for the Shaoxing Coastal Sludge Cleaning Disposal Demonstration Project with its excellent technical ability and rich engineering construction experience and also provides equipment and technical support for the project.

Shaoxing coastal sludge cleaning disposal demonstration project.

Project Scale

The construction scale of the project is to build a new 1×130t/h high temperature and high pressure circulating fluidized bed sludge incineration boiler and related supporting facilities, and focus on treating printing and dyeing sludge and sewage sludge in Binhai industrial area. Investment of the project is 800 million RMB and the sludge treatment scale is 2,500 tons/day, of which sewage treatment plant sludge is 1,700 tons/day, and printing and dyeing sludge is 800 tons/day.

Project Background

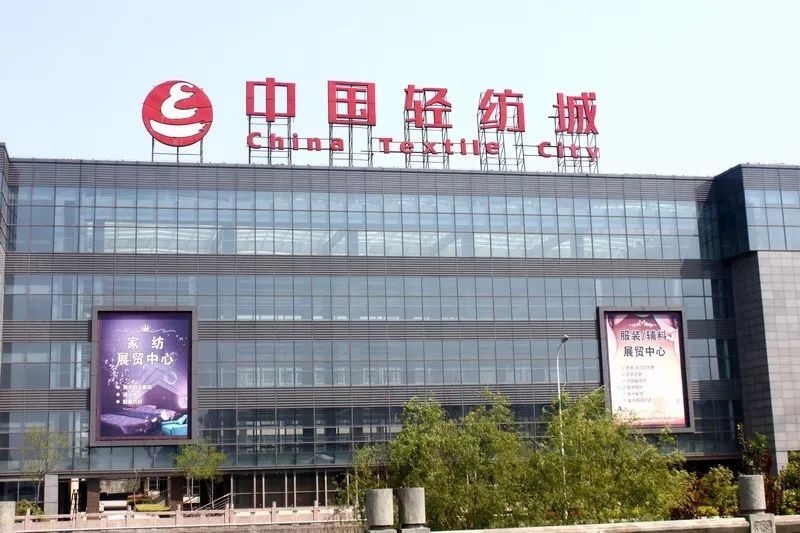

The project is located in Binhai industrial area, Ma'an Town, Keqiao District, Shaoxing. As an important municipal district of Shaoxing, Keqiao District is famous not only for its reputation as “Venice of the East”, but more importantly, it has the largest textile distribution center in Asia, called China Textile City. As the largest gathering place for printing and dyeing industry in Asia, Keqiao currently has more than 200 printing and dyeing companies. According to the government planning and industrial guidance policies, in the end of the “Thirteenth Five-Year Plan”, Keqiao District will no longer retain printing and dyeing enterprises in other places expect Binhai industrial area.

According to the survey results, Keqiao District currently has a disposal gap of 800 tons/day of printing and dyeing sludge, and disposal gap will expand with the future closure of the printing and dyeing plant except Binhai industrial zone and the expansion of the new printing and dyeing plant in the printing and dyeing area and the new sewage treatment plant, conservatively estimated will be 2,500 tons / day. In order to solve this problem, the Binqiao industrial area of Keqiao District decided to implement a sludge incineration project to incinerate the sludge produced by the dyed sludge and wastewater treatment plant.

Design Idea

After field investigation and sludge detection, the sludge property of the project is the remaining activated sludge after biochemical treatment. The organic matter content is high and the water content is large. The internal water and combined water are difficult to remove, which belongs to the category of difficult sludge treatment. According to the processing requirements, the sludge moisture content must be ≤50% for external transportation, which requires the selected treatment process to have a higher dewatering rate. According to the nature of the sludge and the treatment target, our process route is: sludge dilution + sludge conditioning + pressing. The core equipment is YG super-high pressure filter press independently developed by Techase.

Design Processing

1. Dilution: The external sludge is stored in the sludge collection tank, the sludge is grabbed into the sludge tank through the sludge grab, then the sludge is transported to the dilution tank, the sludge will be diluted from 80% moisture content to 92% moisture content by adding a certain amount of dilution water.;

2. Conditioning: The sludge is pumped into the conditioning tank by lifting pump, then feeding medicament to take further adjusted in the conditioning tank to change the high water holding property of the sludge, promote the separation of the muddy water and increase the intensity, so that the discharge sludge can get the modification requirements.

3. Pressing: The modified sludge is pumped into super-high pressure press for pressing to obtain a sludge cake with moisture content of 45% or less. The sludge cake is transported to the subsequent process section by conveying device.

Design Advantage

1. Large processing capacity, short processing batch cycle, fast feeding speed;

2. The sludge after dehydration has strong stability, high compressive intensity and excellent gas permeability;

3. High output solid content and no secondary pollution;

4. Compact design, no need for peripheral booster equipment, saving land and investment;

5. High level of mechanization, low energy consumption, easy to operate.

Based on promoting the development of the industry, the development goal of Binhai Industrial Zone is that fundamentally solving the environmental hidden dangers brought from the operation of the industry, and it is also the business philosophy of Techase. As an environmental protection company that has been developing for more than ten years, Techase has been committed to solving environmental problems for the majority of customers, promoting the steady development of the industry, casting lean quality with the spirit of artisans, and striving for the sustainable development of environmental construction and green energy.

扫一扫咨询微信客服

扫一扫咨询微信客服