Techase low temperature sludge drying technology is injecting circulating, warm and dry air to evaporate and take away the moisture in the sludge cake produced by sludge dewatering equipment such as multi plate screw press, plate and frame filter press, super high pressure filter press and so on to achieve the purpose of sludge weight reduction.

It is suitable for Municipal sludge and Industrial sludge such as pickling sludge, electroplating sludge, steelmaking ironmaking sludge, alumina sludge (red mud), oily sludge from oil fields and refineries, chemical and pharmaceutical sludge, papermaking sludge, printing and dyeing sludge and leather sludge, sludge weight reduction capacity of more than 70%, thereby greatly reducing enterprise production costs.

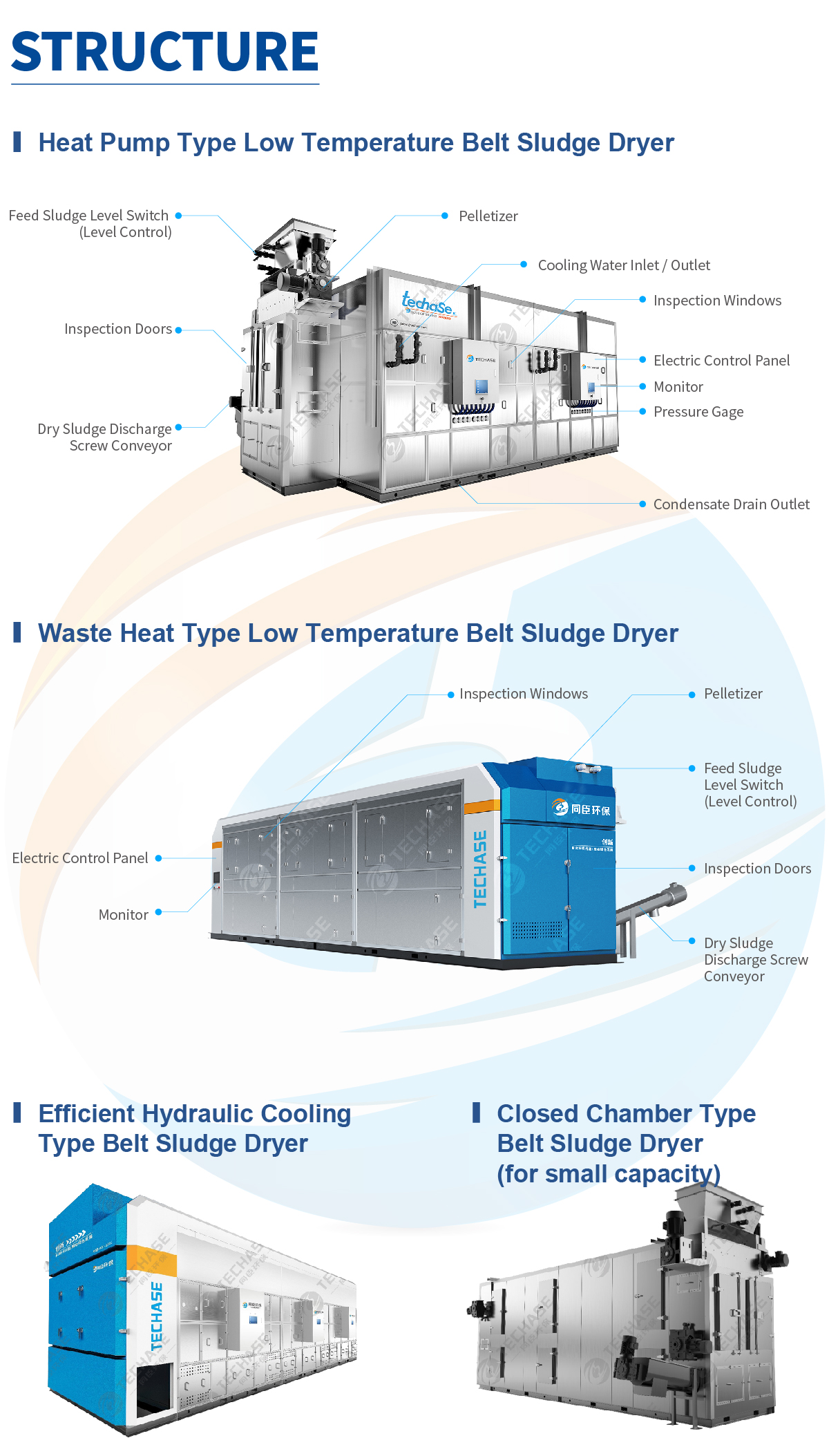

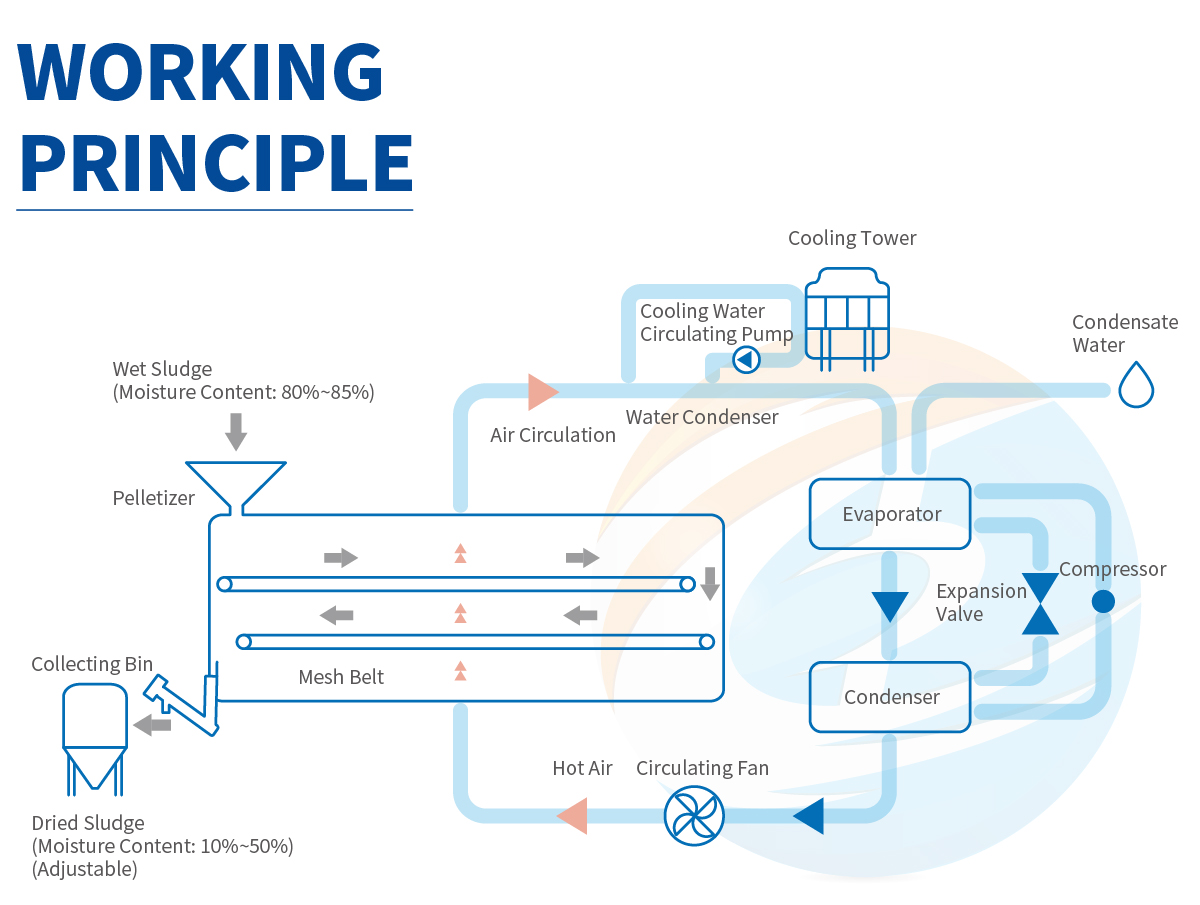

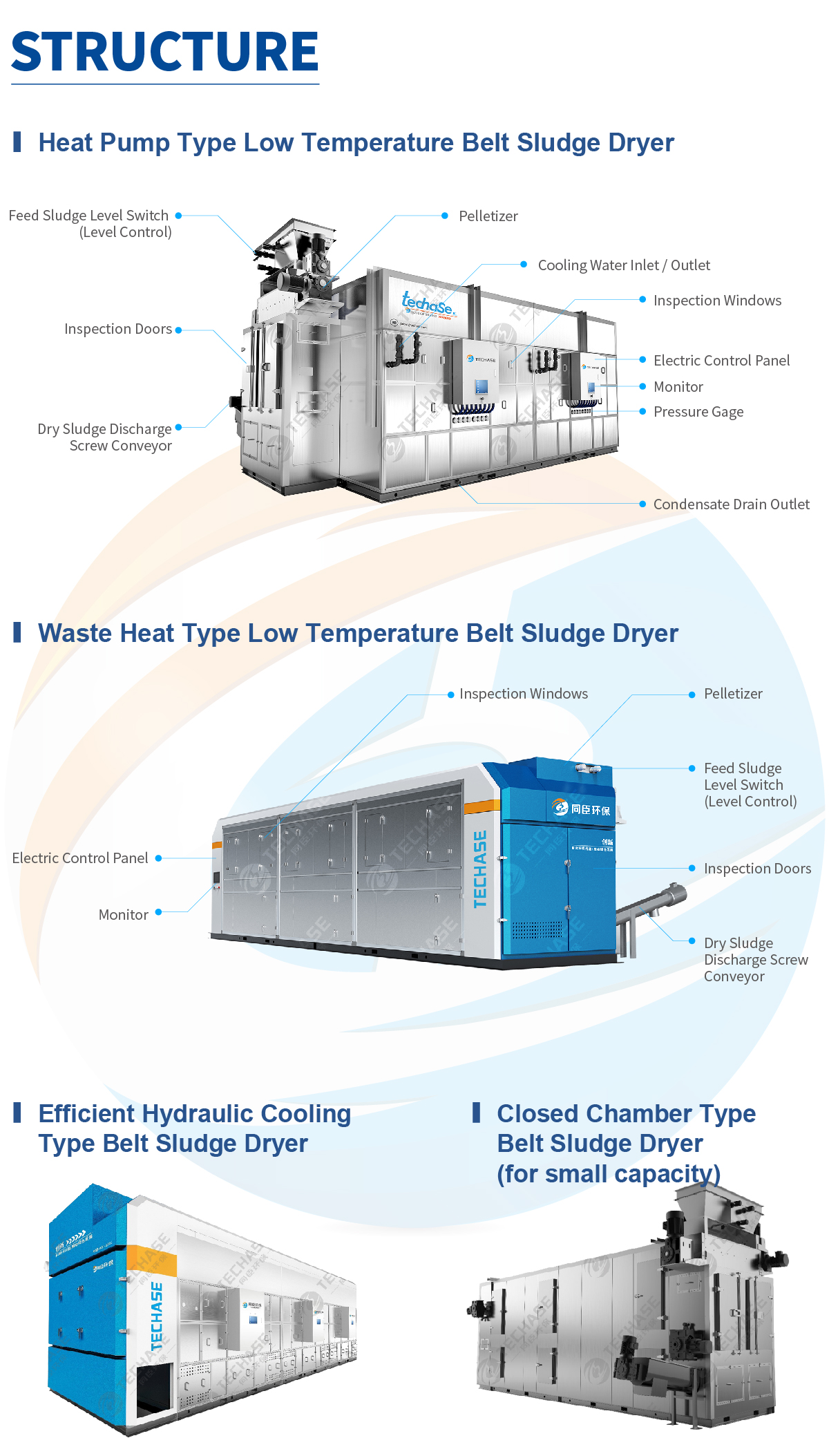

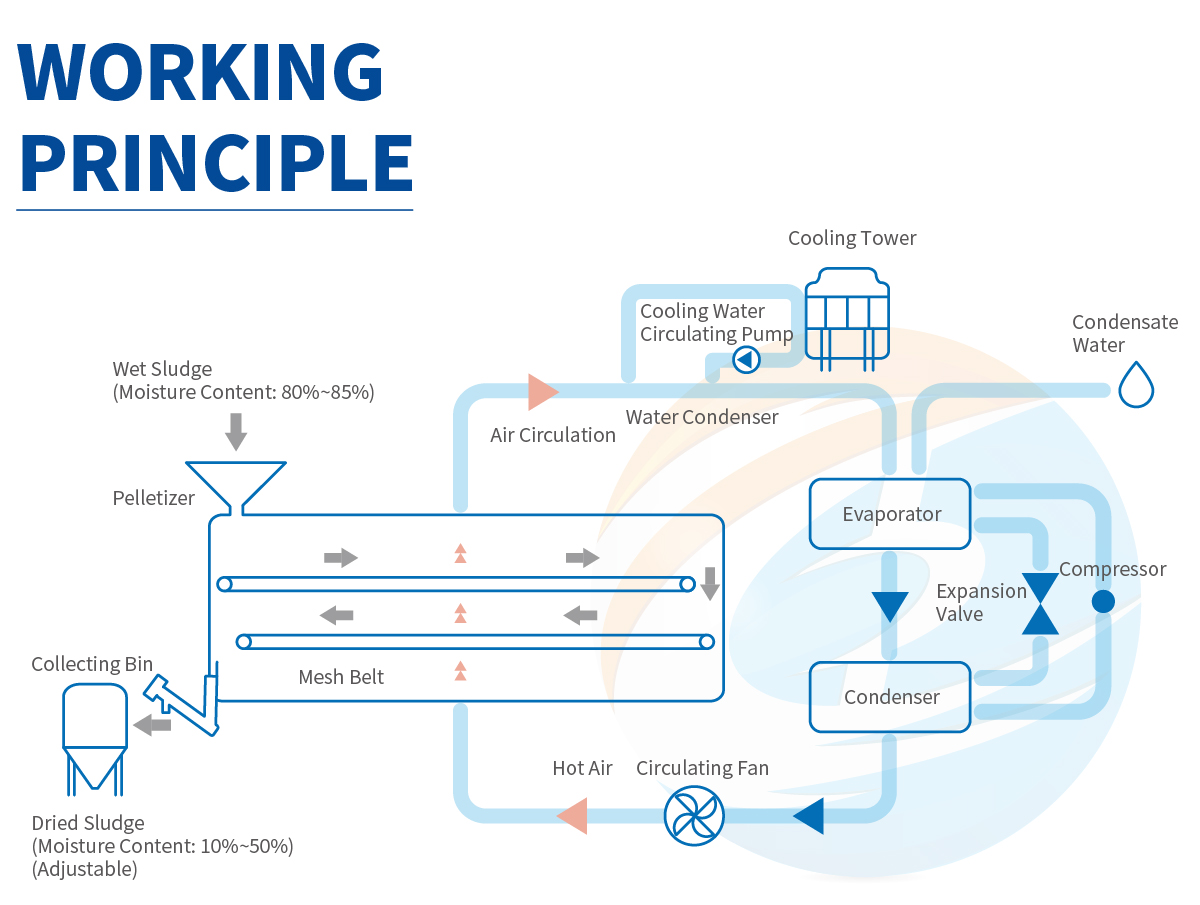

Techase low temperature sludge dryer uses the principle of low temperature heat pump dehumidification and convection hot air drying. After granulation, the wet sludge enters the low temperature sludge dryer. The sludge distributor in the equipment makes the sludge evenly distributed on the conveying mesh belt, and while being transported by the mesh belt, the water is taken away by the flowing hot dry air provided by the circulating fan, and finally the dry sludge is discharged. The flowing hot dry air increases the evaporation rate of the moisture in the sludge, and the large amount of water vapor is condensed and dehumidified. The dry air is heated again and participates in the sludge drying process, and the purpose of sludge drying reduction is finally realized.

There are multiple sets of temperature, pressure and humidity sensors in the low temperature sludge dryer to monitor and automatically adjust the operation of the device to ensure the dryness of the sludge discharge.

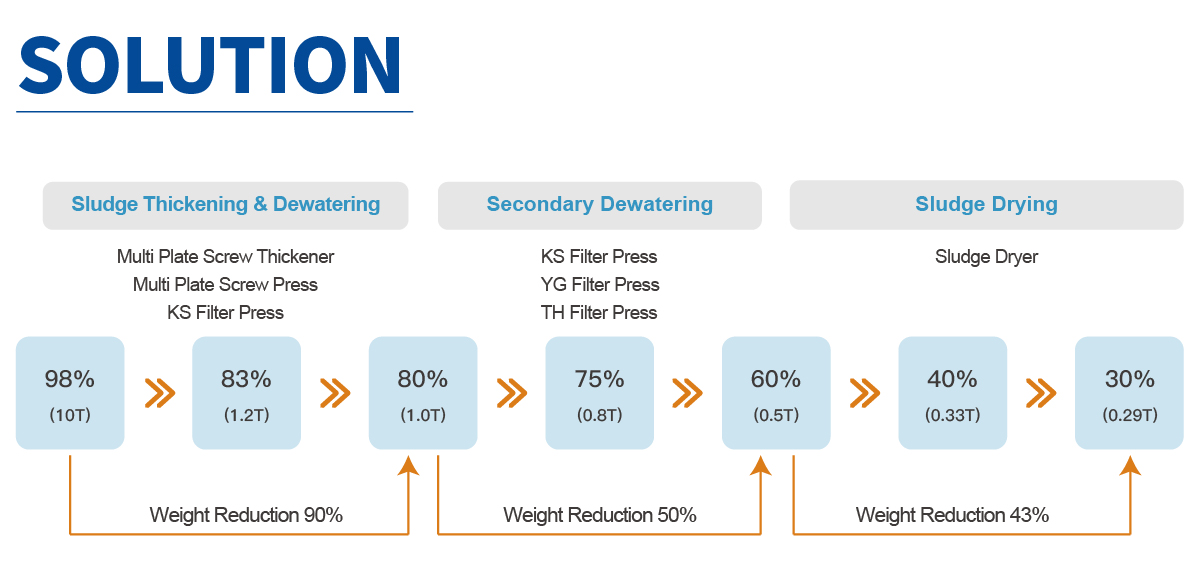

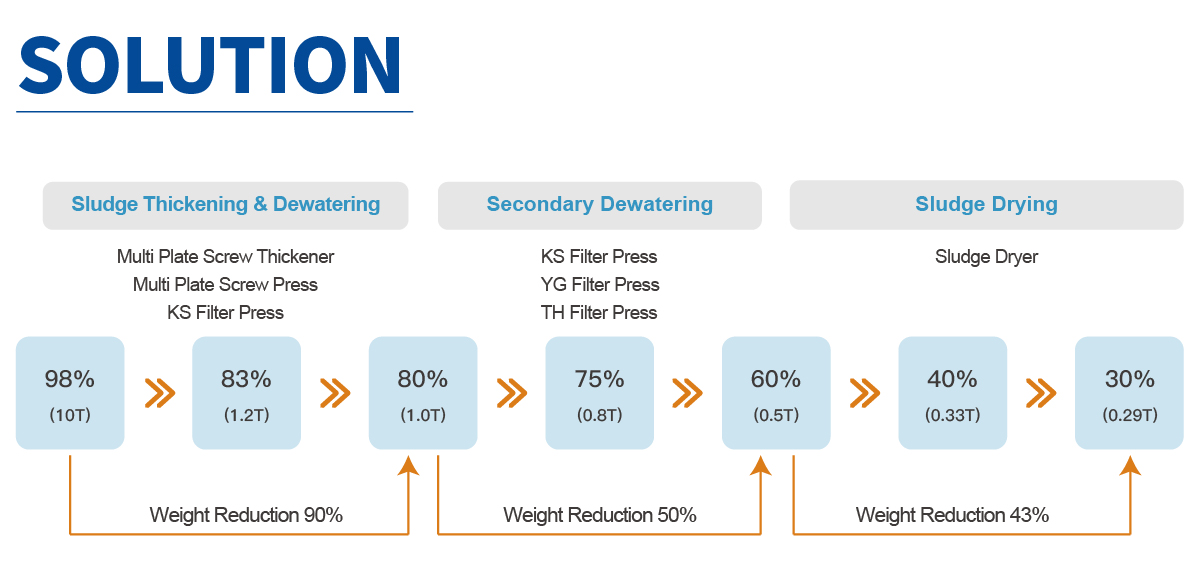

In addition to the research and development of low temperature sludge dryer, Techase has introduced a systematic low temperature drying solution through technological innovation. The sludge with high moisture content is processed through the multi plate screw press and KS filter press to reduce the moisture content of the sludge, and then the low temperature sludge dryer is used for centralized drying treatment. The whole scheme is efficient and convenient, and the sludge is discharged better effect.

扫一扫咨询微信客服

扫一扫咨询微信客服