Recently, I heard that a concrete company in Hong Kong has discovered a mysterious equipment. Its arrival has not only solved the problem of dewatering of concrete mud, but also realized the resource problem of wastewater reuse. What equipment is it? Why it can get the high praise of everyone? Let's reveal it together!

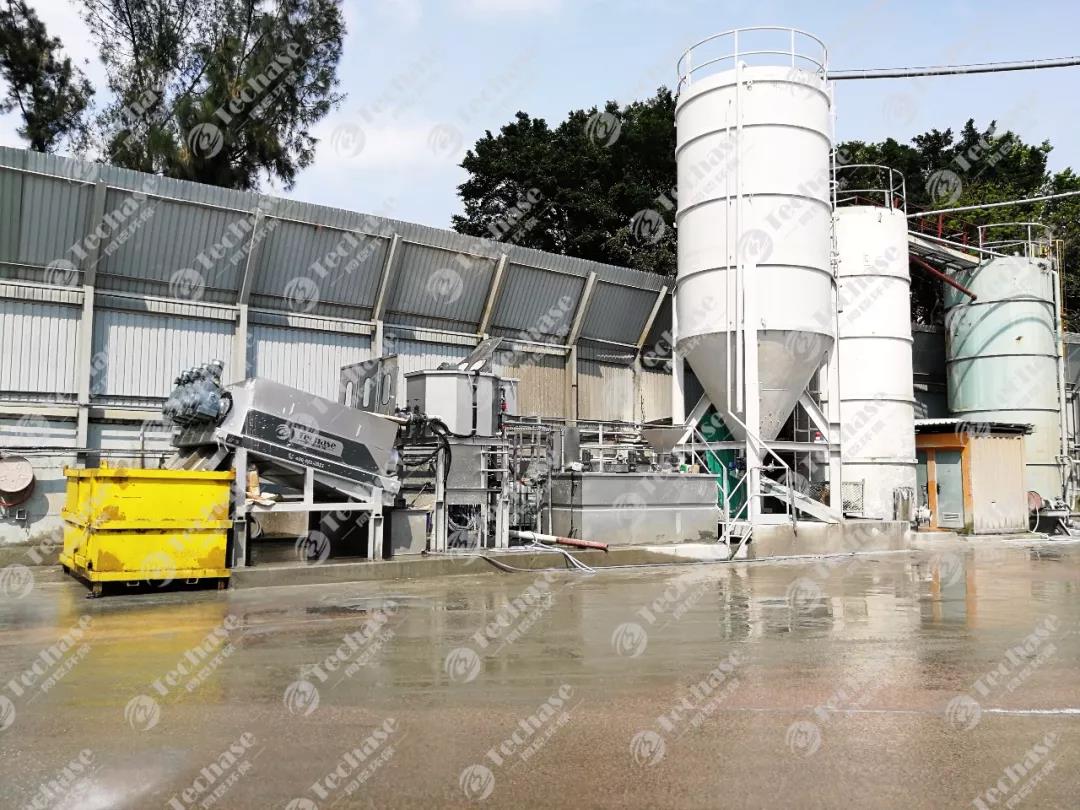

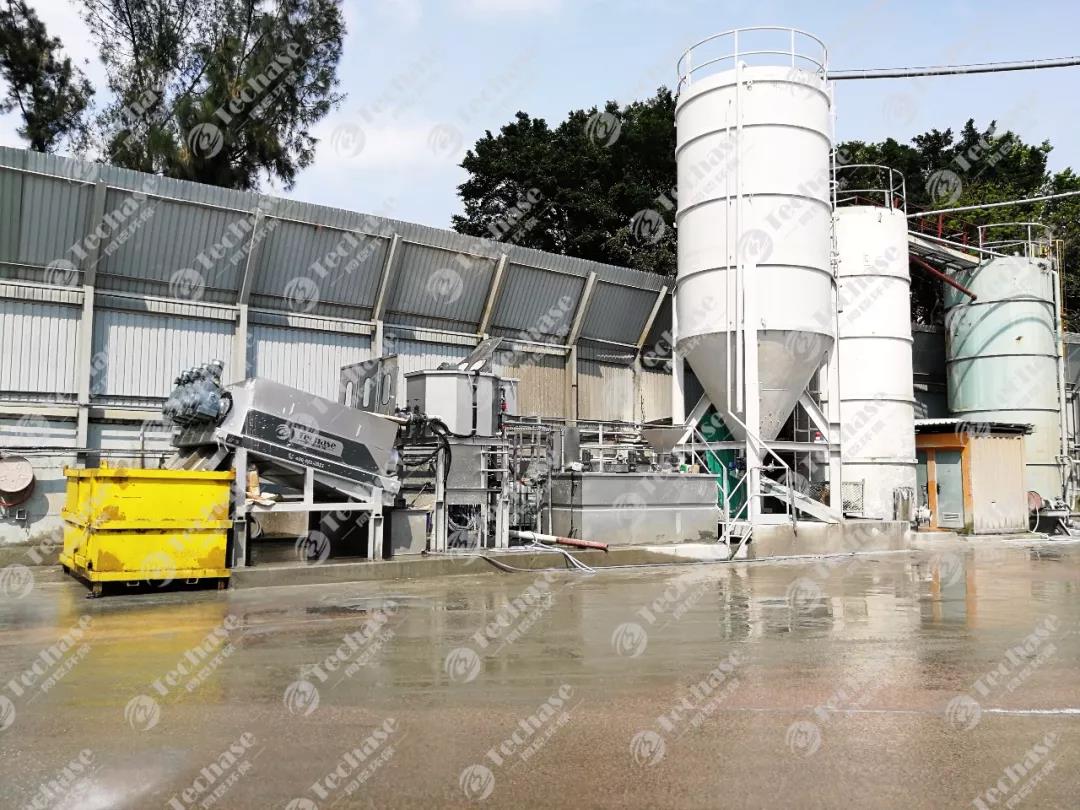

As the protagonist of the event, we will not repeat this mysterious equipment. It is one of the core products of Techase—Multi Plate Screw Press. The project is targeted at Hong Kong Jiahua Concrete Co., Ltd. as a vertically integrated model building material supplier. Its business mainly includes quarrying, crushing stone production, washing sand production, asphalt production, concrete and concrete prefabricated components. Production across the board, as well as supply of building materials for large government infrastructure projects.

In general, there is an essential transportation tool in the construction industry, that is, concrete mixer trucks. This type of truck is equipped with a cylindrical mixing drum to carry the mixed concrete, which is continuously agitated during transportation to prevent the concrete from hardening. After the transportation is completed, the inside is usually flushed with water to prevent the hardened concrete from taking up space and reducing the volume of the mixing drum. At the same time, how to treat the wastewater after washing the mixing tank with water becomes a headache problem. The wastewater after the wash of mixer truck contains a large amount of building mud, which has high density and difficult to handle. Direct discharge will cause environmental pollution, and it will also increase the transportation cost and cause a vicious circle. How to effectively treat wastewater and reduce production costs has become an urgent problem to be solved.

In the early days, Jiahua Concrete Co., Ltd. tried to solve this problem with a plate and frame filter press, but the traditional plate and frame filter press could not cure the disease. During the use process, the equipment has problems such as easy clogging, instability, and need more water to flush the filter cloth, which is not applicable to their previous expectations: the goal of both effective dehydration and wastewater reuse. Later, that company inadvertently learned that the multi plate screw press of Techase had these treatment characteristics, and contacted us in a sunny morning, so this story was born.

Treatment plan

After the concrete mixer truck is transported, the staff will rinse the inside of the mixer with water, and the waste water will be poured into the reservoir. After the sedimentation, it will be pumped into the water storage tank, and then connected to the multi plate screw press, the machine will began to officially carry out the dehydration operation. The treated water is recycled to the production and reuse, and completely realized recycling the wastewater. The dehydrated mud can also be used as bricks for building materials.

Processing flow

1. Flush the wastewater to the reservoir

2. After the reservoir is settled, it is hit into the water storage tank.

3. Connected to the multi plate screw press for dehydration treatment

4. The treated water is reused for production and utilization, achieving the goal of wastewater reuse.

Technical advantages

The equipment is stable in operation, large in processing capacity and low in noise;

Low water content, reducing mud volume and facilitating subsequent transportation and utilization;

The process energy consumption is low, equivalent to 20% of the energy consumption of the centrifugal dewatering machine;

The special screw for unique mud is more suitable for mud treatment with high inorganic content;

Simple operation and management, and small equipment footprint;

In order to meet the different needs of different industries, Techase combines its own technological advantages, strives for perfection and innovation, and tailored industry-specific solutions for customers. At present, a variety of industry-specific models such as petrochemical, fruit and vegetable processing, paper making, starch protein, and cyanobacteria dehydration have been introduced. Techase has always been committed to the sustainable development of green energy. In the future, we will work harder to provide more efficient and intelligent environmental protection equipment for our customers, solve environmental problems and promote green development.

扫一扫咨询微信客服

扫一扫咨询微信客服