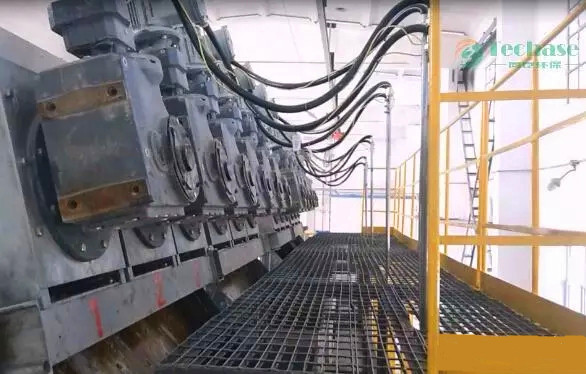

As the development of waste water treatment technology, multi-plate screw press, which is characterized by high efficiency, low consumption, low operating cost and high automation, has successfully captured a big share of waste water and sludge treatment market. We can foresee that it will gradually take the place of the traditional sludge dewatering equipment and be recognized by more and more customers in near future.

Techase as the first brand of this machine will never stop developing better screw and new material for this machine that keeps Techase always leading and pushing the technology development of this sludge dewatering industry.

Breakthrough in Theoretical Design

Techase is the first to build finite element model according to ANSYS screw shaft pressing theory. On the basis of the theory, Techase adjusted the parameter of the screw design and processing according to the characters of different types of sludge. This adjustment guarantees better application performance in different industries. So far, we have made so many breakthroughs:

400 Series Screw Shaft (Industry First)

Special Screw Shaft for Sludge Thickener (Exclusive)

Special Screw Shaft for Inorganic Sludge (Exclusive)

Special Screw for Petrochemical, Fruit & Vegetable Processing, and Paper Making Industry (Exclusive)

Innovation in Manufacturing Process

Techase is the first to use the super-hard wear-resisting alloy material and 6 surfacing processes in screw shaft while other manufacturers just spray a coating. This greatly improves the screw shaft of multi-plate screw press in wear resistance, anti-corrosion and heat resistance so that our machine well meets different requirements of customers. This material and process are usually used in high hardness and pressure field, such as tool making industry, drill manufacture industry, and so on.

Compared with common spraying coating, the wear resisting alloy material surfacing process makes the thickness of the wear layer 100-150 times improvement, the friction factor 80% lower, surface roughness 75% lower, corrosion resistance 90% improvement. Then the service life of the screw shaft can be prolonged more than 8 years.

Moreover,Techase has optimized the compression volume ratio of the front and back end of the screw shaft which make the ratio of the screw shaft more scientific. At the same time, Techase uses precision-machined nozzle in the sludge cakes discharge outlet which make the nozzle more accurate and difficult to be deformation. This means ensures better operation performance and longer service life.

扫一扫咨询微信客服

扫一扫咨询微信客服