The 13th China Urban Sludge Treatment and Disposal Technology and Application Advanced Seminar 2023, co-sponsored by China Water Supply and Drainage Association and TeChase, was successfully held during February 25-27, 2023 in Hangzhou, with over 1,000 participants of well-known domestic experts, scholars and enterprise technicians and visitors, aiming to effectively meet the disposal requirements of sludge " Refuse,Reduce,Reuse,Repair,Recycle " in China, and comprehensively improve the advanced level of sludge disposal technology, to conduct academic exchanges and share on the advanced technology, mature technology and operating experience on sludge treatment.

During the seminar, Dr. Song Yu, director of TeChase R&D center, deputy director of Shanghai Sludge Treatment and Recycling High-tech Equipment Engineering and Technology Research Center, and deputy director of Shanghai Sludge Low-carbon and Recycling High-tech Equipment Technology Innovation Center, presented 2 new developed advanced technologies 2023 of TeChase and gave a speech entitled "Innovation and Application of Full-process Sludge Treatment Equipment". From the discussion of industrial policies to the innovative equipment in the whole process of sludge disposal, as well as the project application of mature processes, the professional and detailed on-site sharing was warmly concerned and discussed by the participants.

Innovation and application of whole-process sludge treatment equipment

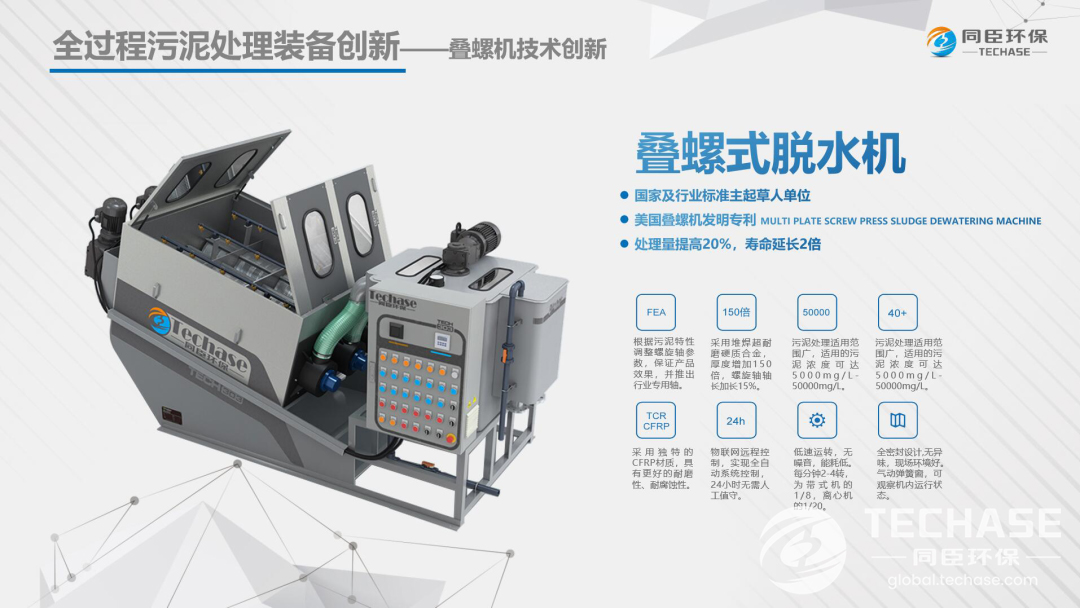

New Material - Multi Plate Screw Press

In terms of equipment innovation, TeChase has been pushing through the old to bring forth the new and constantly improving. On the basis of good quality, it is upgraded again, and the new material CFRP ring is adopted, which makes the equipment have a qualitative improvement in performance and quality. This carbon fiber reinforced composite (CFRP) is popular in the aerospace and military industry application, and is known as the "king of new materials". Its new application makes the screw stacker have longer service life, greater processing capacity, lower maintenance cost, and stronger environmental adaptability and corrosion resistance.

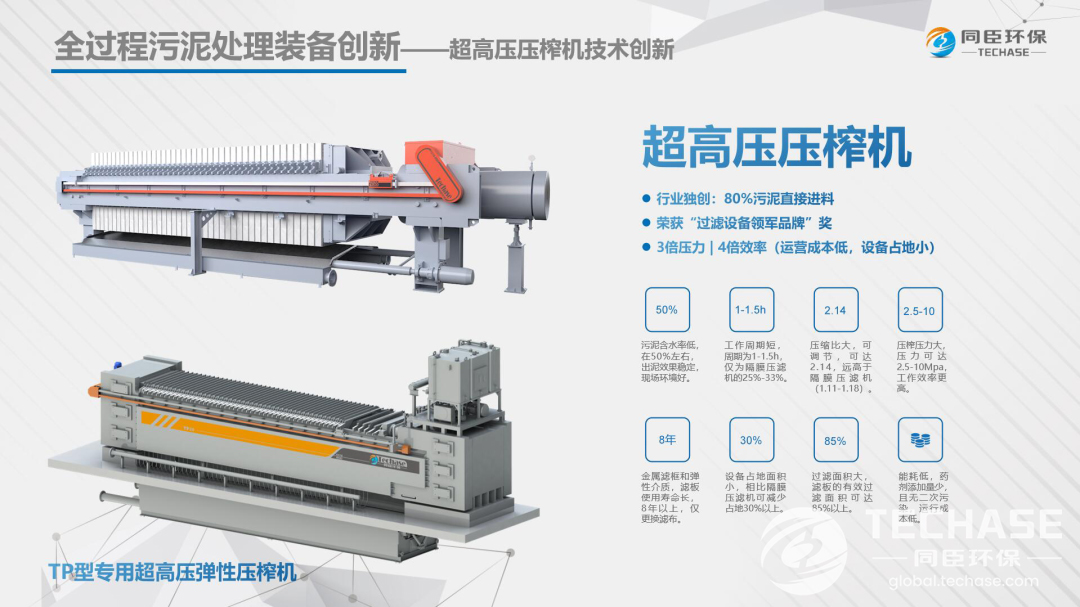

New Solution -TP Type Super High Pressure Filter Press

The equipment innovation and application of the super-high pressure press, in addition to the 80% M.C. sludge direct feeding process launched, TeChase keeps abreast in the field of coal chemical industry. Through a new technical upgrade, the TP-type special super-high pressure elastic press has been launched, with a maximum working pressure of 10Mpa, which is applicable for coal slime dewatering, chemical industry and other scenarios with higher dryness requirements. It’s stable and reliable in operation, long in service life, with high operation efficiency and intelligent Internet of Things system to realize continuous operation and maintenance and remote supervision services.

New Solution -Low Temperature Sludge Dryer

Since TeChase launched the low-temperature sludge drying machine, its market share has been expanding rapidly. The newly launched solar energy+waste heat technology innovation saves 30% of electricity through multi-heat source coupling. And the ash at the bottom of the mesh belt is automatically collected and sent out without manual participation, reducing the system maintenance work. According to different application scenarios in the sludge industry, the process and technology are constantly upgraded to achieve industry-specific advanced advantages.

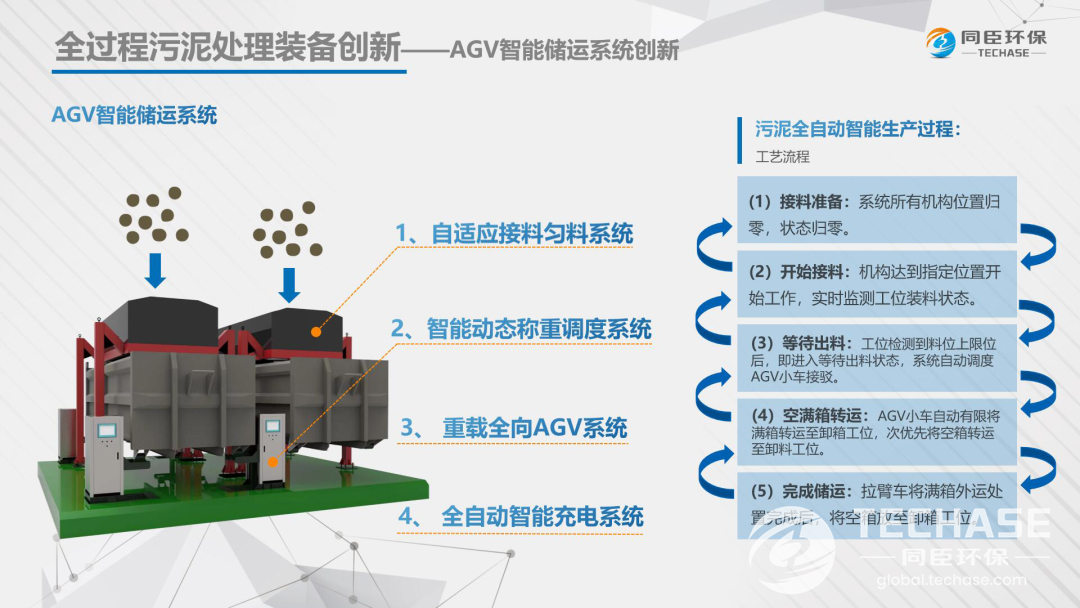

New Solution -AGV Smart Sludge Storing and Transporting System

As a new product system launched by TeChase, AGV sludge intelligent storage and transportation system helps to build a green and low-carbon intelligent water service through a series of intelligent operations, such as automatic navigation of intelligent robots, automatic placement and dropping of materials, automatic filling and transportation of bins out of positions, and full loading of sludge bins for transportation. It has advanced advantages such as zero labor and zero waiting, system energy saving of more than 70%, whole-process airtight and controllable, and sludge storage height reduction of more than 60%.

Typical Case Site Visit -YG Type Super High Pressure Filter Press TeChase Shaoxing Sludge Cleaning Treatment Demonstration Project

On the morning of the 27th, there was a site visiting of TeChase typical case study after the seminar. Around 250 experts together with TeChase team visited one of our Typical Case Site -YG Type Super High Pressure Filter Press-TeChase Shaoxing Sludge Cleaning Treatment Demonstration Project. This project is a sludge incineration project, with designed capacity 1700 tons of 80% M.C. municipal sludge. The adopted process route is sludge dilution+conditioning+pressing. The core equipment is TeChase® YG type super-high pressure press. The operation time is 20-24 hours, and the output moisture content of the sludge is ≤ 50%. The final dry sludge is directly mixed into the power plant for further incineration. Since operated in early 2021, our system has greatly solved environmental problems for our client.

扫一扫咨询微信客服

扫一扫咨询微信客服