In recent years, the stacked screw sludge dewatering machine has been greatly developed and promoted in China. Compared with traditional sludge dewatering equipment, the stacked screw sludge dewatering machine has the characteristics of non clogging, low energy and water consumption, and fully automatic operation. Currently, it has been widely used in many fields such as municipal, petrochemical, pharmaceutical, textile, metallurgy, food and beverage, agriculture and animal husbandry. With the development of new materials and control technology, Techase is also constantly innovating and improving, such as the research and application of unmanned shaft types, the "king of new materials" CFRP ring plates, and the Internet of Things.

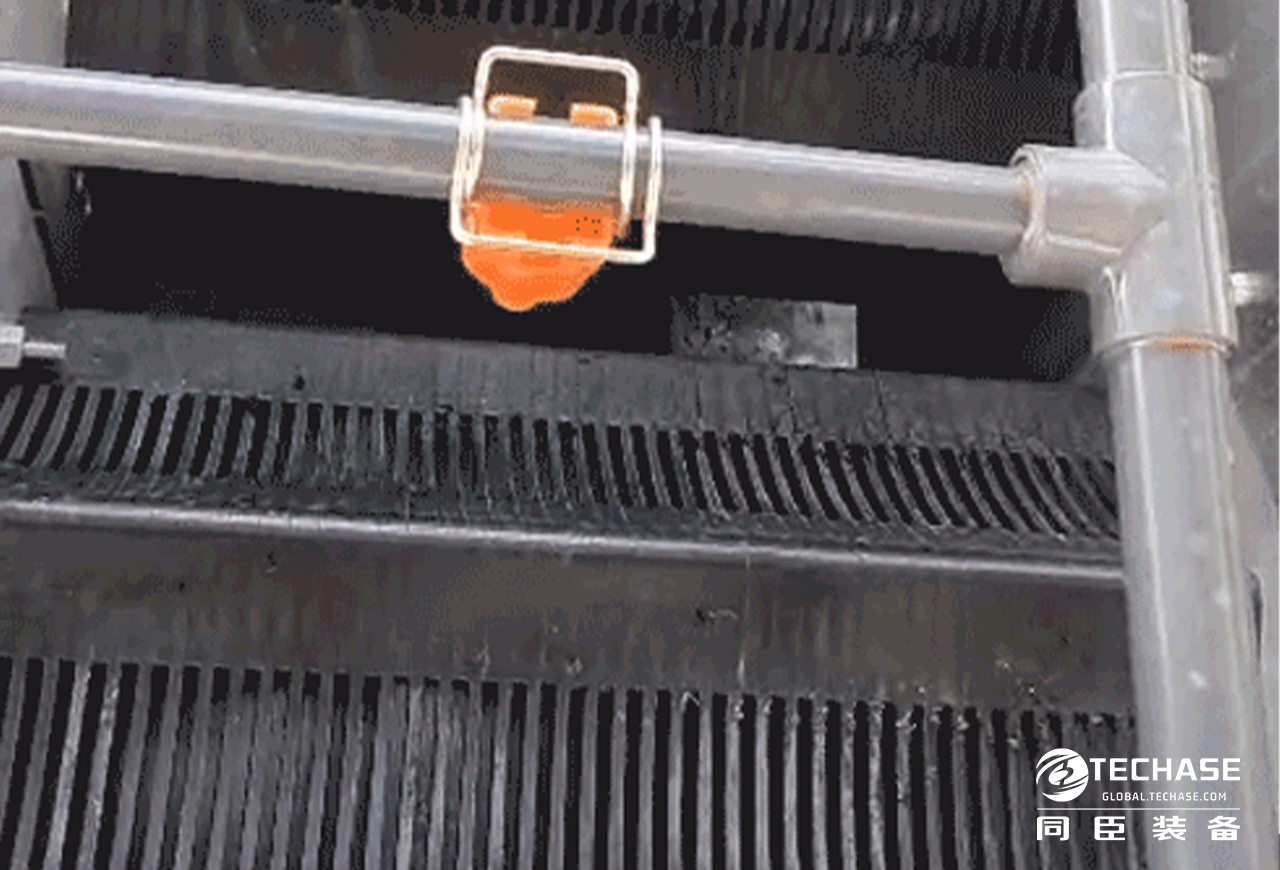

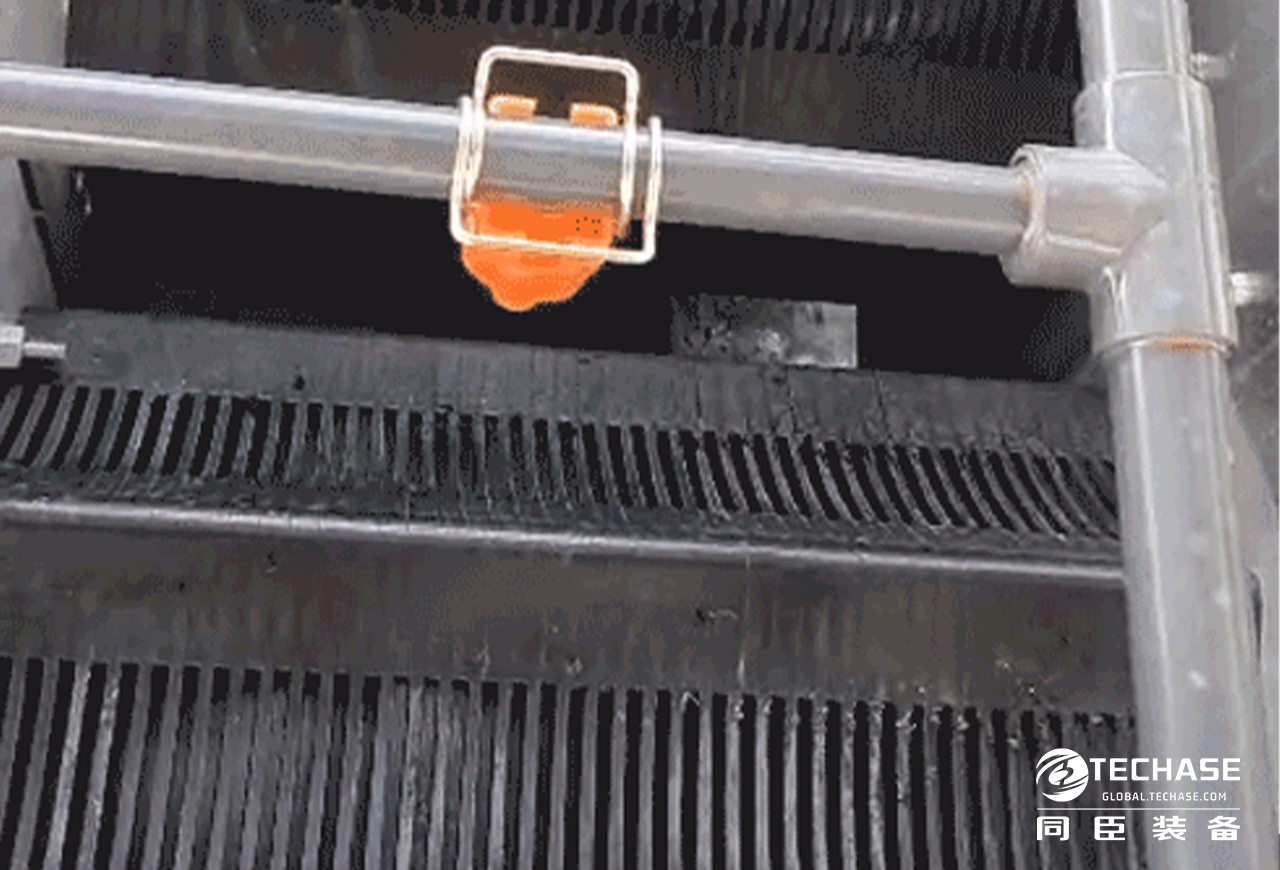

The case shared this time is the treatment of biochemical sludge in a pharmaceutical factory. The sludge dewatering system adopts a TC402 type stacked screw sludge dewatering machine and dosing device equipped by Techase. The sludge and prepared chemicals are flocculated in the flocculation mixing tank and enter the dewatering body. After treatment by the stacked screw machine, the moisture content of the sludge can reach below 80%.

In this project, Techase's stacked screw sludge dewatering machine received unanimous praise, with the following main advantages:

1. Fully automatic operation, continuous feeding and unloading, no need for manual supervision, can achieve remote one click start and stop, operation is worry free and labor-saving.

2. Energy saving and energy-saving, with extremely low operating costs. The speed of the spiral shaft is only 2-4 r/min, and the power of a single device is less than 3kW. Its average energy consumption is about 1/8 of that of a belt conveyor and 1/20 of that of a centrifuge.

3. CFRP rings have high-quality wear resistance, with a 2-year replacement rate of less than 5%, a service life more than twice that of traditional stainless steel 304 rings, and lower maintenance costs.

4. The spiral shaft is welded with a super wear-resistant hard alloy layer, and its welding thickness is 100-150 times that of ordinary spraying technology, greatly extending the service life of the equipment and reducing maintenance frequency.

5. In addition, the materials used in this project have a certain degree of corrosiveness, and CFRP rings do not react with acid, alkali, or salt, thus effectively exerting their high-quality corrosion resistance. Compared with 316 or even duplex steel rings, the use of CFRP rings not only improves product performance but also significantly reduces investment costs.

Strong product strength is the cornerstone of a company's long-term development. For many years, Techase has adhered to the principle of product as the core and quality as the foundation. We have made continuous efforts in equipment technology innovation, new material technology innovation, dual carbon technology innovation, and intelligent IoT technology innovation, working together to create user-friendly, practical, and highly reliable products and solutions, creating greater economic and social benefits for users and solving environmental problems.

扫一扫咨询微信客服

扫一扫咨询微信客服